How to measure cable insulation resistance?

What devices do they use?

Before starting work, you need to measure the ambient temperature. Why is this necessary? If the cable line has water particles during freezing temperatures, then they turn under the influence of frost into ice, and ice is a dielectric that has no conductivity. Therefore, when the resistance is measured at a negative temperature, these ice floes will not be detected.

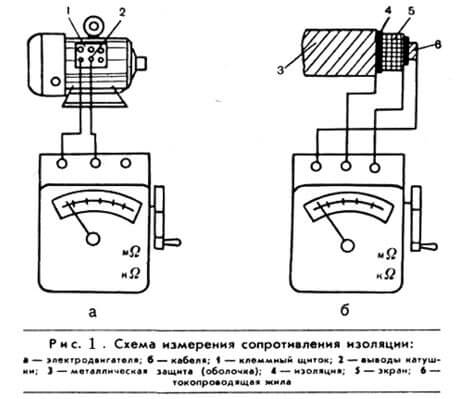

Then, in order to measure the insulating layer of the wiring (its resistance), it is necessary to have special instruments and diagnostic tools. You can measure the resistance with a special device called a megaohmmeter (pictured below).

A megaohmmeter can measure resistance to a voltage of 2500 V (isolation of low-voltage and high-voltage lines). The measurement takes place at a voltage of 500–2500 V of the control power lines (control circuits, power circuits, short circuit etc.).

Such devices must undergo state verification every year, as a result of which a stamp is placed, which indicates the serial number and the date when it is necessary to pass the next verification. Each cable has its own standards, GOST and PUE, according to which checks and tests of wires are carried out.

Test Methodology

Before you measure the insulation resistance of wires and cables, you must perform the following steps:

- Check instrument status. To do this, check the direction of the arrow when the wires are open (the arrow points to infinity) and the wires are closed (points to zero).

- Check for lack of power. The wire must not be live.

- Ground the cable to be tested.

The measurement differs depending on the classification of the lines of force, but these differences are not significant. For example, the control cable has its own distinctive feature: in order to measure the resistance, the wire does not need to be disconnected from the circuit.

The insulation of the devices is checked with the help of special devices, which are forbidden to touch during testing. The readings should be taken only when the arrow of the device has taken a stable position. Measurement is carried out within one minute. With electronic devices, things are faster and the result is displayed immediately on the screen. All data should be written to a notebook.

After all the data has been obtained, it is necessary to draw up an act and a test report. First of all, it is necessary to compare the obtained values with existing norms and requirements. Then conclude: is the cable suitable for further use. And only after that draw up a protocol for measuring the cable insulation resistance. A sample protocol is provided in the photo below:

More about how to use a megaohmmeter, you can find out from our article!

How often do measurements take?

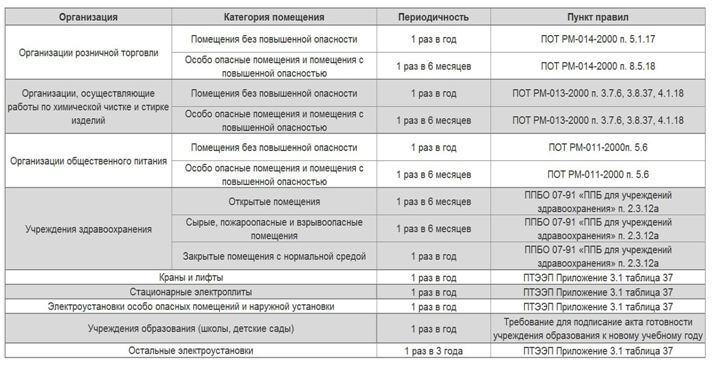

In organizations of small sizes, resistance is measured once every three years (according to GOST and PTEEP). The insulation of the wiring is recorded in the protocol, which in addition to measurements, indicates RCD health check.

Measurement of insulation resistance at facilities with increased risk should be carried out every year. These are rooms where there is high humidity or high temperature. In industrial plants, such a measurement will prevent or avoid equipment shutdown. After the inspection of the equipment has been carried out, a special report is drawn up, which fully indicates the status of the electrical installations.

Measurement should be carried out according to the established terms. After all, thanks to this, various emergencies that can have serious consequences can be avoided in advance. Also, an untimely audit carries fines imposed by the relevant authorities.

Below is a diagram of the frequency of inspections depending on the classification and category of premises:

Who is checking and why is this needed?

In order to measure resistance, you must have special permission and access. Based on this, only special companies and organizations that have qualified employees can test the cable. They must undergo appropriate training and receive the required level of electrical safety.

Measurement is necessary in order to identify damage to the equipment in advance. After all, insulation plays a significant role in the safety of working with electrical equipment. If the cable or wire is damaged, then the electrical installation becomes dangerous during operation. After all, a wire or cable can catch fire and cause a fire. If you check the cable in advance for the working condition of the insulating layer, this will prevent from such troubles as:

- premature equipment failure;

- wiring short circuit;

- electric shock to the worker;

- emergency situations of a different nature.

That is why it is very important to measure the insulation resistance of the cable. Finally, we recommend watching a useful video on the topic:

Now you know how to measure the insulation resistance of wires and cables. We hope that the provided instruction was useful and interesting for you!

Surely you do not know: