Methods of measuring current in a circuit of direct and alternating current

Any electrical system can not do without calculating the current strength in circuits, conductors and devices. For example, when installing electrical wiring in a single-phase network or in a three-phase network, to calculate the thickness of conductors and circuit breakers, you need to know the current strength that will flow in these lines. Correct measurement is the key to the safe and reliable operation of any electrical device.

Current measurements are carried out not only for circuit calculation, but also for the diagnosis of electrical equipment (for example, measurements on a three-phase motor) and household electrical appliances (in the heater, bulbs, power supplies, USB chargers, etc.). Automotive electricians, to detect a malfunction in the electrical systems of the car (for example, in the cigarette lighter), measure the current strength on the battery or on the generator of the car. In this article, we will describe in detail how to correctly measure current in various situations.

How to measure current

In order to be able to correctly measure the current strength, it is not necessary to be a professional electrician, but you need to have some knowledge of electrical engineering.

What is current? The current strength is a physical quantity that is equal to the ratio of the amount of charge that passes through a certain surface in a while, to the value of this period of time. This value is measured in Amperes and is indicated by the letter "A". Although the definition of current strength sounds quite sophisticated, there is nothing complicated in this physical quantity.

But how to measure amperes? In order to measure current, you must have a specific tool or equipment for this. Typically, measurements in a DC voltage circuit are carried out with a multimeter or tester, and in alternating voltage networks with clamp meters or an ammeter.

But how to measure amperes? In order to measure current, you must have a specific tool or equipment for this. Typically, measurements in a DC voltage circuit are carried out with a multimeter or tester, and in alternating voltage networks with clamp meters or an ammeter.

D.C

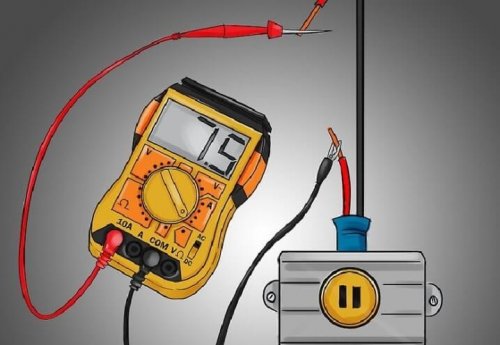

As already mentioned above, current measurements in DC voltage circuits are most conveniently carried out with a multimeter. In order to carry out the measurement, you need to take a multimeter and configure it to work with amperage.

To do this, the mode switch moves to the DCA position (direct current measurement), and the red and black plugs of the multimeter probes are connected to the sockets marked “10A” and “COM”, and the other ends are connected to the open circuit (that is, red is connected to positive polarity, and black to negative).

Modern Chinese multimeters have two sockets for measuring current strength. One of them is signed mA. It is protected by a fuse and is designed to measure low currents, often not more than 200 mA. And the second nest is signed either simply “A” or “10A”. It is not protected by a fuse and is designed to measure large currents.Moreover, the measurement time is usually limited to a period of 10-20 seconds.

Measurements are made from the maximum value, gradually decreasing to obtain the required dimension of the value on the screen. It is important to understand the approximate power of the electrical network in which the measurements are made and to choose a device in accordance with this. If the device is not designed for such a value, then it may fail or occur short circuit.

In everyday life, DC voltage current measurements are carried out, for example, at an LED on an LED strip or on a TV board (or other equipment) during its repair, as well as in other cases.

Many people think that to measure current strength you need to buy an expensive multimeter. But here you need to understand for what purposes and tasks the device will be used. If the work is performed by a professional electrician, then a more accurate and expensive tool is purchased, and home measurements can also be made with a Chinese multimeter.

Details on how to use the multimeter, we described in the article: https://our.electricianexp.com/en/kak-pravilno-ispolzovat-multimetr-prostaya-instrukciya-s-kartinkami.html.

Alternating current

Measuring the current strength in an AC circuit is more complicated than for a direct current. For this, devices such as an ammeter or clamp meters are used. Use of clamp meters - The most convenient and safe way, but it is only suitable for open wiring or cable. This method allows you to measure current without breaking the circuit, which is much safer and faster.

Measurement is carried out by placing a live conductor in a detachable magnetic circuit with a secondary winding (the design is almost similar to a current transformer). Due to the phenomenon of electromagnetic induction, it is possible to measure the secondary current in the winding, and after that the device calculates the primary in the measured circuit. When measuring with clamp meters, the conductor is inserted into the clamp solution and the display shows the current strength in the alternating voltage circuit.

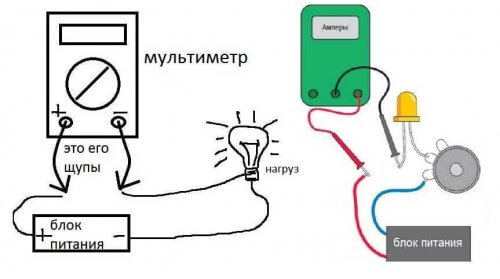

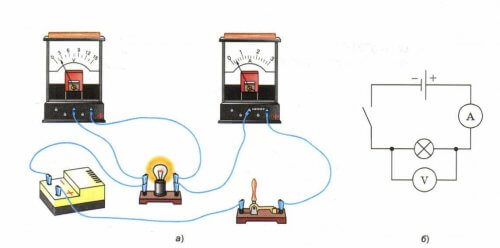

To use an ammeter for measuring amperage, you need to have certain skills and know how to include an ammeter in a circuit to measure amperage.

An ammeter, like a multimeter, is included in an open circuit. It is important to understand that alternating current is the most dangerous, therefore it requires a serious attitude to electrical safety. When you turn on the ammeter in the circuit, supply voltage and connect the load, the current in the circuit will be indicated on the display or the ammeter board.

Current measurement examples

To understand the principles of measuring current strength in various electrical appliances and circuits, the following are device options and methods for measuring current strength.

Electric motor

Current measurements in the motor windings are carried out to check for short circuits, faults and to set up the correct motor control algorithm. Since the current is in three-phase induction motor is identical in each phase, it is enough to connect one ammeter to one phase to check its consumption.

To diagnose each of the windings, the current in each phase is measured, and if it differs in each phase, then an inter-turn circuit is possible in some of the windings, and if there is no current in one of the phases, either a break on the line or a break in the winding . If there is current in one of the phases but it is less than in the other two, poor contact is possible in the Brno or in switching devices.

With a single-phase electric motor, everything is simpler: the current is measured in a single phase. But you need to keep in mind that the maximum current strength of the ammeter is limited and usually does not exceed 5A, therefore, for high currents, use current clamps or other circuits with current transformers and an ammeter.

Welding machine

In order to understand which electrodes to use and in what mode to perform welding work, it is possible to measure the current strength on the output wire of the welding machine under load.The measurement is carried out similarly to other devices, including an ammeter with a transformer in the circuit on the welding inverter (there are also old models of ammeters with the ability to measure up to 200 A) or using current clamps.

Batteries & Batteries

In everyday life, it is often necessary to measure the current of an electrical appliance on batteries (batteries may include crowns, finger batteries, and other batteries). It is important to understand that it is impossible to simply connect a multimeter or ammeter to the source, because the current is measured only under load.

As a load, you can stop on an incandescent lamp or on resistor or will be included in the circuit of the device itself. To measure, you need to select the required mode on the multimeter (for measuring direct current), correctly connect the terminals to the device and on the circuit. In this case, on the screen we get the desired value for the load that is connected to the battery.

Conclusion

As you can see, there are only two ways to measure current:

- Using an ammeter or multimeter - in this method it is important that the device can withstand and its measurement limit was calculated on the measured current strength. The disadvantage of this method is that it is necessary to break the circuit. Then, when measuring on the board, you will have to cut the track, and when measuring the consumption of devices, cut their cable and select one of the cores, or disconnect one wire from the device and include a measuring device in its circuit.

- With the help of clamp meters. Often this method is used to measure alternating current, but modern industry produces current-measuring clamps for direct current, the principle of operation of which is based on the Hall effect (only such clamps are expensive - cost from $ 50). A convenient way is that you do not need to break the circuit - you only need to put ONE core in the pliers and the current in the circuit will be displayed on the screen (or the arrow will jump if the device is pointer).

There are also combined methods when the measuring device is not designed for the measured value - you can use a current transformer. For example, direct-connected electricity meters cannot always measure large currents to account for electricity. Then they are connected not directly, but through a current transformer.

Now you know how to measure the current strength in a direct and alternating current circuit. We hope that our instructions and examples helped you understand the issue. If something remains unclear, ask questions in the comments under the article!

Related materials: