AABl cable specifications

Label design and interpretation

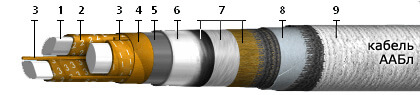

The cable design is demonstrated by a photo showing, for example, AABl - 6 kV, of which each insulating layer consists of:

Conductors (1) AABL are made of aluminum. This is evidenced by the first letter "A" in its designation. In the cross section, the core has a sectoral shape, structurally it can be either single-wire or multi-wire. The fact that the conductive core is monolithic, or single-wire, is indicated by the coolant letters present in the marking. Each core is wrapped with paper tape (2) impregnated with a non-leaking insulation composite. For ease of installation, digital or color cores. In the intervals between the phase insulation, the filling (3) made by paper tows is laid, followed by the so-called belt insulation layer (4). Belt insulation is also impregnated with a viscous insulating compound.

The number (5) in the photo indicates the conductive screen of special paper. Such a screen is included in the design of high-voltage cables designed for operation in networks of 6 and 10 kV. The screen is followed by an aluminum shell (6), this is how the second letter “A” is deciphered in the marking Able. This is followed by a bituminous pillow (7), wrapped with polyvinyl chloride (PVC) tape, and on top with special crepe paper. The presence of plastic ribbons in the pillow is determined by the presence of the letter “L” in the marking. The pillow performs moisture protective functions, and also serves as the basis for winding on top of the armor layer of two steel tapes (8). Tapes can be made of ordinary black steel, or galvanized. Their thickness is in the range of 0.3 - 0.8 mm. The armor is covered with a layer of fiberglass or special cable yarn (9), which is impregnated with a viscous bituminous composite that performs the function of protecting the armor from corrosion, as well as preventing the cable coils from sticking together during storage.

The design of the AABL cable is clearly shown in the video:

Specifications

AABl-1:

- Operating voltage level at a frequency of 50 Hz - 1 kV.

- The maximum permissible continuous heating of the cores is 80 ° C.

- Short-term warm-up in emergency mode - 105 ° С in overload mode, 250 ° С during short circuit.

- The smallest bending radius is 25 outside diameters.

- Operation at a temperature from -50 ° C to + 50 ° C is allowed.

- Declared by the manufacturer for a minimum service life of 30 years.

AABL-6:

- Operating voltage 6 kV, frequency 50 Hertz.

- Long-term allowable heating of conductors 65 ° C-80 ° C (depends on the composition of the insulation impregnation).

- Heating lived in an emergency mode of 90-105 ° С at an overload, 200 ° С in the KZ mode.

- Mounting bend with a radius of at least 25 diameters.

- The temperature range of the medium is from -50 ° C to + 50 ° C.

- The standard life of 30 years or more.

AABL-10:

- The rated voltage value is 10 kV at a frequency of 50 Hz.

- Operational heating of veins (long) 60-70 ° C.

- Heating at a deviation from the normal mode of 80-90 ° С at an overload, 200 ° С in the KZ mode.

- The temperature of the medium is from -50 ° C to + 50 ° C.

- The guaranteed service life established by the manufacturer is 30 years.

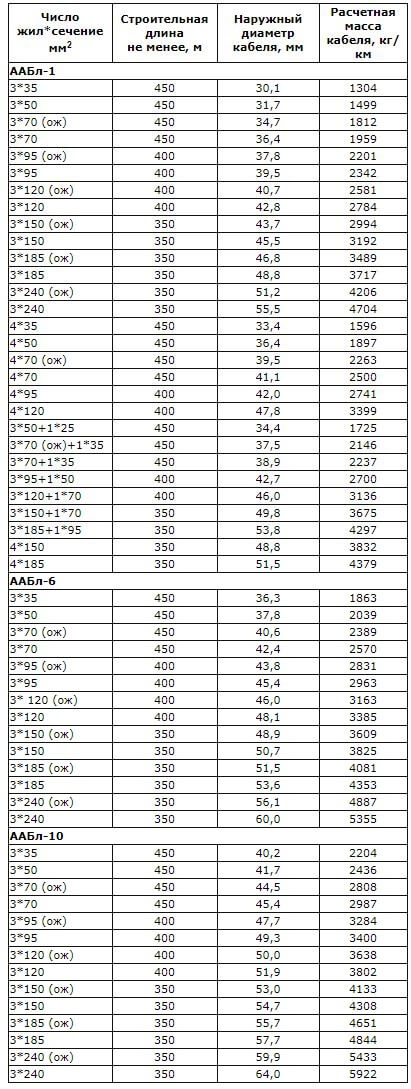

The remaining characteristics of the AABL cable, as well as the cross sections, are summarized in the table:

Laying Rules

AABL cable is intended mainly for laying in earthen trenches. This installation method has several advantages. Cable laying in the ground provides improved technical characteristics of the cable line, as it reduces the likelihood of mechanical damage to the insulation as a result of external influences. With this installation method, there is no need to build special supporting structures - cable trays, overpasses. This is especially true when it comes to power supply systems for facilities located in the city, in particular, residential areas.

Installation of the cable line is carried out in accordance with the project, which determines the route, profile and depth of the trench into which the installation should be made. Project details take into account technical characteristics, such as the outer diameter of the conductor, voltage class, as well as terrain conditions, the nature of the soil and other parameters. Building codes prescribe cable laying in a sand cushion. A protective layer of moisture-resistant brick or concrete slabs is laid on the sand, after which the soil is filled up. When installing the cable line underground, it is advisable to avoid connections, for which it is necessary to order the required building length of the cable. This is especially important for cables operating above 1000 volts. The experience of operating underground cable lines shows that the most common place for damage to the power line is a connector located underground.

Manufacturers

AABL cable production is currently carried out at several large plants: Kamkabel, Kavkazkabel and Saranskkabel. One of these plants (Camcable) is listed top cable manufacturers. AABl is produced in accordance with GOST 18410-73, which regulates such technical characteristics as specific resistance of cores, permissible current, dimensions, linear weight, minimum and maximum cross-section.

So we examined the technical characteristics of the AABL cable, as well as the scope of this conductor. We hope that the information provided was useful to you and helped to answer all the questions!

Recommended reading: