What are the solders for soldering: types, brands, purpose

To create a tight, reliable connection of metal parts, soldering is most often used. The essence of the process is the bonding of materials when heated with an alloy - solder, the melting point of which is lower than the melting temperature of the substances to be joined. When heated, the solder, spreading between the connected areas, provides strong adhesion (adhesion) of metals to each other at the molecular level, which gives high strength and electrical conductivity of the compound. The molten solder should wet the metal well. That is, the connection between the molecules of a solid and a liquid should be more reliable than between the particles of a liquid material. In this article we will tell the readers of the site Elecroexpertwhat types of solders for soldering are, having considered the purpose and scope of each of the brands.

Solder selection

In order for the connection to be of high quality, it is necessary to choose the right solder. To do this, consider:

- types of metals or alloys to be joined;

- soldering method;

- temperature limits;

- the size of the connected parts;

- required mechanical strength;

- corrosion resistance.

Varieties

The types of alloys intended for the soldering process, depending on the melting temperature, are divided into hard refractory and soft low-melting compositions. The former melt at 450 degrees and above, the latter below this value. Carbide brazing is more durable. But soft types of solders are indispensable for radio installation work.

Soft or fusible

The most widely used are tin-lead solders, the abbreviated name is PIC. The number indicated in the marking after the letter reduction corresponds to the percentage of tin. For example, POS-60 contains 60% tin. These types are used in the manufacture of devices, electronic devices.

POS-90 contains only 10% of toxic lead; therefore, this variety is used for the repair of food utensils and medical instruments.

POS-40 is used for brazing brass and copper pipes, electrical equipment, elements made of galvanized iron.

POS-30 is used for soldering zinc sheets, in the cable industry, for soldering galvanized iron.

POS-61 is used for soldering radio components to printed circuit boards. Its melting temperature is 183 degrees, and a complete transition to a liquid state occurs at 190 degrees, which helps to avoid overheating, and prevents the failure of radioelements.

There is a universal and convenient version of POS-61, which is a hollow tin-lead tube with rosin inside. This form is very convenient, since the soldering is carried out without additional supply of flux.

The next type of PIC is POSSu brand solder. In it, in addition to the lead and tin component, up to 2% of antimony is present.This material can solder the windings of electrical machines, electrical components, cable products, galvanized parts.

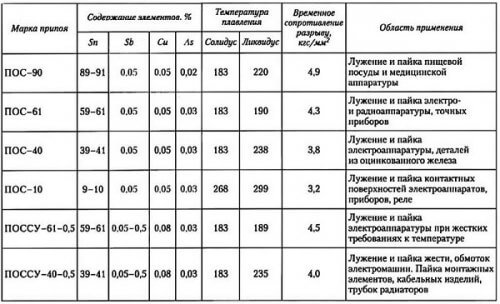

The table briefly presents some types of PIC and their main properties.

Currently, lead-free alloys are widely used in the manufacture of electronics. For example, POSu95-5 lead-free solder. The determination of its composition is possible by marking. The number 95 means the percentage of tin, 5 - antimony. The melting point is in the range 234 - 240 degrees.

Solid or refractory

Hard solders for soldering create high bond strength. The disadvantage of their use is the need for intense heating above 500 degrees, which can damage some types of devices.

Among refractory with a high melting point, two groups are divided: copper and silver alloys. Copper solders based on zinc and copper are used in compounds intended for static loading due to fragility. They can not solder materials subjected to dynamic - shock or vibration load.

Silver types of solders are universal, they can solder various materials. The disadvantage is the high cost, so the use of the composition should be economically justified. A silver alloy is used for soldering stainless steel, copper, in prosthetic dentistry, and for repairing silver jewelry.

Compositions containing silver are indicated by the letters PSR. There are markings PSr-15, PSr-25, PSr-45, PSr-65, PSr-70, where the number indicates the percentage of silver.

Low temperature

The composition of POSK 50-18 includes 50% tin, 18% cadmium, 32% lead. Cadmium enhances corrosion resistance, but makes the material toxic. The purpose of the solder is the installation of components that are sensitive to overheating. The melting point of the material is 142-145 degrees.

The melting point of the ROSE alloy ranges from 90 to 94 degrees. This species is marked as POSV-50. The composition contains 25% tin, 25% lead, bismuth - 50%. The percentage of metals may vary slightly. Material is produced in the form of rods, granules, ingots.

