How to connect SIP with a copper cable - the main ways

What is important to know

A typical situation where a SIP connection with a copper cable may be required arises when a private house or summer cottage is connected to a power line made by a self-supporting insulated wire. Here, first of all, Technical Specifications Receivedissued by the energy supplying organization. This document usually contains detailed information on how and by which conductor the power circuits to the meter should be made. It can also be indicated how to connect the wires. As a rule, the requirement is that the conductor from the overhead line to the metering board is visible and solid.

Connection options

Depending on the location of the metering board, options arise to connect the self-supporting insulated wire to each other or to another type of wire. Next, we will consider in what situations and how exactly it is necessary to connect a self-supporting insulated wire with other conductors.

The metering board is located on the line support

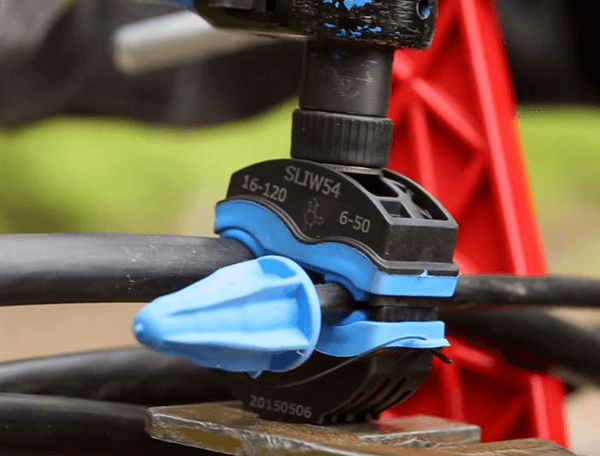

The line is connected to the metering board with a solid conductor, which in the shield is connected directly to the input automatic machine. To connect the conductor to the line, you should use the standard piercing clamp, specially designed for SIP lines. An embodiment of such a connector is shown in the photo below.Piercing clamp it is intended for connection of solders to the main lines. This instance can connect a line with a cross section of 16 mm2 up to 120 mm2 with a tap having a cross section of 6 mm or more2 up to 50 mm2. As a solder, SIP can be used, or an ordinary copper cable, for example VVG.

The main elements of the compression are two steel plates with pointed teeth, which, when tightening the mounting bolt, come together and piercing the insulation of the linear and solder wires, ensure reliable contact and tightness of the fastening place. The bolt is tightened to failure, designed for a certain compression force. The design is disposable.

The video below clearly shows how to use piercing compresses:

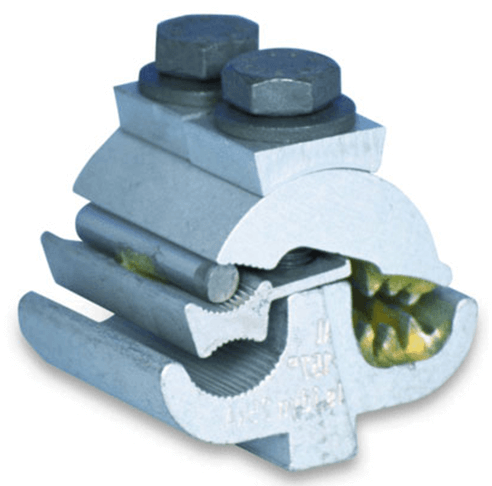

If the connection from the metering board on the pole to the house is made by means of self-supporting insulated wires, the standard one should also be used fittings. The best option is to lead the wire directly into the control box, connecting it to the input circuit breaker in the shield. In this case, it will not be necessary to fasten it with a cable. If for some reason the SIP and the copper cable need to be connected, this can be done on the street, at the entrance to the house. The connection can be made with a piercing clamp. In addition, the connecting installation can be performed using spot clamps, which are called nuts for their shape. More about nut type clamp You can find out from our article.

Clips of both types can connect current-carrying conductors of different materials, for example, a self-supporting insulated conductor can be connected to SIP, VVG, VVGng, AVVG or speakers. This is allowed by the design of the connector, ensuring the absence of direct contact of aluminum with copper. Each of the connected conductors is in contact only with steel plates.

How to use nuts is described and shown in the video:

The SIP connection with bare wires (bare) is carried out by a clamp of a special design that does not have sharp teeth on the side of the bare wire. This type of compression is depicted in the photo below:

It remains to add that it is not allowed to connect the wires of copper and aluminum together by twisting due to the occurrence of electrochemical corrosion! This issue is considered in more detail in the article: https://our.electricianexp.com/en/kak-soedinit-alyuminievyj-provod-s-mednym.html.

The metering board is located on the wall of the house.

In this case, a tap connected to the trunk line with a tap clamp is inserted directly into the metering board and connected to the input circuit breaker. In the event that the self-supporting conductor is a self-supporting insulated wire, anchor clamps are installed on the line support and on the wall of the house to secure the wire. If a copper cable is chosen for fastening the line and the metering board, it is necessary to tighten the steel cable on which the cable should be fixed, since it is not designed for the tensile load.

It may be necessary to connect a SIP and a copper cable in this embodiment if there are several buildings on the site and the power wiring for them is made by the SIP. Installation in this case can be performed in the same way as described above, using a piercing or die clamp.

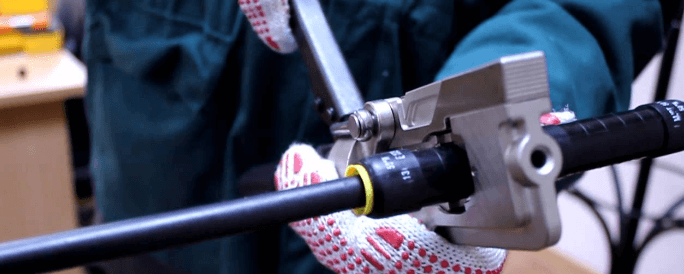

Sometimes you can see how the connection of a self-supporting insulated wire with a copper cable is performed using a sleeve that requires subsequent crimping.

This is unjustified for several reasons:

- The installation of sleeves requires special equipment.

- MJPT sleeve clamps are designed for butt connection of SIP wires of one section during repair or installation of trunk lines. The technology used provides the mechanical strength of the bonding point necessary to maintain the bearing properties of the repaired wire. The cable connection with SIPom at the power input of the house does not bear a mechanical load.

- Non-insulated copper sleeves serve to restore the conductors of a conventional cable, after which the coupling is mounted on this place.

Connector installation technology is provided in the video:

SIP connection among themselves

The methods of such a connection depend on the goal that is being pursued. The bonding of wires to each other on a support can be of two types:

- butt end-to-end connection during repair or installation, when the length of a solid wire is not enough;

- a branch from the trunk line to power the consumer.

In the first case, MJPT clamps are used, as mentioned above. In the second case, it is enough to connect the wires with a piercing clamp.

That was all I wanted to tell you about how to connect a SIP with a copper cable and with each other. We hope the information provided was useful and interesting for you!

Surely you do not know: