Which is better to choose: hammer drill or hammer drill

Hammer drill

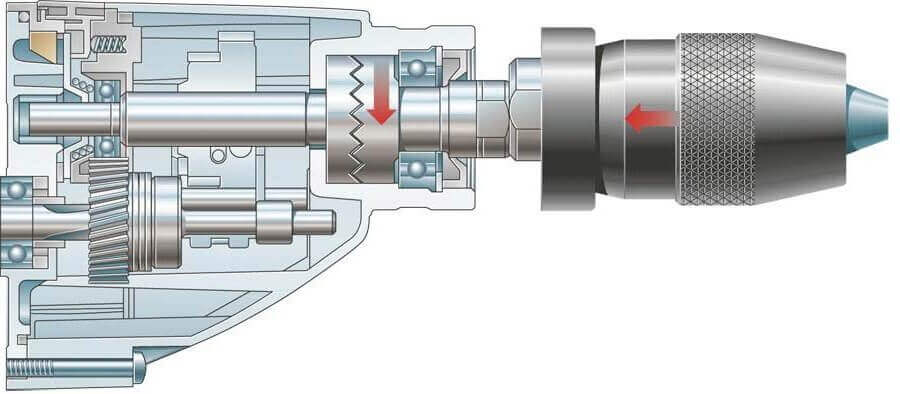

It differs from the usual built-in mechanism for translational movement - strikes. Their cartridges are similar in design, look and are arranged the same. For holding working equipment, drills, for example, three-jaw chucks are used. This design during rotation of the outer holder of the cartridge shifts the cams to each other, with the help of which the clamp of the drill is provided.

The image below shows the internal structure of the instrument:

There are two modes for working:

- Drilling

- Drilling with a punch.

The impact mechanism is implemented using ratchet from a movable and non-movable ring with teeth on one side. This mechanism does not involve longitudinal movement over a large length - the amplitude of the drill movement is within a couple of millimeters, and its energy depends on the force of pressing the hammer drill against the wall and is within the units of Joules (J). That is, it rather does not hit, but vibrates into the processed material.

Hammer drill

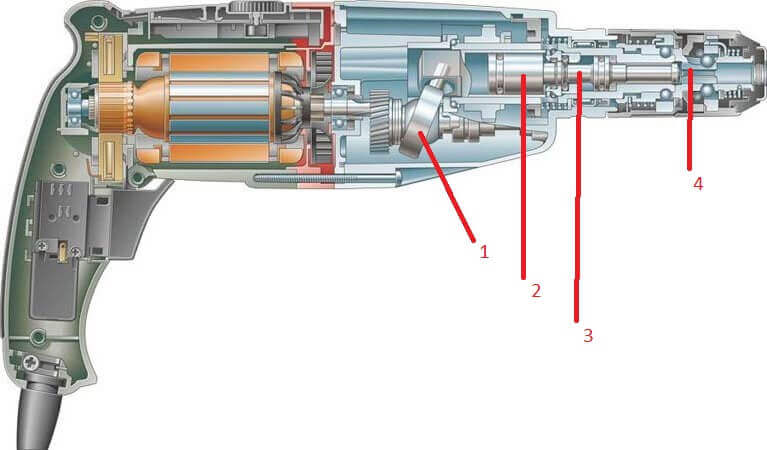

The main difference between a punch and a percussion drill is the design of the percussion mechanism. It can be electromechanical and electro-pneumatic. The latter is found in most models of the modern market.

The principle of operation is as follows: the electric motor drives the gear of the gearbox, on the output shaft of which is swinging or, as it is also called, a drunk bearing (1). It drives the piston along the cylinder. As a result, the piston interacts with the ram (2), which hits the hammer (3), transferring energy to the equipment installed in the SDS cartridge (4). Thus, greater energy and depth of impact are achieved.

Interesting: at the same power, the impact energy of a hammer drill is 2 or more times higher than the impact energy of a percussion drill, which is more suitable for concrete.

