How to make a twist of wires?

What is the danger of such a connection?

Twisting is the easiest and at the same time sophisticated way to connect wires. We note right away that in PUE 2.1.21 (Chapter 2.1) lists all allowed connection methods, and there are no twists among them. She is forbidden!

2.1.21. Connection, branching and termination of conductors of wires and cables shall be carried out by means of crimping, welding, soldering or clamping (screw, bolt, etc.) in accordance with applicable instructions approved in the established manner.

If during twisting you tighten the connected wires poorly, the contact will be poor, with a high transition resistance. Even if you tighten it well, the twist can weaken. Such contact will warm up. Moreover, the stronger, the greater the current will flow through it. The insulation will “float” from the heating, and because of this a short circuit will occur, with all the ensuing consequences - sparks, fire, electric shock!

It is not for nothing that the rules of the PUE are strictly forbidden to use this method in electrical work. Despite this, most electricians, and even experienced ones, use this method in everyday repair work.

If you apply twisting, it is only to check the operability of the circuits or the organization of very short-term lines, for example, during repair work to connect a power tool and other things. But in this case, it is better to use a variety of terminal blocks.

So, how to make a twist of wires? We’ll talk about this now!

detailed instructions

First, consider the simplest option, when it is necessary to fasten two single-core conductors of the same metal (for example, copper).

The technology is as follows:

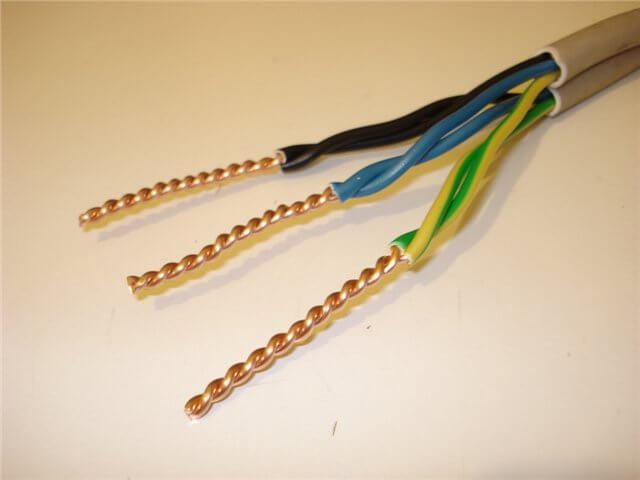

- Carefully strip both cores from insulation by about 5 cm. For this, you can also use a special stripping tool.

- Stripped bare wires to a metallic sheen with a knife or sandpaper.

- We cross two veins and twist them clockwise between each other so that they twist each other in a spiral (see diagram below).

- We isolate the finished twist using electrical tape. It is also recommended to use shrink tube, which reliably protects the exposed area from the external environment.

As you can see, there is nothing complicated.The peculiarity lies in the fact that it is necessary to expose the veins by at least 5 cm and twist with pliers so that there is an inextricable and reliable contact.

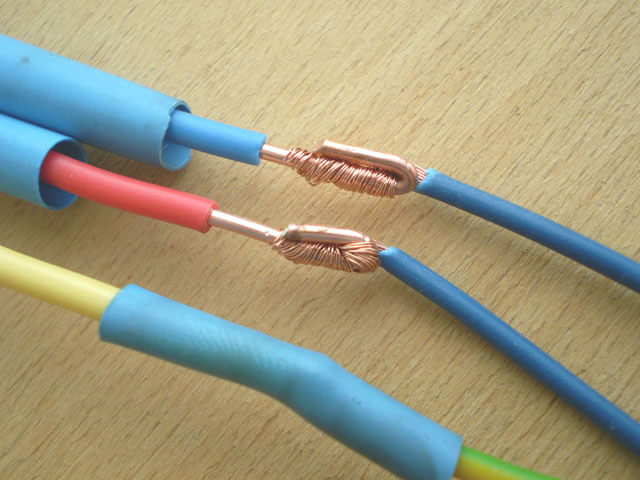

I would also like to give a couple of tips on a more difficult situation when it is necessary to twist a single-core and multi-core wire. In this case, we first repeat paragraph “1” and “2” from the instructions provided above. Next, you need to cross the products and the stranded wire carefully wound in the middle of the single-core (at a distance of 2.5 cm from the end). When all the turns are wound, the free end of the single-core conductor must be bent with pliers in the direction of the turns, as shown in the photo below. After this, the connection is insulated and placed in a junction box. By the way, in the same way you can make a good twist of two stranded wires.

You should pay attention to the fact that it is impossible to make twisting from aluminum and copper in any case.

The first and main reason is that galvanic vapor is formed between aluminum and copper, as a result of chemical reactions, when moisture enters (it will in any case), electrolysis begins and the compound breaks down. The contact resistance increases until it disappears completely, while it starts to warm up and burn. With direct current, such a connection is especially quickly destroyed.

The second reason is that copper and aluminum have different coefficients of thermal expansion, under load, when the contact heats up, the conductors will expand "differently", and after cooling, the twist will weaken and the resistance will increase even more - like a snowball.

