How to check if the capacitor is working?

Preparatory work

Before checking the health of the capacitor, it is necessary to discharge it. To do this, it is best to use a conventional screwdriver. With a sting you must touch the two outputs of the keg at the same time so that a spark arises. After a small flash, you can proceed to the health check.

Method number 1 - Multimeter to help

If the capacitor does not work, then it is best to check its performance with a multimeter or a workshop. This device allows you to determine the capacity of the "Conder", the presence of a break inside the barrel or a short circuit in the circuit. About, how to use a multimeter We have already told you, so we recommend that you first read this article. If you know how to work as a tester, then things are much simpler.

First of all, you must determine which capacitor is in the circuit: polar (electrolytic) or non-polar. The fact is that when checking a polar product, you need to observe the polarity: the plus probe should be pressed to the plus leg, and the minus, respectively, to the minus. In the case of a non-polar version of the part, it is not necessary to observe the polarity, but it will also have to be checked using a different technology (we will talk about this below). After you decide on the type of element, you can proceed to the verification work, which we will now consider in turn.

Measure resistance

So, first you need to check the capacitor resistance with a multimeter. To do this, unsolder the barrel from the circuit and with the help of tweezers carefully move it to the working surface, for example, a free table.

After that, we switch the tester to the dialing mode (resistance measurement) and touch the probes to the terminals, observing the polarity.

We draw your attention to the fact that if you confuse the minus with the plus, the performance test may fail, because the capacitor will immediately fail. To prevent this from happening, remember the next moment - manufacturers always mark the negative contact with a tick!

After you touch the probes to the feet, the first value should appear on the display of the digital multimeter, which will immediately begin to grow. This is due to the fact that the tester starts charging the capacitor upon contact.

After a while, the maximum value “1” will appear on the display, which indicates the serviceability of the part.

If you just started to check the capacitor with a multimeter, and you got “1”, then there was a break inside the barrel and it is faulty. At the same time, the appearance of zero on the scoreboard indicates that something happened inside the conder short circuit.

If you decide to use an analog multimeter (arrow) to test the resistance, then it will be even easier to determine the element’s performance by observing the course of the arrow. As in the previous case, the minimum and maximum values will indicate a breakdown of the part, and a gradual increase in resistance will mean the suitability of a polar capacitor.

To independently verify the integrity of the non-polar conder at home, it is enough to touch the feet of the tester with the probes without observing the polarity, setting the measurement range to 2 MΩ. The display should show a value greater than two. If this is not the case, the capacitor is not working and needs to be replaced.

It should also be noted that the verification method provided above is only suitable for products with a capacity of more than 0.25 uF. If the face value of the circuit element is less, you must first make sure that the multimeter is able to work in this mode, well, or buy a special tester - an LC meter.

Measure capacitance

The next way to check the operability of the product is to breakdown by measuring the capacitive characteristics of the conder and comparing them with the nominal value (indicated by the manufacturer on the outer shell, which is clearly visible in the photo).

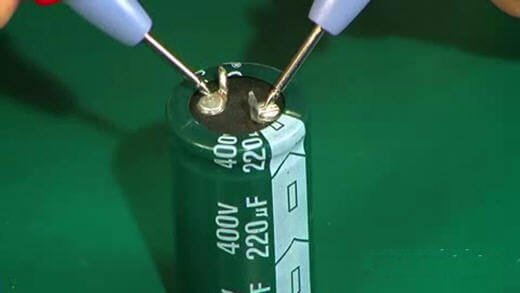

It is not at all difficult to independently measure the capacitance of a capacitor with a multimeter. It is only necessary to transfer the switch to the measuring range, relying on the face value and, if the tester has special landing slots, insert the part into them, as shown in the photo below.

If there is no such function in the tester, you can check the capacity with the help of probes, similar to the previous method. When connecting the probes, the display should show a capacitance that is close in value to the nominal characteristics. If this is not so, then the capacitor is broken and you need to replace the part.

Measure voltage

Another way to find out if a capacitor is working or not is to check its voltage with a voltmeter (or a "multicom") and compare the result with the nominal value. For verification, you will need a power supply with a slightly lower voltage, for example, for a 25-volt conder, a 9-volt voltage source is enough. Observing the polarity, connect the probes to the legs and wait a few seconds, which is enough to charge.

After that, put the tester in voltage measurement mode and perform a functional check. At the very beginning of the measurement, a value approximately equal to the nominal value should appear on the display. If this is not the case, the capacitor is faulty.

We draw your attention to the fact that when a voltmeter is connected, the barrel will gradually lose its charge, therefore reliable voltage can only be seen at the very beginning of measurements!

I would also like to say a few words about how to check a large capacitor in a simple way. First you must fully charge the element for several seconds, and then close the contacts with a regular screwdriver with an insulated handle. If the barrel is working, a bright spark should appear. If there is no spark or it is very dim, most likely the capacitor does not work, or rather, it does not hold a charge.

Was any step in the verification incomprehensible to you? Then review the technology for checking the performance of a capacitor with a multimeter in this video tutorial:

Method number 2 - do without appliances

A less high-quality way of checking the performance of a capacitive element is with the help of a home-made sound in the form of a light bulb and two wires. In this way, you can only check the capacitor for a short circuit. As in the case with a screwdriver, we first charge the part, after which we touch the legs of the probe leads. If the conder works, a spark will occur that will immediately discharge it. About, how to make a test lamp electricianWe also told.

What else is important to know?

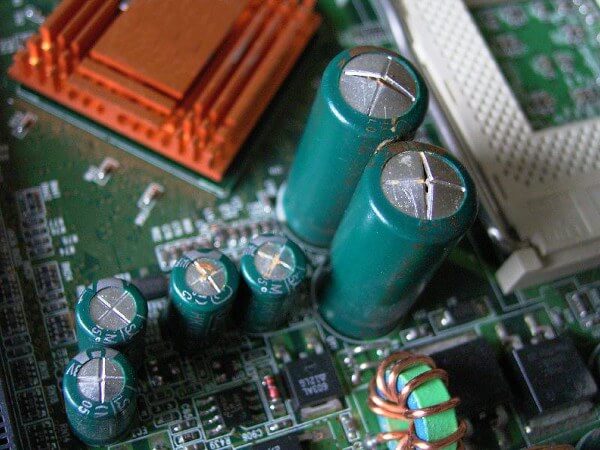

Not always checking the performance of the capacitor requires the use of a multimeter or other testers. Sometimes it’s enough to visually look at the external condition of the product, to check for bloating or breakdown. First, carefully look at the top of the barrel, on which the manufacturer has drawn a cross (a weak spot that prevents the Conder from exploding if it fails).

If you see leakage or destruction of insulation there, it means that the capacitor is broken, and there is no sense in checking it with a tester. Also, carefully check if this circuit element has not darkened or has become bumpy, which happens very often. Well, we should not forget that damage may have occurred on the board itself near the connection point of the capacitor. This malfunction can be seen with the naked eye, especially when there is a peeling of the tracks or a change in the color of the board.

Another important point that you must take into account is that the product must be checked only by removing it from the board. If you want to check the capacitor without evaporating from the circuit, note that there may be a large measurement error due to the other elements of the circuit nearby.

That's all I wanted to tell you about how to check the performance of a capacitor with a multimeter at home. We recommend that you use this manual when microwave repair or do-it-yourself washing machine, as This type of household appliances very often has this breakdown. In addition, the Conder often stops working on air conditioners, amplifiers, and even video cards. Therefore, if you want to repair anything on your own, we hope that this instruction will help you!

Also read:

everything is correct only imported cond punched on them or you can’t see anything and check well by connecting them to the 220 network through a light bulb or an 1-2 amp automatic circuit if it doesn’t work, it means good and after that connect an alternating current ammeter and measure the current through the cond and approximately according to current determine the capacity of the cond

Hello!

Tell me please, the multicooker moulinex serie epc03 cook4me-ce701132 turns on and off on its own (chaos, I can enter the code, I don’t have time), it doesn’t give an error, I can’t even enter the service mode to reset the code 5923 and read the error, what is it?

Sockets and plug checked, excellent contacts! The fuses are intact, there are no external damages, there are places contaminated with food, cleaned.

Conder can be measured by drinking and one leg.

I would like to see how you do it.

Do you need to make the legs of the capacitors so short, what other pole designations are there? If 34 Volts, then the tester with a 9-volt battery will not smoke anymore?

capacitors are made with long enough leads, they are bitten after soldering. About the voltage - it does not matter. The capacity is the same at 9 and at 20 and at 34 volts.

Is soldering a condenser necessary? And if you connect it from the back of the board?

There he is not alone in the chain.

for accurate verification