The composition is used in jewelry production, for the installation of electronic devices, tinning of copper tracks on printed circuit boards. It is used in electromechanics for protective fuses, fuse-links. As well as for the dismantling of electronic components and connectors with plastic cases

Benefits of ROSE:

- emits a minimal amount of toxic substances, since it does not contain cadmium;

- easy to melt, enough contact with boiling water;

- can be used at home without the use of special equipment;

- economical to use.

The melting point of the WOODA alloy is in the range of 65-72 degrees, which expands the scope of its application. But 10% of the cadmium in its composition makes the material toxic. The remaining components of the alloy: 13% tin, 27% lead, 50% bismuth.

It applies:

- in sensors of fire alarm systems;

- in microcircuits;

- in electroforming;

- in dentistry;

- for the manufacture of cast elements;

- in the printing business for the manufacture of fonts, matrices, cliches;

- in mechanical engineering and shipbuilding;

- in the aviation industry;

- in the metallurgical industry.

Other species

There are rare solders used for special conditions. These include:

- nickel-based formulations used in parts operating under high temperature conditions;

- gold used for vacuum tubes;

- magnesium used in ferrous and non-ferrous metallurgy.

Let us give examples of some of them, since there are a lot of them and it is not possible to consider all types within the article.

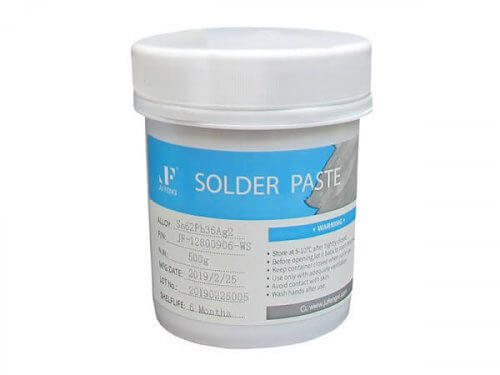

Solder paste

Soldering microcircuits, mounting SMD components on printed circuit boards, complex repair of mobile phones can be carried out using solder paste, consisting of non-wash flux and Sn62Pb36Ag2 alloy. The composition contains 62% tin, 36% lead and 2% silver.

The paste meets the basic requirements for surface mount technology (SMD components) in the electronics industry.

For aluminum

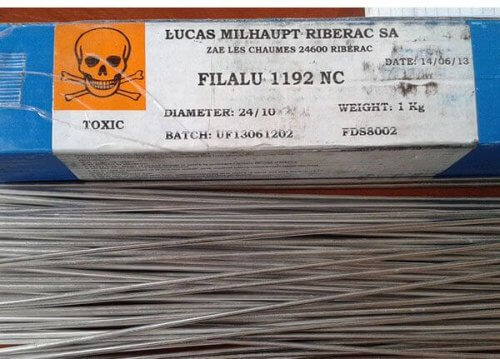

Lucas-Milhaupt Filalu 1192 NC solder has good fluidity, high adhesion to aluminum. They can solder refrigeration equipment, car radiators, air conditioners. Soldering aluminum with aluminum will not cause difficulties even for non-professionals. Available in the form of a bar with a flux inside. Melting point 577 degrees.

Composition structure: Si-11.94%, Fe-0.18%, Cu-0.01%, Mn-0.03%, Mg <0.01%, Zn-0.01%, Al-rest, FLUX - 32%

For copper

For soldering copper, practically any kind, both soft and hard, is suitable. For example, solders made of tin, lead, zinc, silver can be used.

Total

A great variety of solders for soldering various products are produced, it is simply not realistic to list them in the volumes of one article. But summing up the above, we note:

- For the installation of electronic components, radio amateurs use a relatively fusible POS-61, parts on lead-free solder are soldered by preliminary tinning with ROSE alloy to reduce the melting temperature, and subsequently the parts are easily dismantled. For pipes and refrigeration equipment use solid fusible grades.

- The composition of the alloy should not contain toxic substances in excess of the established norm. Work should only be carried out in a well-ventilated area, observing safety measures.

Related materials:

- How to solder radio components from boards

- How to choose a soldering iron for soldering wires

- How to solder wires