How to conduct wiring in the house of aerated concrete?

Scheme selection

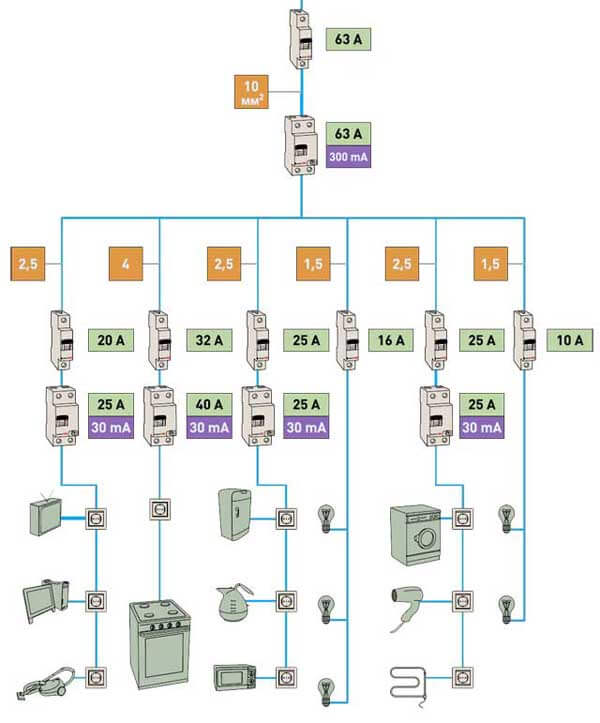

So, let's start by choosing a consumer connection scheme. The consumption of the wire for electrical wiring, the number of components, as well as the reliability and ease of operation of the installed wiring depend on it. Three main wiring diagrams in aerated concrete can be considered:

- all sockets and lighting devices are switched on through one automatic machine;

- all sockets are switched on through one circuit breaker, and lighting through another;

- all sockets of one room are connected through a separate machine, all lighting is through another (do not forget that the boiler, washing machine, electric heating, electric stove are switched on separately from other consumers).

The most suitable third option. The issue is considered in more detail in the article: how to divide the wiring into groups. The wiring diagram in a gas concrete house may look like this:

Next, you need to determine the type of wiring: hidden or open. In each case, its own specifics of work and a set of components for electrical installation.

Concealed wiring

Aerated concrete is easy to process material and for laying internal wiring, unlike concrete walls, does not cause special problems. It is easily cut both with a chamfer and with an ordinary “grinder”, only more dust. This stage can be done by yourself.

After that you need to dowall marking for electrical wiring, as well as the installation of sockets and switches for the entire site. One rule must be observed: the cable line is drawn only horizontally or vertically, turning up or down at an angle of 90 degrees. There should not be any diagonal wiring diagrams in the house.

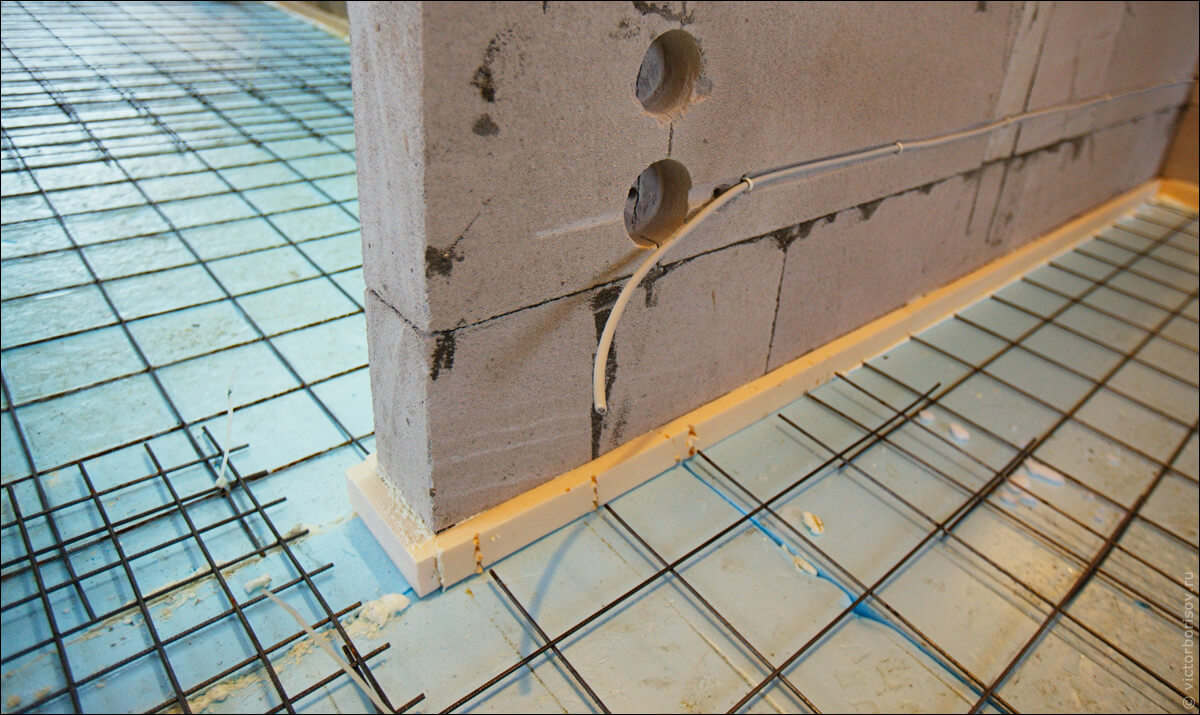

According to the scheme drawn up, an electrician creates strobes, cuts out seats for switches, sockets, sconces, wall lamps. In the prepared aerated concrete, it wraps up electrical components, lays wires, fastens them in the strobes with clamps, as shown in the photo below. After that, it fills the voids with a mortar, levels.

Some owners have a question, how to lay the cable in the wall using internal cable channels or electrical corrugation. In this case, you need to make the strobes deeper and wider (in the size of the corrugation). Usually they attach it to clips or dowels, clamps, which in some cases speeds up wiring.

However, do not assume that in this way you can replace the wiring in case of damage, without opening the wall. Pulling the cable out of the corrugation is difficult in most cases, and the wiring in the corrugation is not intended to provide interchangeable wiring, but is only a way to lay it and additional protection.

How to conduct electricity on the ceiling? If the walls in the house are made of aerated concrete, then the ceiling can be made:

- monolithic;

- reinforced concrete floors installed;

- mounted wooden floors.

Depending on the type of interior flooring, you need to choose a method, how to make a wire connection to chandeliers, ceiling lights. If the ceiling is monolithic, then in its manufacture should have provided channels for wiring. In this case, it is enough to use a ready-made solution. In the case of prefabricated reinforced concrete floors, technological holes that are provided in advance can be used. If these are wooden floors, then it is necessary conduct open installation with the fulfillment of all requirements of the PUE. About, how to conduct wiring in a wooden house, we told in a separate article.

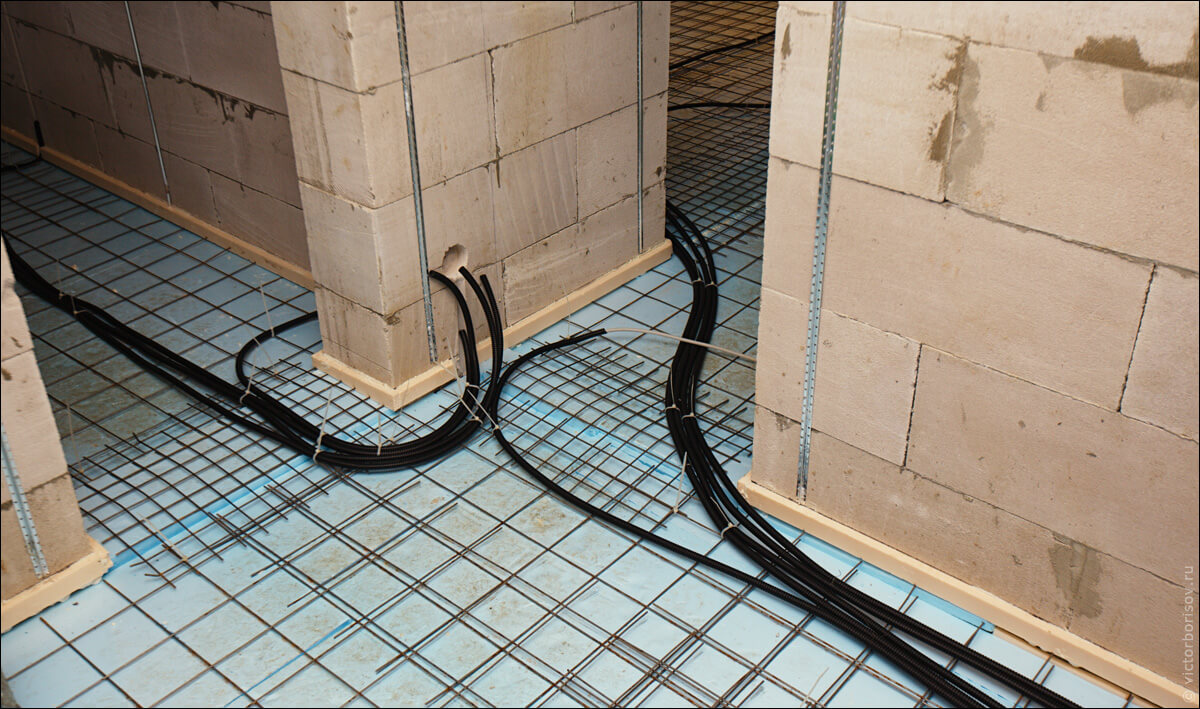

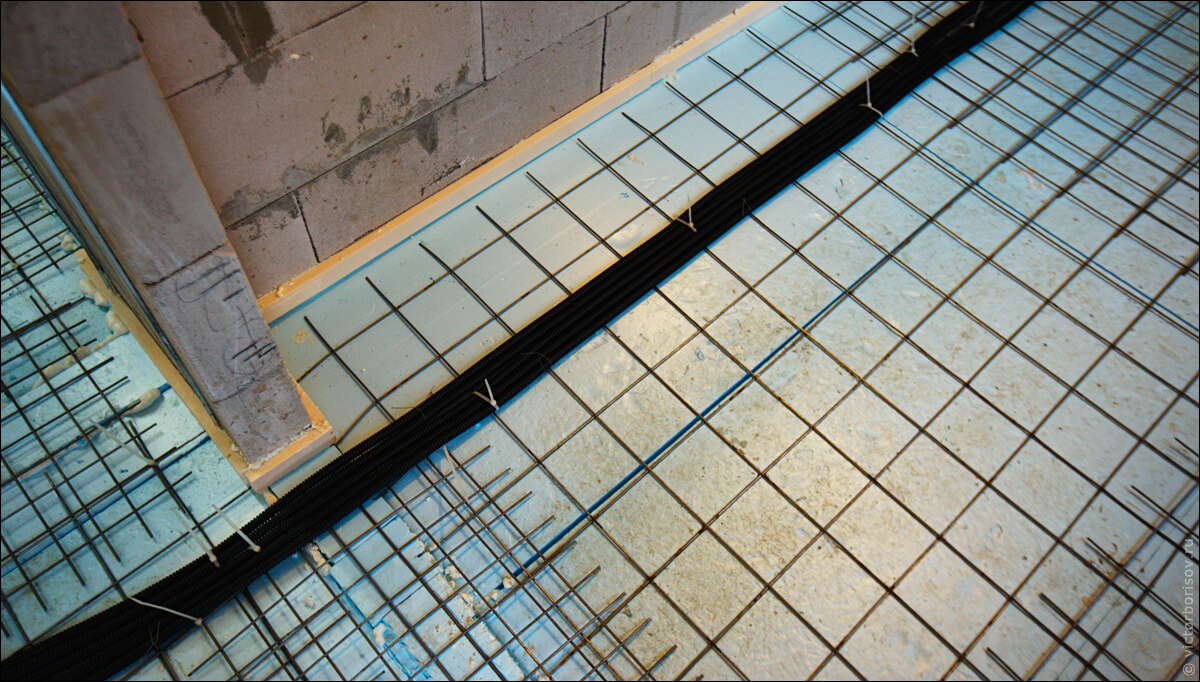

The photo below shows another popular option for wiring an electrician in an aerated concrete house - by floor:

In this case, the cable must be additionally protected with black corrugation (it is more durable). About, how to lay on the floor, we also talked separately.

Outdoor wiring

Laying an open electrical wiring in a house made of aerated concrete is carried out in case of time limitations and unwillingness to dust. This type of work is much simpler and can be used for both gas block and wooden walls, as required PUE. All components are purchased for open wiring, the wires must be designed for maximum rated load and have double insulation from flame-resistant material. All sockets, switches, junction boxes are installed on the surface of the wall and fasten them. Under them, gaskets made of asbestos, metal or other non-combustible material. Although modern products are made of non-combustible or non-combustible materials and require installation without gaskets (pay attention to instructions or consult a specialist).

We recommend choosing VVGNG-LS cable, it is non-combustible. All wiring and installation is similar to installing hidden electrical wiring in aerated concrete, except that the wire is laid on the surface of the wall in the plinth, grooves, corrugation, or on dielectric insulators.

The connection of the conductors is performed usingterminal blockswelding, soldering or crimping. Twisting is not allowed (Chapter 2.1. PUE Sec. 2.1.21).

The installation of wiring in the house from the gas block must be carried out by specially trained personnel - an electrician, in order to avoid possible malfunctions during operation. In the video examples below, all the stages of laying an electrician in an aerated concrete house are available:

That's all I wanted to tell you about this issue. We hope you now know how to conduct electrical wiring in the house from aerated concrete with your own hands!

It will be interesting to read: