What are the brushes for electric motors and how are they marked

It is difficult to imagine the life of a modern person without the use of electric machines. They have firmly entered our lives, these are devices that help in the household and in the kitchen - combines, meat grinders, etc., and workshops use screwdrivers, drills, and other power tools. In household and industrial appliances often used collector motor. During its operation, the brush-collector assembly is worn out. To repair this unit, you need to understand the labeling of electric motor brushes, which we will discuss in this article.

Purpose of the brush assembly

The brush-collector unit is designed to transmit electricity to the windings of a rotating armature. In it, brushes act as a moving sliding contact, which wear out due to high friction and high revolutions of the electric motor. Therefore, the material from which they are made, are subject to special requirements. It is selected in such a way that there is no overheating at the point of contact.

Electric brushes are used not only on collector engines, but also on synchronous machines and induction motors with a phase rotor, where instead of a collector copper rings are installed.

They must provide:

- Reliable connection to collector lamellas or rings, with sparking and the risk of windings being shorted to a minimum.

- The smallest resistance at the sliding contact point.

- Resistance to friction. The wear resistance of the material should ensure operability for a long time.

Classification and labeling

The industry produces various types of electric brushes. They are divided by operating conditions:

- Carbon-graphite, have low strength, are used in devices with a small mechanical load. Marking G21, G22 is applied.

- Graphite. They are made of graphite with filler from soot or other substances. They provide switching of small currents in generators and motors. Used marking G20, EG61A. The Korean company has mastered and patented graphite brushes with the designation KPNG, which have an increased service life, which increases the reliability of the equipment and increases the overhaul period.

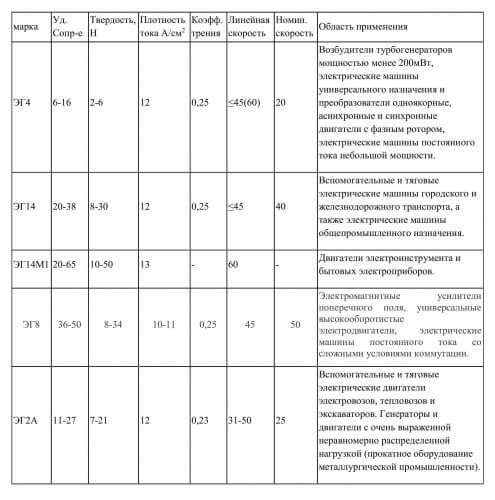

- Electrographic - have increased mechanical strength. In the manufacture of the material is saturated with carbon. Provide switching currents of large magnitude. The brands EG, EG74, EG2A, EG14, EG841, etc. are produced.

- Copper-graphite (metal-graphite). The brushes include a filler made of copper, silver, tin and graphite powder. They have great strength, resistant to gas and liquid media. They are used for switching in medium and high complexity. The markings MG, MGS, MGS, MGS20, MGS51, MGSO, MGSO1M, M1A, M1 are used.

What are the criteria for choosing brushes

Based on the current GOST 12232-89, according to which the industry produces brushes installed in an electric motor, you can choose the necessary product.

To choose them correctly, you need to know the parameters:

- The material from which the contact is made (brand of brush).

- Sizes: depth, width, length. Moreover, the length may have slight differences in the direction of increase or decrease.

- Part performance (configuration or type). The performance is determined - with or without a conductor, where it should be attached, what material it is made of and what the ferrule should be for connection (ring or “plug”, etc.).

This information is presented in the respective manuals for engines or the marking of their components. Below, as a sample, only a small part of the table is presented. According to this information, graphite brushes are selected in size and output conductors.

Labeling Explanation

Domestic marking of brushes for electric motors includes complete information about the product, for example:

EG-14 20 * 32 * 40 K1-3

The decoding of the brush markings will look like this:

- EG-14 - the material from which the brush is made;

- 20 * 32 * 40 - sizes;

- K1-3 - configuration (determined by the table).

At the same time, there is additional information in the directories, where parameters for each type of brush are indicated.

According to the information on the purpose and size in the reference books, you can pick up brushes for power tools in which a commutator motor is used. It should be borne in mind that their markings are different.

For a puncher, drill, mixer and grinder, there can be either the same or different brands of brushes, since these devices have different loads and revolutions. This must be taken into account when replacing, and not choose only in size.

If the engine has design features, you can specify the required parameters when ordering:

- The number of current-carrying conductors, as well as their length and cross section.

- Connection pin and pad configuration.

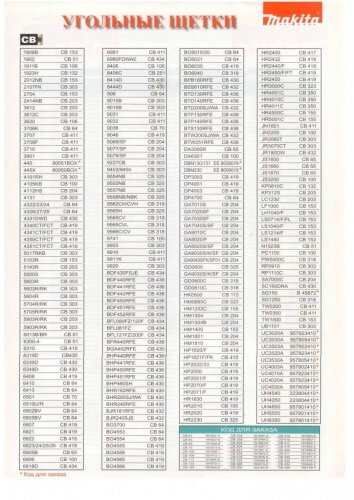

Often, manufacturers of power tools provide a table of brands or catalog numbers that display information on which appliance which brush is suitable. The table below shows the conformity table for Makita power tools, which indicate the type of tool and the marking of the installed brushes.

The following two tables will help you choose components for Bosch power tools. The upper column shows the types of brushes marked by numbers (# 1, # 2, # 3 ... # 15) and their catalog numbers, vertical columns indicate the model of the power tool and also their numbers.

The following two tables will help you choose components for Bosch power tools. The upper column shows the types of brushes marked by numbers (# 1, # 2, # 3 ... # 15) and their catalog numbers, vertical columns indicate the model of the power tool and also their numbers.

When selecting, you need to have an idea of what the difference between coal and graphite and other types of electric brushes consists of. Incorrectly selected components can lead to the failure of the collector, and the motor will quickly become worthless or simply newly installed parts will quickly disappear.

Now you know what marking of motor brushes exists and how to choose suitable electric brushes for the right tool. We hope the information provided was useful and interesting for you!

Related materials: