What is better to choose: a PVA wire or a ShVVP cord?

Feature Comparison

To understand the difference between a ball screw cable and a PVA wire, let's compare the technical specifications.

| Ball screw

(W-cord, B-sheath PVC, B-outer PVC sheath, P-flat) |

PVA

(P-wire, PVC B-sheath, C-junction) |

|

| Rated voltage, Volt of alternating current of 50 Hz | 400 | 660 |

| Section range, sq. mm | from 0.35 to 4 | from 0.75 to 16 (sometimes 0.5 and 25 sq. mm are found) |

| Number of cores | 2 or 3 | from 2 to 5 |

| Permissible operating temperatures, degrees Celsius | from -25 to +50 | from -50 to +50 |

| Service life, years | 6 | 6 |

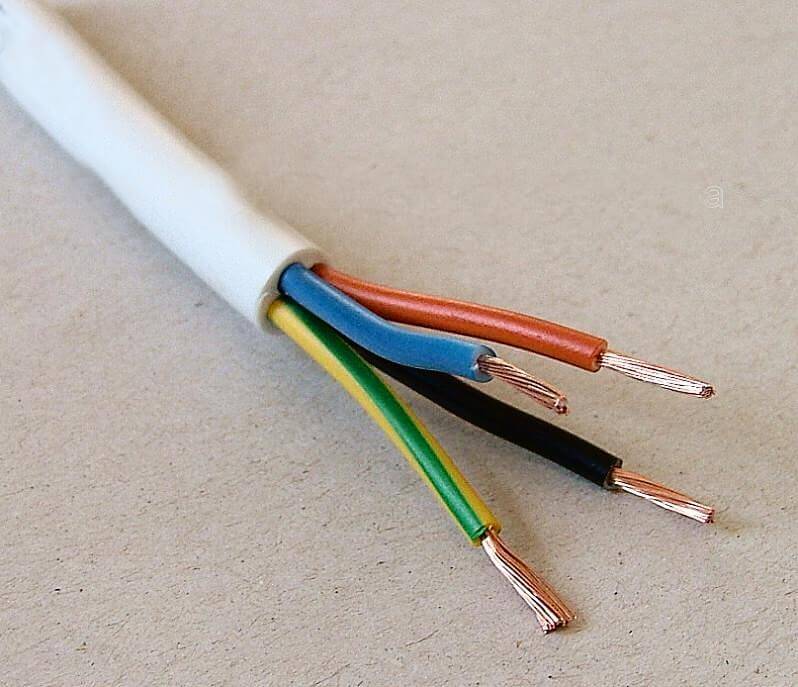

The insulation of both PVC plastic conductors, both the outer sheath and the sheath of each core. Both cord and wire are used to connect mobile equipment. But their design is distinguished by the fact that for the ball screw, the cores are laid parallel to each other, and the outer shell is made of a thin layer of insulation. Because of this, the cord has a flat shape, as indicated in the marking.

The wires of the PVA wire are already twisted together along the entire length, the outer sheath is completely filled between the core space, which gives a thick protective layer. However, twisted laying of cores increases the consumption of conductors and other materials per meter of cable, and a thick outer sheath increases the consumption of PVC - all this leads to an increase in the final cost of the product.

Attention: the cost of PVA is greater than that of ball screws by about 30%.

If you carefully study the table, you will notice that the cross-sectional range of the cord in question is concentrated in smaller quantities than the wire. This difference suggests that the ball screw is designed to power consumers of lower power. The difference in design also leads to the fact that a flat cord is easier to bend and takes up less space when laying, but is more susceptible to accidental damage than a thick round and twisted PVA.

Application area

Extension cords or carrying

The main scope and purpose of the discussed conductors is extension cords. In this case, if the extension cord will be used in harsh conditions (at a construction site, in the garage for connecting a power tool), it is better to choose PVA wire. In this case, frequent excesses and occasional bumps and friction are characteristic, therefore it is important that the conductor has high-quality and thick insulation.

If the extension cord is laid somewhere behind furniture or in another way, where the likelihood that it will be crushed or other damage will occur is minimal, then it is quite possible to choose ShVVP cord. It will be more convenient to lay or hold in narrow places due to the smaller size. Such extension cords are used when the outlet is located in an inconvenient place, as well as for connecting several electrical appliances installed in one place, for example, a TV, media player and speaker system.

Let's talk about what is best for an extension cord: a PVA wire or a ball screw. Generally speaking, a PVA extension cord is used where frequent bumps or damage are likely. It is also better suited for connecting powerful electrical equipment, such as rotary hammers, grinders, or even some technological devices such as heat guns, provided there is no direct hit of hot air streams or parts of the device on the wire itself.

ShVVP use for those extenders in which powerful devices are not connected. They are better suited for connecting small kitchen equipment, fixtures, electric shavers and consumer electronics.

About, how to make a do-it-yourself extension cord, we told in the article. Check out the material to make a reliable extension cord for connecting household appliances.

Lighting and wiring

Since the hidden and open wiring are stationary electrical installations, then neither the wire nor the cord is suitable for this definition. In contrast, cable with single-wire conductors of the type VVGng Specially designed for use in wiring. Nevertheless, the question often arises: “Is it possible to use ballscrew or PVA for wiring or lighting?”. For main wiring and connecting outlet groups, their use is not recommended.

For ball screws, the outer shell is thin enough for laying in the wall, although this can be fixed by laying it in a PVC corrugation. At the same time, although PVA has a thick insulation layer, there is an interesting opinion that this will make it difficult to transfer heat to the environment with conductive conductors, which is especially important for hidden installation under plaster.

At connecting spotlights in a suspended ceiling, wires are laid behind a plasterboard, and if the ceiling is suspended, then on the surface of the draft ceiling. Due to the variety of design solutions for installing lighting points along curved contours, it will be more convenient to use wires with flexible conductors. In these cases, it will be convenient to choose a ball screw or PVA. But in terms of durability and mechanical strength, in this case, PVA is better suited.

Outdoor installation is only permitted in Pvc corrugation, and the operating temperature range is better suited for this purpose with the PVA wire.

Finally, we recommend watching a useful video on the topic of the article:

We examined the differences between ball screw and PVA and tips on which one to choose for specific tasks. But we want to remind you that the connection of these wires must be carried out using terminal blocks with a spring clip (type VAGO), soldering, welding, sleeve. It is strictly forbidden to twist, and when clamping under a screw (as in sockets), the wires of the wire begin to break, due to which contact deteriorates. Over time, it will bask or even burn out.

Related materials: