Learning to solder wires - consideration of all the nuances of soldering

Step 1 - Preparing the Tool

First you need to prepare a soldering iron for soldering wires with your own hands. All that is required is to thoroughly clean the tip from the remnants of solder or other possible contaminants.

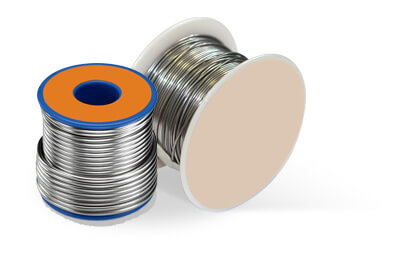

You can use a regular file for this. In addition, you must prepare solder and flux, without which it will not be possible to solder the wires with a soldering iron. As for solder, in order to solder the wires, you can use either an alloy of tin and lead, or a special thread, as shown in the photo below.

The flux is necessary so that during soldering the solder evenly covers the soldered materials. In addition, the flux relieves the copper conductors from the oxide film, which significantly impairs the reliability of the connection. As a flux, you can use either rosin or special soldering acid. Both that and other option is popular among masters.

Another important stage of preparation is the creation of a suitable workplace. You should have a socket and a stand for a soldering iron nearby so that the technology of soldering wires with your own hands is safe.

By the way, you can DIY soldering ironthat does not take much time and effort. A homemade device will last you quite a while, as you yourself can see!

Step 2 - Tinning

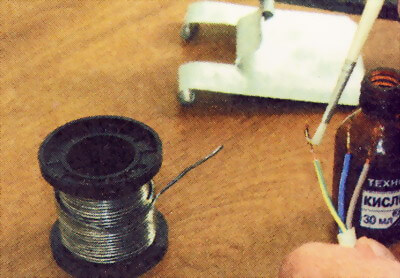

So, if you need to solder the two power wires together, then the first thing you should do is to remove the polyethylene insulation and tin the exposed wires, especially if they are very thin. The stranded conductor before brazing is first twisted, after which it is processed with a flux, on top of which a thin layer of heated solder is applied. Be sure to prepare a soldering iron tip before soldering - dip it into the flux (in the same rosin as shown in the photo), and then into the tin so that the tip is covered with a small layer of solder.

Wire tinning for soldering, it is quite simple to perform - first you need to put the bare core on the rosin, then warm this place with a soldering iron so that the wires are immersed in the flux.After this, it must be removed and treated from all sides with solder. To apply a hot alloy of tin and lead to the surface, scroll the wire in your hands while tinning. If you need to connect the conductors in a junction box, you can use acid instead of rosin for convenience. It is enough to simply apply it with a brush on the surface that you need to solder.

If the conductors are large (thick), tinning is performed in a similar way. The only difference is that you do not need to pre-twist the wires, as in a multi-wire conductor.

After you have tinned, you can proceed to the soldering process. Immediately draw your attention to the fact that work is only necessary when the power is off. Soldering live wires is strictly prohibited!

Step 3 - Solder the Veins

Well, the last thing left is to solder the two prepared wires in the distribution box. All you need is to twist or lay the wires on top of each other and warm up the junction with a soldering iron. The solder will melt and after it hardens - reliably connect the electrical conductors. Tips forjunction soldering in a junction box we considered separately.

An important point - during soldering, do not move the wires, otherwise the connection will not be reliable enough.

It should also be noted that preliminary tinning can not be performed, but simply twist the wires in the junction box, process them with flux and properly solder them. However, we do not recommend you soldering this way, because in this case the connection will be an order of magnitude worse.

The final touch is the isolation of the cooled area. About, how to insulate wires we told you. It is best to individually insulate each core with electrical tape, and use a heat shrink tube on top of it. In the video below, you can view in detail the entire soldering order:

It's important to know!

Above, we talked about how to properly solder the wires in the junction box, but this procedure will not work if you need to solder the contacts with the diode tape or even on the board (microcircuit). So, we provide a brief overview of possible soldering technologies:

- LED strip connection. If you need to connect an LED strip, which means to solder the contacts from the power supply with the leads on the tape (copper circles), first tin the wires plus and minus, then treat the leads on the tape with acid and drip molten solder onto them. All that remains is to press the wires to the junction and warm them with a soldering iron. When the solder hardens, insulate the exposed area using a glue gun or heat shrink.

- Work with boards. If you decide to solder the wires on the chip, then here the soldering technology will be more responsible. To solder a capacitor, transistor, resistor or the same LED, you need a soldering iron with a power of 5 to 20 watts. A more powerful device can overheat the board and then your efforts will be in vain. In addition, the sting should be very thin, because surplus tin will act as jumpers, which in turn will be "short."

- Soldering headphones. If you suddenly decided to repair headphones with a 3.5 plug, which often break in the area of the connector, then first watch a video on the Internet that tells how to learn how to solder enameled thin wires with silk thread inside. In short - you have to clean the enamel to copper, perform tinning and after that only solder the plug with the wiring.

This completes the technology of independent soldering. We hope that now you know how to solder wires of large and small cross-section at home!