How to lay wiring in the cable channel

What is important to know

The main structural element of the electrical box is the profile of the U-shaped section, the length of which is 2 meters. The product includes a cover to close the internal cavity of the product. The profile is attached to the wall or ceiling, it is the laying of power cables or control wires, after which the wiring is closed by a quick-release lid.

As the material from which the boxes can be made, galvanized steel, aluminum or durable plastic that does not support combustion is used. Learn more about what are the cable channels, you can from our separate article.

The range of products that perform the functions of the cable channel is very diverse, as can be seen in the photo above. It can be wall boxes and floor skirtings, as well as corrugated pipes and trays. As a rule, skirting boards are designed to accommodate low-current cables and wires, corrugated pipes and trays are used for installation in utility rooms and on the surface of external walls.

For arranging the power supply of the premises, the most popular were wall-mounted electrical boxes made of plastic with a double-sided lock. In addition to the most common white cable channels, the industry has launched the production of products of various colors that can complement the interior of any room.

Preparation for work

Before laying the cable in the cable channel, it is necessary to think over the scheme and installation technology. First of all, a working drawing is created, indicating the types and number of conductors that are planned to be laid. Based on the sketch, you need to purchase the necessary number of boxes, accessories, switches and sockets.

Before doing fixing the cable duct to the walls, you need to mark the route of the wiring.In places where cable lines are laid, there should be no threat of mechanical or thermal damage. The location of switches and sockets should ensure convenient and safe use of them.

When buying electrical accessories, it is necessary to check the serviceability of the locks fixing the product cover, which should close with a distinctive click and hold firmly on the profile. Spontaneous opening is excluded.

Mounting Methods

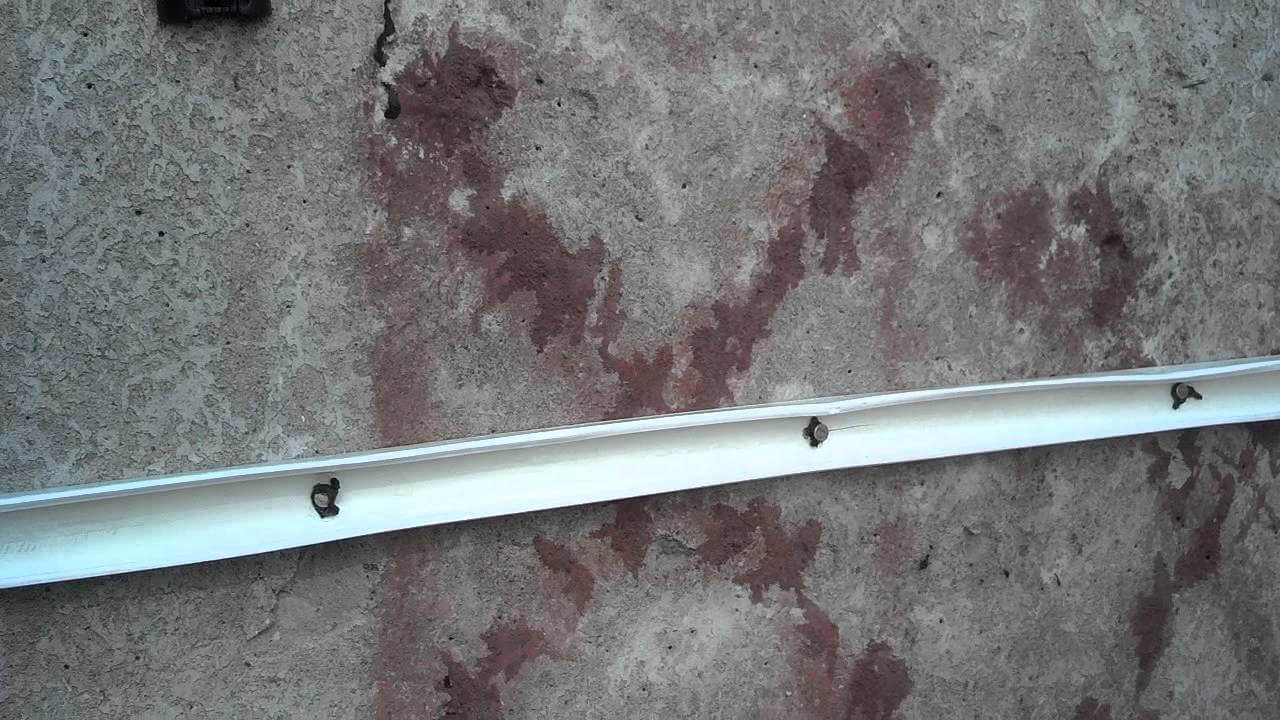

Depending on the material from which the walls are made, several methods are used to secure the cable channel. In order for the mount to provide a secure fit, pleasing to the eye and provide aesthetic pleasure, it is necessary to level the surface of the walls before laying.

A plastic product can be attached to the walls with glue, which can be used as reliable and tested liquid nails. This is the easiest way, however, it is fraught with significant difficulties if there is a need for dismantling. This method does not give the master the right to make an error with fasteners. It is better to fasten the box to the tree using self-tapping screws. The size of the mounting step should be maintained within 50 centimeters. Self-tapping screws should be inserted into pre-drilled holes in the profile, the value of which should slightly exceed the diameter of the fastener.

To fix it on a concrete or brick wall, you will need a puncher, a drill with a 6 mm diameter drill bit and a dowel-nails. For each two-meter section, a strand of 4 to 5 dowel-nails will be required. Boxes intended for fastening with adhesive tape are usually used for arranging temporary power supply.

When laying boxes, measurements should be carefully taken and care should be taken when cutting. The golden rule, which should not be forgotten, in order to avoid marriage, cutting should be done with the lids closed. You should know that cutting plastic profiles and covers must be done with a hacksaw for metal or a grinder. In order to avoid the formation of chips and cracks in the places of cutting, the use of wire cutters or scissors for this purpose is not permissible.

Ultimately, the assembled structure should not have visible gaps at the joints. In places of corner joints, it is advisable to use special accessories that hide assembly flaws.

Mounting Features

After the fastening is completed, the wiring in the cable channel begins. To prevent the cable from falling out during the installation period, it is recommended to install short trimmings of the cover on the locks along the entire length of the cable channel. If power and control cables are required to be laid in the channel, the internal cavity of the box must be divided into two sections in order to exclude the intersection and twisting of low-current lines. We wrote more about this in the article. https://our.electricianexp.com/en/kak-nuzhno-prokladyvat-kabel-v-lotkax.html.

The size of the channel cable should be selected so that the cables laid in it do not fill its cross-section in the light by more than 40%, so recommends chapter 2.1. PUE paragraph 2.1.61. Although we are discussing laying in cable channels, we believe that this requirement must be observed in this case too.

The cover should close effortlessly and be locked securely.

For those who do not have experience in such work, you should purchase a common meter cable channels with a small margin, taking into account the marriage and errors. The video below clearly shows how to properly draw a cable line in a special plastic channel:

That's the whole technology by which the cable is laid in the cable channel. As you can see, there is nothing complicated, the main thing is to securely fix the box on the wall and take into account the recommendations provided in the article! We hope our step-by-step instructions came in handy and helped you do the electrical installation yourself!

It will be useful to read:

I wonder how you say that there are no restrictions on the number of cables laid in the channel when they are.

PUE

2.1.61. It is allowed to lay wires and cables in boxes in a multilayer manner with an ordered and arbitrary (in bulk) mutual arrangement. The sum of the cross-sections of wires and cables calculated according to their outer diameters, including insulation and outer sheaths, must not exceed: for deaf ducts 35% of the cross-section of the duct in the light; for boxes with openable lids 40%.