Tools and fixtures for mounting SIP

Auxiliary fittings for mounting a self-supporting insulated wire can be of different purposes, namely:

- for connecting conductors;

- for hanging wires on a support or anchor;

- for tensioning the SIP overhead line;

- for connecting contact connections and branches;

- protective auxiliary compounds;

- fittings for gearing;

- spiral reinforcement.

Let's consider them in order. The first thing I would like to talk about is the rollers for rolling the wire.

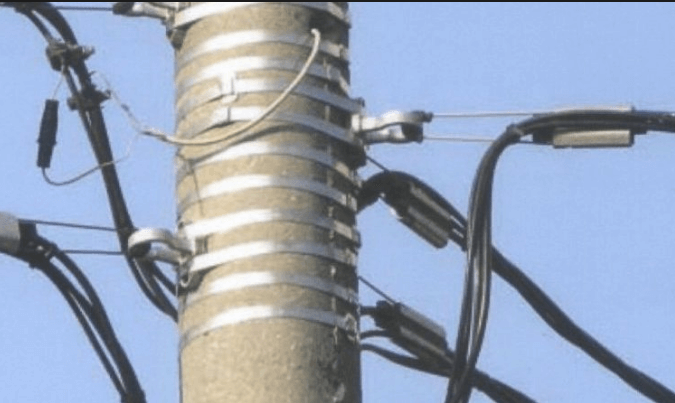

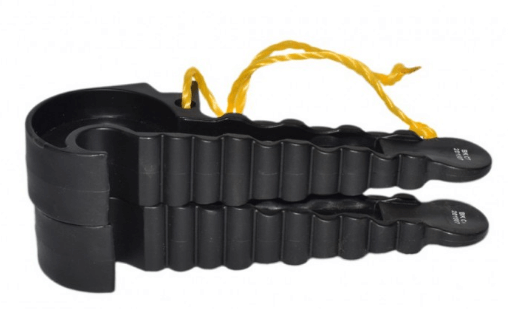

When drawing an electric line, care must be taken not to spoil the insulating layer, to avoid dragging along the ground, along tree branches and other surfaces. To do this, they resort to dragging along the rollers, which are temporarily mounted on poles, in the places of the future location of the wire.

To reliably fix the auxiliary equipment on the support, galvanized metal tape is used.

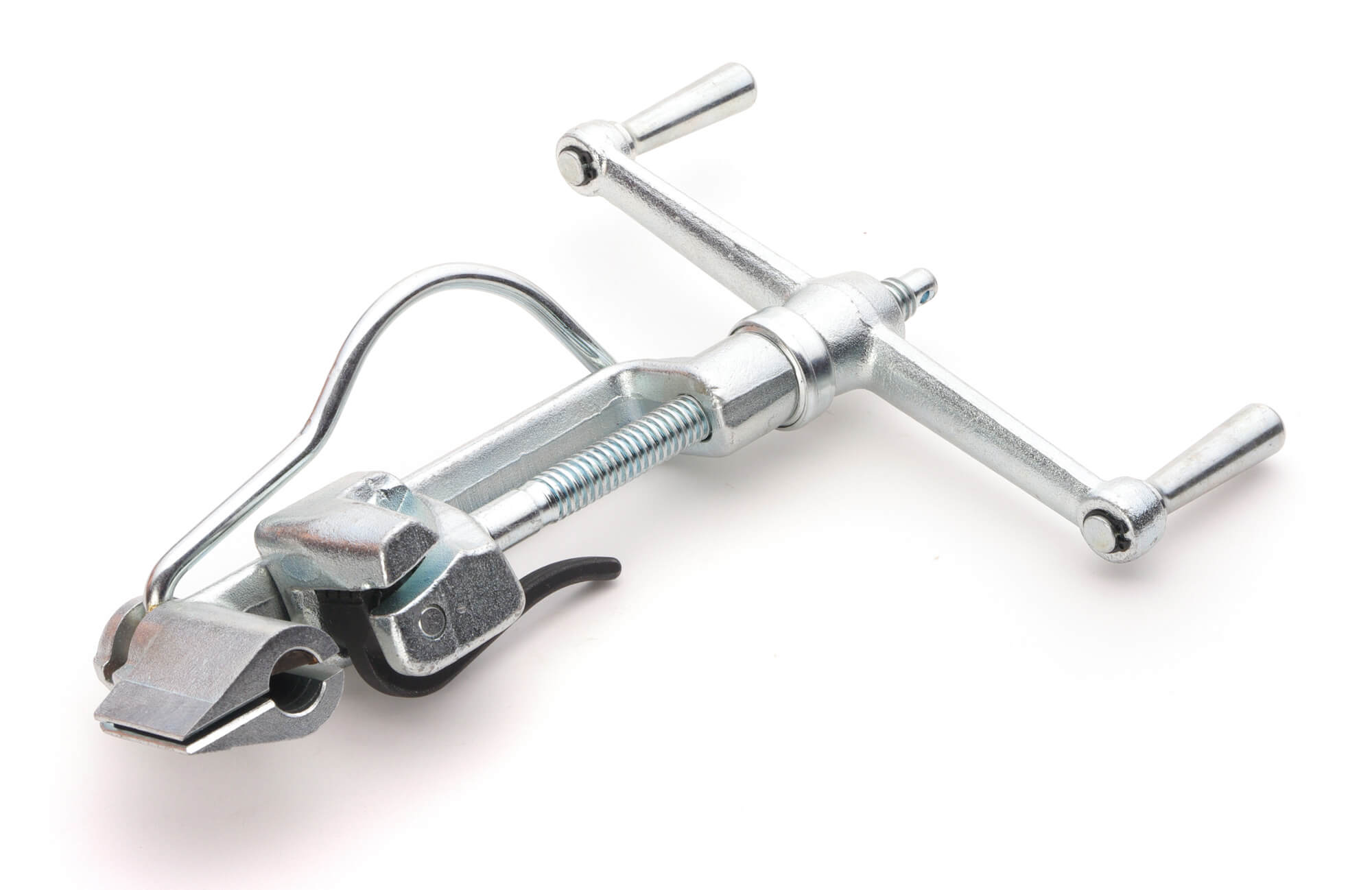

To tightly clasp a support, the tensioner pulls a previously cut piece of tape around the post, compresses the bracket, tightly fixing it, and cuts off the excess tape.

Fixing hooks are used to perform quick installation of various SIP fittings on the support, poles and facades of buildings. They differ in the type of fastening.

High-quality scissors that do not leave skews, sharp edges and edges are useful for smooth cutting of a metal tape. They allow you to perform cutting with one hand quickly and efficiently, which is certainly appreciated when working at height in cramped conditions.

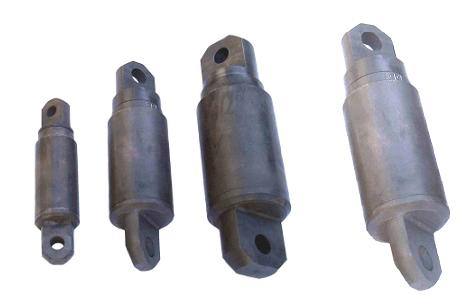

To compensate for torsion and prevent the appearance of loops on the SIP wire, as well as to prevent twisting, you can use a device such as a swivel, which is used during installation.

In order to roll the wire along the rollers, it is necessary to stretch the cable along them and connect it to the cable, avoiding damage and knots. This can be done using special tightening stockings. The weave of the stocking is made so that when it is pulled, an extensive contact area is created and the insulation of the conductor is not damaged.

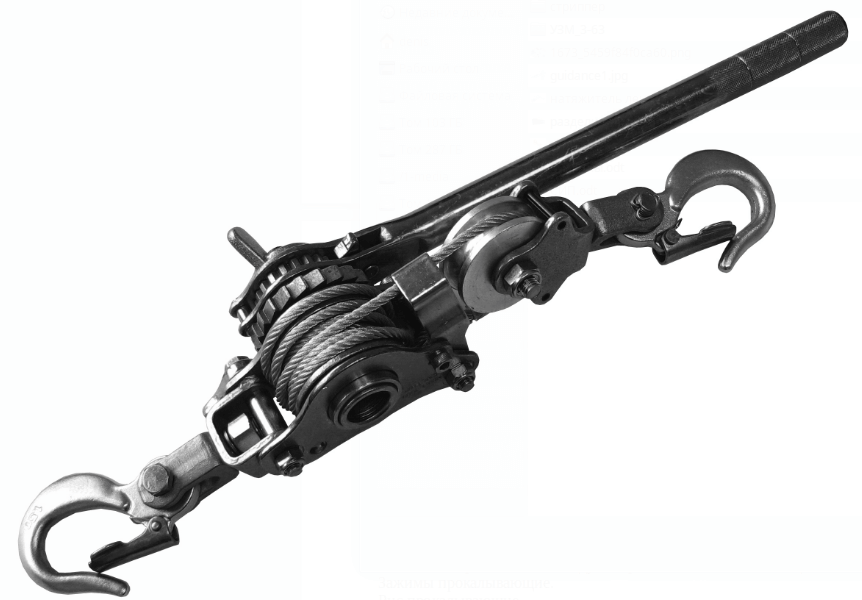

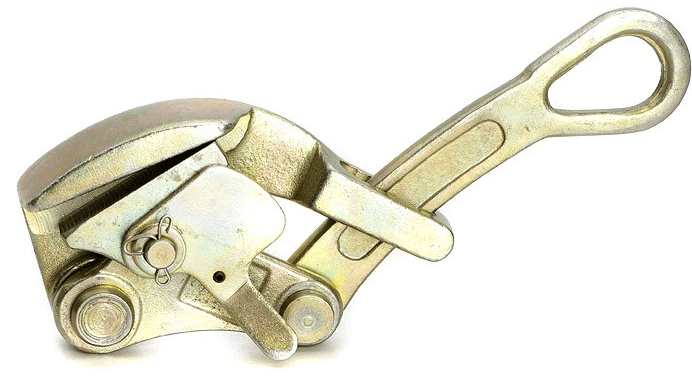

A winch is used to tension the wires and eliminate the sag of the overhead line. The use of this device in conjunction with a dynamometer allows you to correctly install the tensioned wire overhead line.

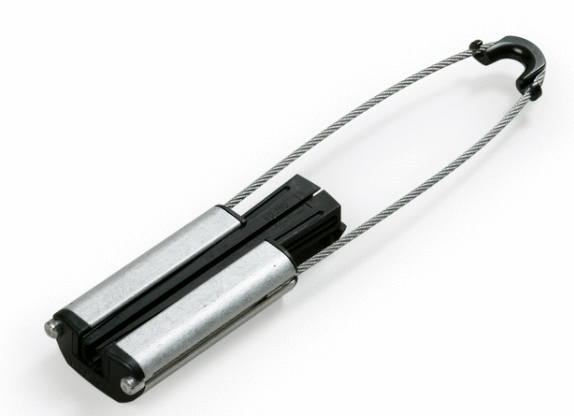

For hanging and fixing the stretched conductor, special mounting clips are used.When using a self-supporting insulated wire with an insulated carrier neutral, a thunder-frog clamp is used.

It is made of a material resistant to environmental influences. Also, during the installation of self-supporting insulated wires, we will need anchor and supporting reinforcement, depending on the place of use (support or building facade) and other sections of overhead lines and branches from it.

Before installing the couplers on the wire, it is necessary to separate the prepared core from the SIP harness.To do this, there is a phase separator - a wedge of a special shape that takes the core to the desired distance, facilitating the installation of branch clamps.

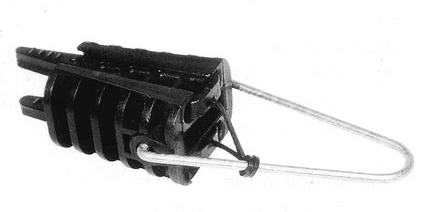

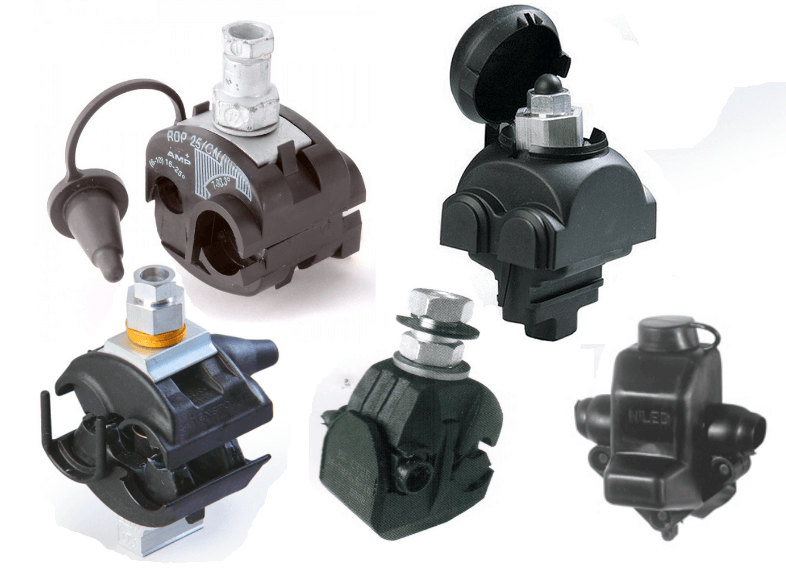

To connect to the SIP wire, two types of clamp adapters are used.Branch and piercing clamps. First are used for trunk equivalent branches. The clamp consists of three plates, between which clamped conductive conductors are clamped. It is also called the "nut." How to use wire connection nut, we told in a separate article.

To connect the branches from the trunk, use piercing clamps. When choosing compresses, you need to know the cross section of the trunk and branches, based on this, make a choice.

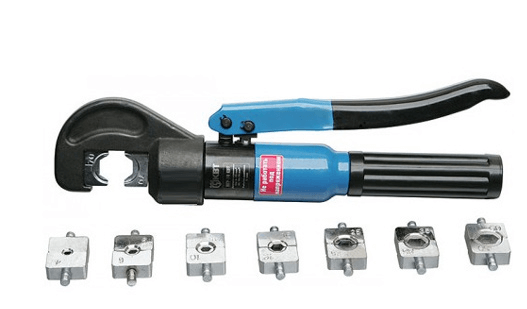

To crimp the tips, the ends of the SIP wire, which can be inserted into the input or registration board, you may need a press for crimping the tips and special dies. With this device, the contact of the core with the tip is obtained with the highest quality.

In addition to all the above-listed fittings, it is necessary to have a special protective lubricant (NILED), which prevents the increase in contact resistance, and also does not allow the appearance of an oxide film on the aluminum wire. Its use increases the service life.Tape (NILED) is used to restore insulation on the self-supporting insulated wire and to level the surface under heat shrinkage. This tape, based on a special bridge, has high resistance to ultraviolet and ozone.

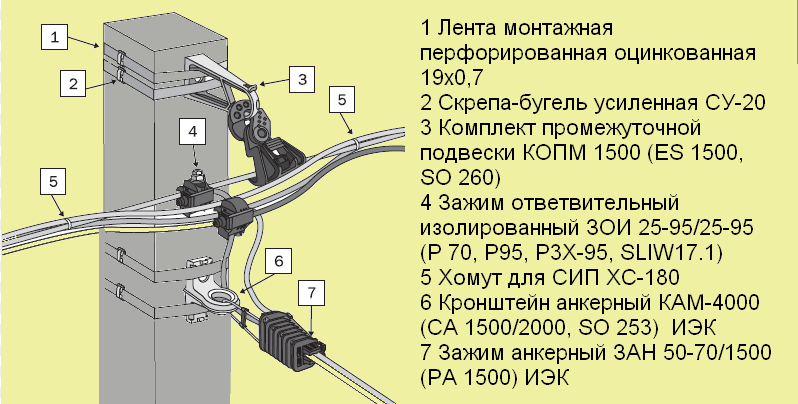

An example of installation with a description of the fittings for mounting the self-supporting insulated wire you can see in the picture:

We also recommend that you watch the video lesson, which clearly shows what tools and devices are used to install the SIP wire:

This is where we end the review of all tools and fixtures. Now you know what kind of fittings are for mounting a SIP cable from a pole to a house.

It will be useful to read:

how do you distort the language, listening to you is painful but informative.