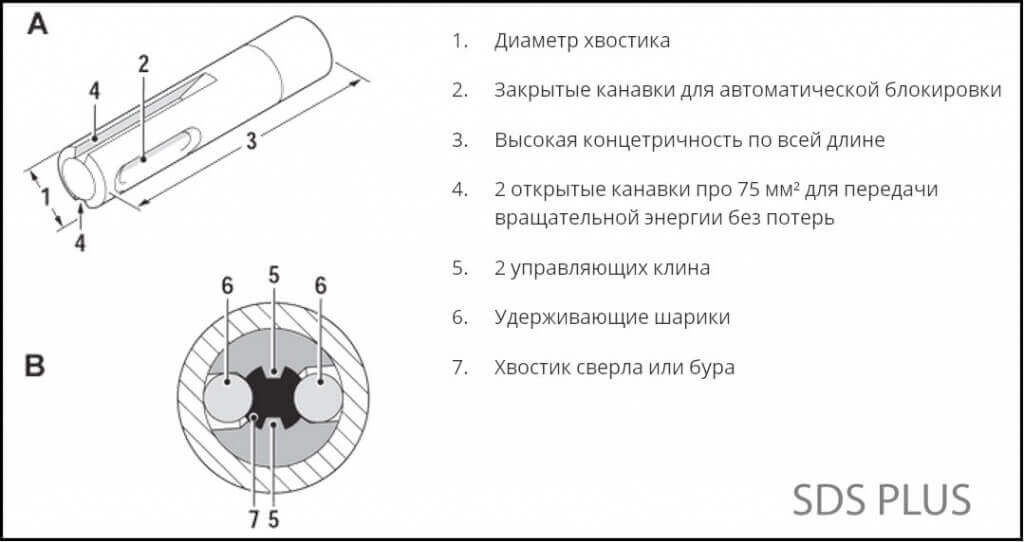

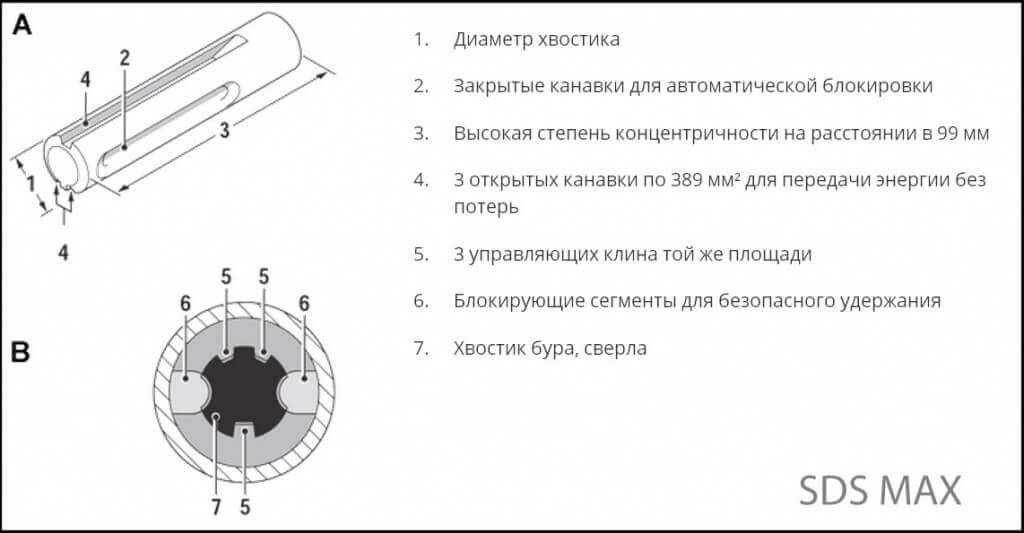

The second difference between a punch and a drill with a percussion mechanism is the method of fastening the drills in the cartridge. If in the previous embodiment, cam clamping chucks were used, then SDS chucks are used here. It is impossible to install an ordinary drill in them - only special drills with an appropriate shank. It should have 4 slots which in pairs have different diameters, they are needed to hold the snap.

To install conventional drills in the SDS chuck, you can install the adapter on the cam chuck, but in this case it will not be possible to achieve high quality drilling due to beats.

It is also worth noting that there are shanks and cartridges of two types:

- Under 4 slots - SDS-plus, holds equipment with a diameter of up to 26 mm.

- Under 5 slots - SDS-max, drills with a diameter of more than 20 mm.

What is the difference

To summarize, to understand that a hammer drill or hammer drill is better, compare the general characteristics. We take for the condition that the power is the same. Then, the speed of the puncher will be about 800-1000 rpm, and the drill 2500-3000 rpm, the torque differs similarly.

Typical impact energy depending on the model within:

- Impact drill - small, determined by the pressure against the wall. Small and the amplitude of the longitudinal movement of the drill.

- Rotary hammer - 0.5-27 J.

Equipment:

- Impact drill - for crowns and drills of various configurations with a cylindrical shank.

- Hammer drill - drills, chisels, crowns with a shank type SDS. When installing the adapter on the cam cartridge, it is possible to install any equipment from drills and screwdrivers.

Operating modes:

- Impact drill - drilling without impact and drilling with impact.

- Hammer drill - drilling, drilling with impact, only impacts.

The cost of devices of the same power at the time of writing:

- The cheapest hammer drill at Yandex.Market is 800, 400 watts.

- The cheapest rotary hammer is 1839, 400 watts, 1.5 joules.

What is better to buy and where to apply

We examined the general structure of these tools; now we will move on to work in everyday life. For example, we have compiled a selection of tasks that are encountered by an electrician and an ordinary builder.

- Installing Sockets and junction boxes. This procedure is performed using a crown. Various crowns are used for wood, brick and concrete. For concrete, snap-in equipment with victorious solders or with a diamond coating is used. It is carried out without a blow, so both a conventional drill and a hammer drill or perforator will do.

- Drilling through holes in solid materials. When drilling concrete and brick, a blow is needed, both versions of the tool are suitable, but for punching - only a punch.

- Strobing - performed by a puncher with a chisel or chisel cutter. The hammer drill in this case is included in the “only hits” mode.

- Chiselling of niches under the guards - only a punch.

If you look at a number of tasks that solve both of these tools, you can come to the conclusion that it is better to take both. For a house, to drill a hole in the wall a couple of times a year and hang a picture, for example, you should choose a good impact drill than a bad puncher. For repairs on a tight budget, a rock drill will be a more versatile solution. Discussing the topic “what is better ...” is not entirely objective, because these are different tools, although they are used for similar tasks.

Finally, we recommend watching a video that explains in detail and clearly what to prefer in different conditions:

We hope that the material provided has helped you decide what suits you best: an impact drill or a hammer drill. If you have questions, ask them in the comments under the article!

Related materials: