Simple technology for building wires and cables

The main ways to build

To begin, consider how to extend a wire or an electric cable at home. If the conductors of both spliced conductors are of the same metal (copper or aluminum), then the following extension methods can be used:

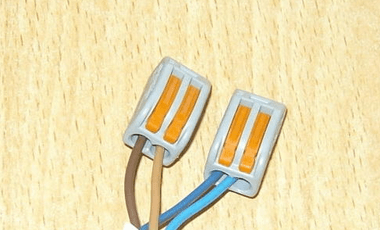

- Using terminal blocks Wago. The most convenient option is not only building, but also electrical wire connections. It is recommended to use even in that situation if the conductors are made of various metals. The main condition for their use is to connect circuits in which the current does not exceed the rated voltage indicated on the terminal block. We advise you to buy them in "proven" places and not flatter yourself at low cost - the market is oversaturated with fakes that melt and burn.

- Budget connection blocks, the so-called polyethylene terminal blocks, allowing you to extend the wiring. The peculiarity is that with a strong tightening of the monolithic core, the metal part of the terminal block cracks. They can not connect stranded wires. To do this, they need to be tinned or crimped with a tip type NSHVIto get reliable and durable contact.

- Twisting lived. Grandfather's method, which is one of the most unsafe, but at the same time popular even among experienced electricians. To increase the wiring by twisting, it is necessary that the broken end be at least 30 mm (for reliable splicing). About, how to do the twisting of wires read in the corresponding article. Know that twisting is prohibited according to PUE 2.1.21. Therefore, do not use this method in its pure form (without crimping with a sleeve or PPE, soldering or welding).

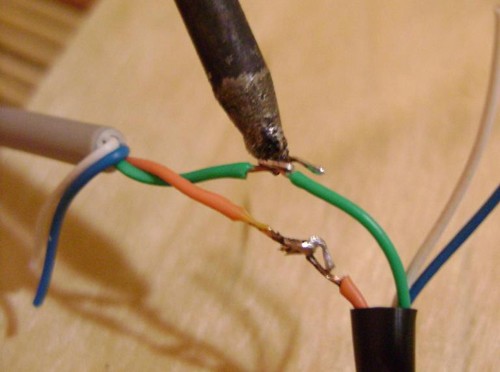

- Soldering. Another option for lengthening the wiring is the use of soldering. If you know how to use a welding machine, this method will allow you to qualitatively increase the conductor even of a large cross-section (4-6 mm.kv.).

- Sleeves. Crimping with sleeves - This is a great way to connect and is well suited for cable extension. But to build a dangling wire in the outlet, you may not have enough space.

- Nut or other similar branch clamps. With their help, branches are connected to enter private houses from VLEP. Also suitable for extending wires. The main disadvantage is the large size.

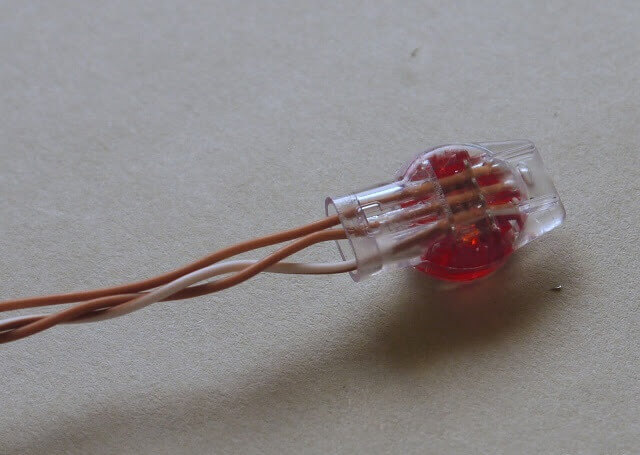

- Scotchlocks - Great for tapping, connecting and extending low-current wires.They can be used to connect 220V circuits, but are better suited for data lines, such as twisted pairs.

We draw your attention to the fact that it is possible to extend aluminum conductors with copper only if a special terminal is used for splicing. All other options to increase the line, it is strictly forbidden to use! Read more about connecting aluminum and copper wires in the article: https://our.electricianexp.com/en/kak-soedinit-alyuminievyj-provod-s-mednym.html.

So we examined what methods exist for building up electric wires at home. Further to your attention typical cases will be provided when you need to extend the wiring yourself, and now we recommend that you watch the visual video instruction:

Most common situations

So, now we will proceed as follows: we will consider each specific case that may occur in everyday life, and immediately provide instructions on how to properly increase the wire and cable.

Situation 1 - Broke a vein in a wall or ceiling.

Veins often break in the socket or in the place of attachment of the chandelier. As a result, the devices do not work. It would seem that the simplest task is to restore the supply of electricity you just need to connect 1 vein. But when stripping, you realized that this could not be done due to lack of length - the core had broken off “under the root”.

You also have to do this if you decidetransfer socket or a switch to another place and during electrical work one of your wires broke off, then you need to act depending on the situation that has arisen.

If the length of the core remaining on the surface is sufficient for extension, install the terminal block and extend the short conductor with the same cross-section and material. If there is a very short conductor left in the wall - break up a section of the wall, release a sufficient length of the power cable for extension, strip the core to a metallic color and extend the section.

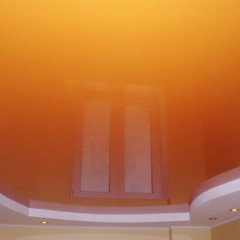

So you can and increase the wiring in the junction box or on the ceiling forconnecting chandelier or any other lamp (for example, a sconce on the wall).

Situation 2 - You need to build up the cable in the water.

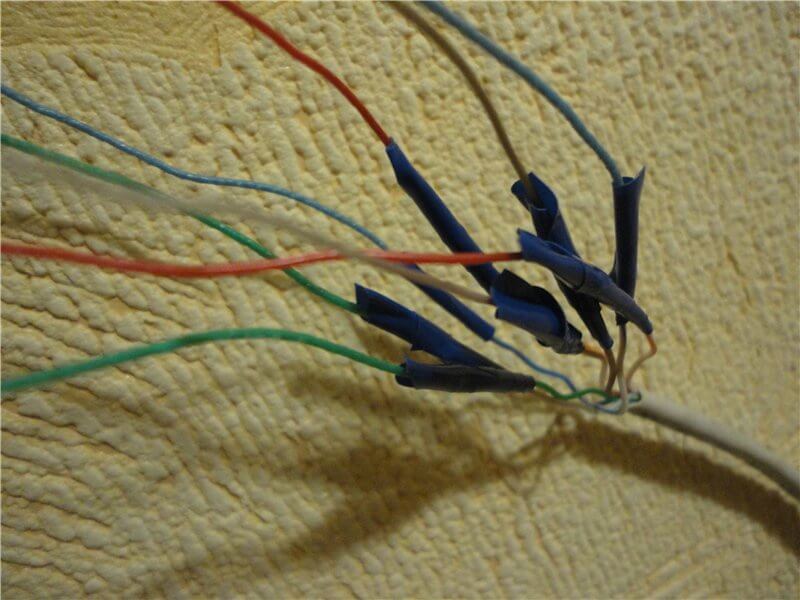

This happens if you need to extend the wire for a submersible well pump. All you need to do is to connect the fused wires through the terminal strip, and then insulate the extension point with shrink tubeas shown in the photo below. The submersible pump wire must be attached to the pipe and the cable so that there is no load on it, but additionally worry about the connection, make a small loop when installing it.

It is recommended to isolate the exposed area with a heat shrink tube even if there is a need to extend the wire in the bathroom or on the street in order to protect the wiring from high humidity.

Situation 3 - It is necessary to extend the cable to power a powerful electrical appliance in the apartment.

Another situation that needs to be taken seriously is the extension of the wire to connect powerful household appliances. For example, if you decideconnect oven, an air conditioner or an electric stove and at the input you have a broken copper conductor (its cross section must be at least 6 mm2), here the terminal block is not suitable, because current loads from the appliance will be significant. In this situation, it is recommended to increase the wire by soldering, and then carefully insulate the area with electrical tape. The same can be done by lengthening by crimping with sleeves or welding.

Situation 4 - The length of the wire of the temperature sensor of the system underfloor heating is not enough to connect to the thermostat.

In this case, it is recommended that you first read the instructions that came with the temperature controller, and if no restrictions are specified, feel free to usePVA wire You can lengthen the cable for the thermostat yourself, using all the same terminal blocks.

Situation 5 - It is necessary to increase the wire of the LED strip for hidden illumination of the ceiling or the tape itself.

No difficulties should arise in this situation. There are special connectors that allow you to lengthen the LED strip (photo below). The main thing is to take into account the requirements that we provided when we consideredRGB tape tips do it yourself. The wire to the tape is extended by any of the methods described above.

Situation 6 - Damaged twisted pair cable.

In this case, you can perform the extension of the plot with a new twisted pair using twisting or soldering. The main thing is to carefully isolate each extension point so that the bare veins do not touch each other. It is also convenient to do this with tape locks, by the way they are loved and often used by network installers.

That's all I wanted to tell you about how to build up a wire in a power outlet, under water and in other non-standard situations. We hope that now lengthening electric cables and wires will not cause you any difficulties when installing DIY wiring!

Also read: