Processing of cable lines with flame retardant

What is it for?

Handling cable routes with fire protection is extremely important and necessary. The main factors are:

- the accumulation in one place of a large amount of combustible materials;

- the presence of possible sources of ignition;

- the length of the electric lines is very large.

Processing the cable with protective paint against fire can protect against fire and prevent various unpleasant moments. For instance:

- A fire that cannot be controlled and controlled. If you do not pre-treat the conductors with fire-retardant paint, then in the event of a fire, the fire in the entire building may become uncontrollable. After all, cable passages are very narrow and it is very difficult to extinguish them.

- Toxic and hazardous fumes. The electric cable coating contains a hazardous substance that can be harmful to human health and life. It is used to give elasticity to conductor insulation. As a result of combustion, this substance is converted to hydrogen chloride.

- Damage to metal structures. As a result of combining a harmful substance from the composition of the insulation with water, concentrated hydrochloric acid is formed, which causes harm to metal structures. Fireproof cable treatment helps protect the surface and neutralize hazardous chemicals.

During various tests in the laboratory and the personal practice of specialists showed that fire retardant coating allows to achieve such important goals:

- reduce burning rate;

- reduce the number of vapors of hazardous substances and their toxicity;

- reduce the heating temperature;

- possible cause of self attenuation.

The building regulations and rights (SNiP) indicate the necessary requirements according to which fire protection is considered necessary for complex power supply systems. When a large flow of electricity is concentrated in one place, the cable is treated with fire-retardant paint.

Types of fire protection

How to calculate the amount and consumption of thermal paste? Fire-retardant coating of cable lines occurs before performing basic work. The paste for processing must be selected correctly and be the most optimal.Fire protection, which is applied to the cable in the form of fire-retardant paint, must comply with all application rules and not interfere with such moments as:

- Replacing electrical wiring, cable lines.

- Raise the heating temperature. With proper implementation of the rules of application and proportioning of the solution for processing, the flame retardant will interfere with emergency heating.

- During use, fire protection should not reduce the load.

Regulatory documents prescribe the basic requirements according to which, for cable lines, in addition to the paint material, the layer thickness is calculated. How to calculate the flow rate and thickness is indicated in GOSTs. Fire-retardant coating of electrical cables is only authorized by an organization that has a special license. Such restrictions are indicated in the requirements of SNiP.

It is also necessary to choose a fireproof coating of the box and the tray. The composition of the product must meet all the requirements. To do this, apply:

- Paint against the fire. It is popular for its high level of protection. The conductor is painted in rooms where access is restricted. The term of use is 10 years.

- Paste. It is applied manually using a roller or brush. Highest degree of protection for the lines in the box and in the tray.

The video below demonstrates the effectiveness of applying fire protection to the cable:

Processing order

According to special documentation, it is provided that fire-retardant coating should be carried out according to the existing provisions of the PPB, where such moments are indicated:

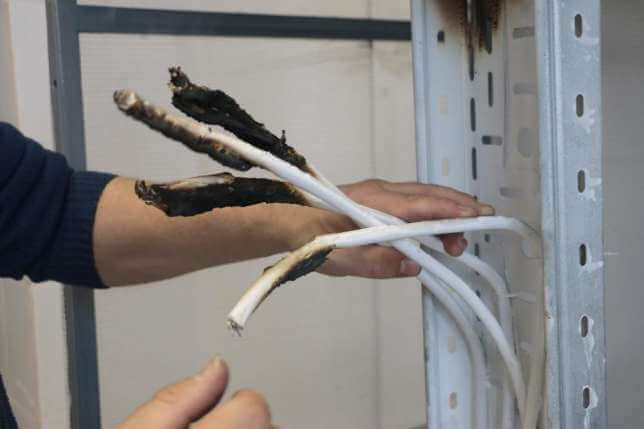

- Inspection of the condition of the cable product. If during the inspection it is found that the conductor and the integrity of the winding are damaged, then the fire retardant coating is not applied. Further processing is terminated until the damage is repaired. If the conductor is dirty, it is forbidden to apply paint or paste. About,how to find cable damageread in our article!

- Fire retardant coating. It is necessary to draw up a processing protocol. Work is underway to protect cable products. The protocol prescribes the type of fire protection that will be processed. For example, the use of inorganic refractory paint is permissible only in closed rooms, since its use in the open air can lead to a loss of the refractory properties of the power cable.

- Completion of processing. Inspection of fire retardant coating. Normative documents are signed. If the composition is not applied according to all requirements and the conductor is coated incorrectly, then the employee of the Ministry of Emergencies has the full right not to accept work.

The technology of applying fire protection has its own nuances. The cable is processed according to a special technique, which is indicated in the PPB. It also makes it possible to assess the degree of danger of the cable line after processing it against a fire.

For you to understand, the insulation of cross-linked polymer burns with a speed of 0.2-0.5 m / min, under acceptable conditions, the speed increases by 4 times!

Rastrata spent on the application of fire protection, justify themselves. After all, if we take into account the costs of the subsequent fire, they are negligible. That's all we wanted to tell you about fire retardant coating of cables.

Surely you do not know:

For outdoor installations, on cable racks, in case of cramped space, is it possible to treat the cables with fireproof paint to separate the cables? thank