Methods for connecting segments of LED strip

Method number 1- Using connectors

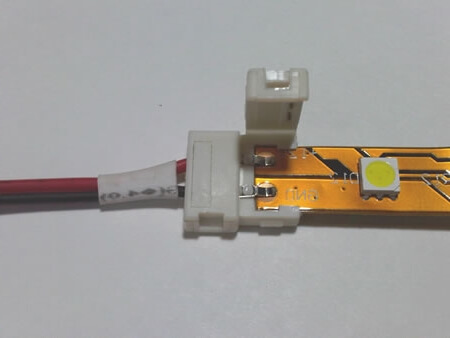

The easiest way is to connect two segments of a single-color or RGB tape in series using special connectors. Everything is quite simple - you need to prepare the contacts and snap them into a special connector. In order for you to understand how to make the connection correctly, we provide step-by-step instructions:

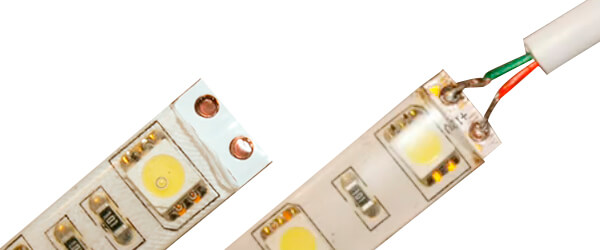

- If necessary, cut off the desired piece of LED strip. Cut led strip need in special places, as shown in the photo below:

- Further, if the contacts are in silicone, you need to carefully remove it. In order not to damage the contacts, it is recommended to make a perpendicular incision in a suitable place and peel the silicone from the end.

- Observing the polarity, you need to put two segments in the connector and connect the LED strips to each other.

We recommend that you watch the video instructions for using the connectors:

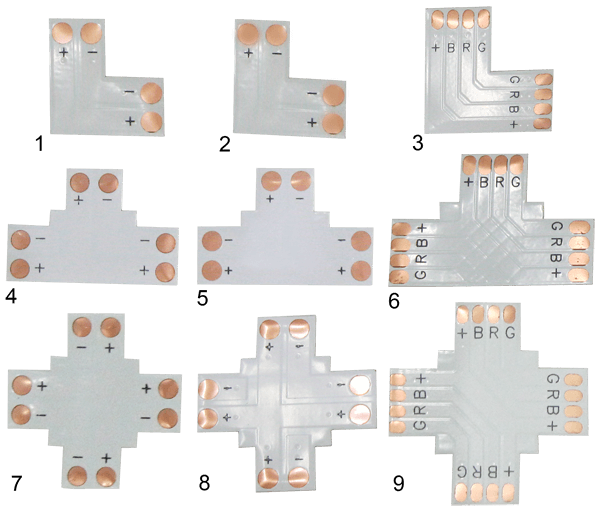

We draw your attention to the fact that with the help of special corner connectors you can even fasten several segments into one large one at a right angle or 45 degrees. This is very convenient, especially when there is a need to make lighting at the corners, for example, around the perimeter of the ceiling. To date, the following types of connectors can be found on sale:

I would also like to note an important nuance - do not forget that if you want to consistently connect segments into a strip of more than 5 meters, you need to take into account the power of the power supply and the advisability of such an idea. We recommend that you first familiarize yourself with LED strip connection schemesso that in the future you do not have problems in the backlight.

Method number 2 - Soldering iron

If you need to connect two pieces of LED strip, and there are no special connectors at hand, you can solder the segments. To do this, you must first be able to to solder wires correctly. Instructions for connecting LED or RGB tape by soldering are as follows:

- Prepare the LED strips for the connection, namely, strip the contacts and degrease the surface.

- Strip the ends of the wires approximately 10 mm. By the way, in order to solder segments, you can use ShVVP cord.

- Clean the soldering iron and turn it on.

- Run tinning lived and treat the contacts on the tape with special acid.

- Put solder on the contacts.

- Press the tinned wires to the connection and warm them up slightly with a soldering iron.

- Insulate the solder with a glue gun or at least electrical tape. You can also use a shrink tube.

In this way, two pieces of LED strip can be connected in series using soldering. In this case, you can also solder the segments and place them at an angle of 90 degrees or less / more. An important point is that you need to warm up the contacts very quickly with a soldering iron, while the temperature should not exceed 300 degrees so that the conductor does not burn.

Finally, we recommend that you read the instructions for connecting products by soldering:

That's all I wanted to tell you about how to connect the LED strip between each other with connectors and soldering. We hope our tips helped to understand this issue!

It will be interesting to read:

Hello.

In the kitchen there are 2 lockers, I want to make an LED strip under each of them, but to turn it on from one switch. The problem is that the distance between them is 1.5 meters. How can I connect two tapes? In general, at such a distance is a connection possible?

Thank.

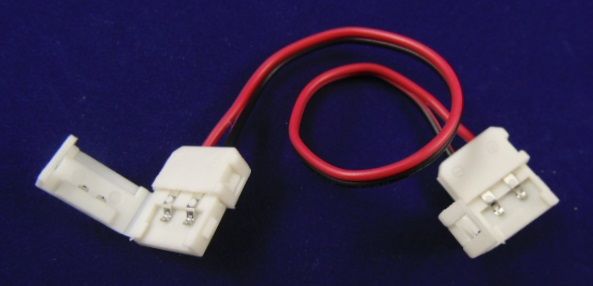

If you carefully read the article, you would surely notice a connector with a wire at the end of the description of “METHOD No. 1”. Such a connection can be cut and pasted into it a wire of any length in a way convenient for you. but it’s better to solder a piece of wire directly to the tape and connect what you need.

Thank you for the answer, but none of the methods indicated the possible length of the connecting wire.

I was not in vain writing about 1.5 meters.