The third reason is that an oxide protective film is always formed on the surface of aluminum, which also increases contact resistance, therefore, for connecting aluminum wires, they are coated with quartz-vaselin paste, and terminal blocks for them are sold already filled with this paste.

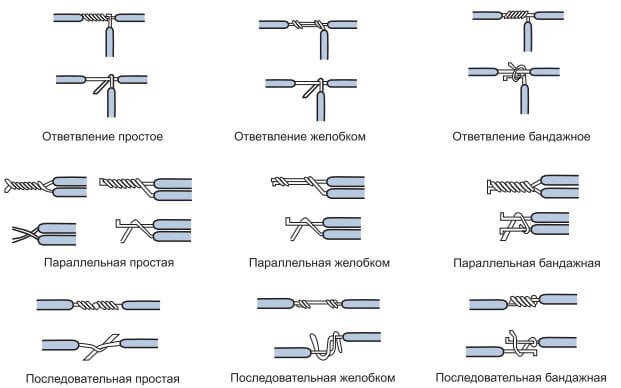

These are the schemes you can use when twisting the wires yourself:

We also recommend that you watch the visual video instruction:

An interesting fixture will allow you to quickly fasten:

Useful tips from professionals

Wire twisting as such is prohibited by the PUE, but if it is used in conjunction with other means, it does not contradict anything:

- Welding. If you simply attach two cores to each other and weld, you get a good one-piece contact. And if you also twist the wires before this, then the contact area will increase significantly, see the photo below.

- Soldering. The situation is the same as with twisting, only in soldering there is a main problem - solders, for example the widely used POS-60, do not provide mechanical strength. So if you solder two strands that are complex next to each other and insulate them and hide them in the distribution box, then such a connection will certainly work. But if the wire moves at least slightly in operation, the soldering will collapse. Therefore, always twist the cores if you choose soldering as a way to connect wires.

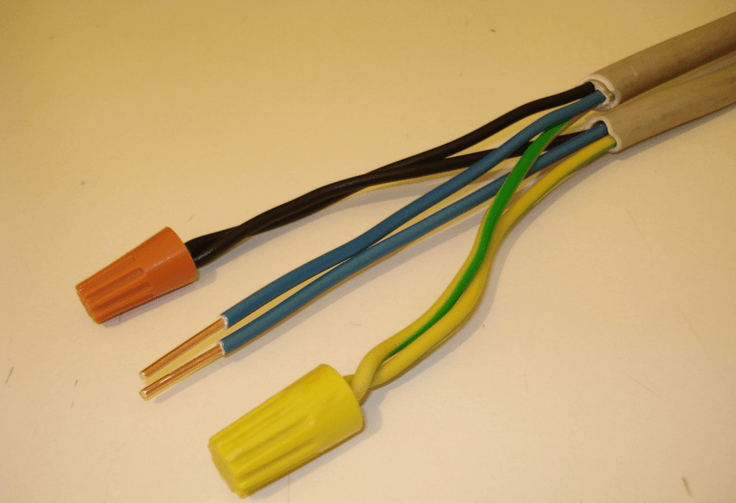

- Use PPE caps. To do this, you need to fold the connected cores together, insert them into the cap and start twisting the cap clockwise. The spring in it will clamp the veins and they will twist.

- Clamp the twisted cores with a screw terminal block (they are also called polyethylene terminal blocks).

It is important to note that none of the above options makes twisting waterproof, so if you decide to fasten the cores under the plaster in the wall, and without a box, be sure to insulate the connector cambricians.

That's all you need to know about how to do the twisting of wires yourself. We strongly recommend that you use more modern methods, and use twisting only when installing temporary wiring! In no case do twisting under tension, as today there is no such safe way. Any electrical work must be done with the lights off!

Related materials:

In the photo of the stranded and single-core wires, blue and red are connected, as I know, blue is zero working, and other colors (except yellow and yellow-green), including red - phase. maybe you don’t need to connect like that?

Hello Andrey! Well, firstly, in this article we are talking about how to twist the wires correctly, so the question of colors is a little not relevant. Well, and, secondly, if you already develop the topic of the correct connection lived by color, then, of course, the issue is debatable. If the color is not standard, you need to act on the logic. In this case, green is correctly connected with yellow, blue with blue, but what about the rest with the rest.

I need to wind 5 wires in 2 (i.e. connect 5 wires to the 2nd)

How to lengthen the street cable?

When replacing the poles, the copper cable from the house did not reach the line (SIP). You cannot completely replace it - it is underground. Electricians made twists and wrapped PVC tape with electrical tape, without protecting the connection in any way. Are there any standards on the basis of which you can require the electricity grid to do this properly?

Such an item is described in the PUE chapter 2.1 types of wire connections and insulation requirements.

Do I need a spike when lengthening the wires of ШВВП 2х0.75?

Never twist the wires using the methods outlined at the beginning of the article. Otherwise, you are guaranteed a minimum fire.

guys inappropriately by wagons to connect wires to sockets for God's sake, well, light okay.