What are the cambrics for wires and why are they needed

What is cambric used for in electrics?

The main task is to insulate the electric cables, but the people came up with a lot of other applications, from the role of covers for screwdrivers and awls, to use in fishing tackle. Twisted cable connections (PUE is already forbidden), by soldering, welding, bolt, sleeves, as well as wires terminated with terminal lugs, must be insulated. Most of these compounds can be worn with cambric. For additional fixation and protection against moisture, the edges are fixed with electrical tape, and if one of the edges is free, it is heated by a lighter and squeezed with pliers.

In addition to insulating the joints, you can restore the insulating layer of the wire using cambric, fixing its edges with electrical tape so that it does not move. This type of insulation is suitable for DC and AC circuits up to 1000 V.

An additional function is marking. On a light cambric, a black felt-tip pen or marker is perfectly visible. In any circuits, both power and signal, and communication lines at the ends of the cable near the terminal put on a cambric with the designation wire marking.

Cambrices come in different sizes, pick up products a couple of millimeters larger than the diameter of the cable, otherwise it will constantly fall off or not fit. If you try to stretch to the desired diameter, it may burst, because there is almost no stock in size for this product. This lack heat shrink tubing. In addition, PVC pipes dry out and crack when heated, and harden very hard during frost.

Shrink cambrices - shrink when heated

The heat shrink tube or cambric, although it performs the same tasks, differs from the usual one both in the method of application and in the material from which it is made. Usually it is polyethylene and other polymers.

Shrinkage during heating can be reduced by half. This advantage allows you to use the same tube size for a much larger range of wire cross-sections. This gives a definite plus when used as insulation for all kinds of terminals and connections, because the shape of the terminal block does not affect the quality of the covering. The heat shrink will compress and repeat any contours.

Shrinkage stretches well, up to 1.5-2 times from the original, but this must be done carefully, following the integrity of the surface.So you can stretch the heat shrink on the wires and terminals, if there is not the right size

The next difference from PVC tubes in heat shrinkage is in appearance - they are sold in any color, including fully transparent or with color. This opens up even more convenience for labeling, for example, break the wires of one group by colors and sign by contacts. Like ordinary cambrices, these products are inexpensive, but they can be found in every store of electrical or household goods.

How to use Cambrian

In the ideal case, you need to sit down with a stream of hot air. Any building hair dryer is suitable for this. But more often it happens that it is not at hand or there is nothing to connect to.

The second option is a soldering iron. Walk through the surface of the tube with the casing of the heating element and it will sit. The sting does not need to do this for three reasons:

- Too high a temperature can melt cambric.

- Traces of soot remain from the sting.

- In order not to spoil the sting.

The third option is to use fire sources. It can be matches or a lighter. Keep the flame a couple of centimeters away from heat shrinkage so as not to damage it, walk with quick and short movements on all sides to achieve uniform contraction of the insulating layer. For a quick effect, you can do this directly with a flame, then the movements should be even faster, and you should be more careful. The disadvantage of this method is that traces of burning can remain on the cambric. Turbo lighters do not have this drawback, but the flame temperature is very high and it is easy to burn the pipe, so keep the flame away so that only hot air flows into it.

The video example demonstrates how to use cambrics for wires:

Heat-resistant insulation - what is it

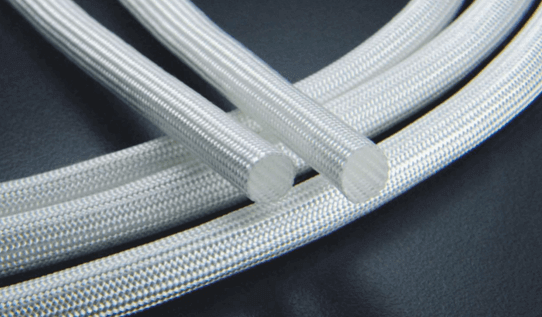

Fiberglass tubes are a kind of cambric, resistant to high temperature, tolerate from -60 to 510 degrees without any problems. Fiberglass is impregnated with varnishes to improve electrical insulating properties. Such options are often found in electric kettles, heaters, electric stoves and similar appliances. They are put on supply wires and wires of internal connections near TENOV and spirals. Heat-resistant cambrices for wires protect contacts from temperature, thereby reducing the likelihood of corrosion and weakening, as well as melting of insulation. They cost more than the rest, so the application everywhere does not make sense.

Alternative use.Home-made and radio enthusiasts use heat-resistant fiberglass tubes for insulation homemade soldering iron, burners and similar appliances. For example, put on a sting under a spiral so that there are no interturn closures. In the process, the varnish burns, after which it continues to carry out its tasks and does not burn out.

Wire cages are in some cases better suited for insulating conductors and joints than insulating tape. Their price and ease of use allows to increase the quality, safety and durability of electrical devices and circuits. Of course, this is an integral consumable for an electrician, it also looks more aesthetic than electrical tape, and more reliable in some cases, but it is better to use a pair of both.

Finally, we recommend watching a video that shows how Cambrices are used to mark wires:

It will be useful to read: