What is dielectric strength?

Physical meaning

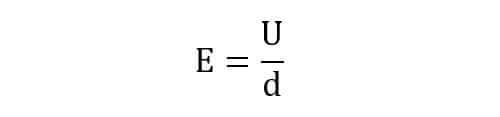

The electric field strength increases with increasing voltage between the conductors, it can be a plate of a capacitor or cable core (in an individual winding), at some point an insulation breakdown occurs. The value characterizing the tension at the time of breakdown is called electric strength and is determined by the formula:

here: U is the voltage between the conductors, d is the thickness of the dielectric.

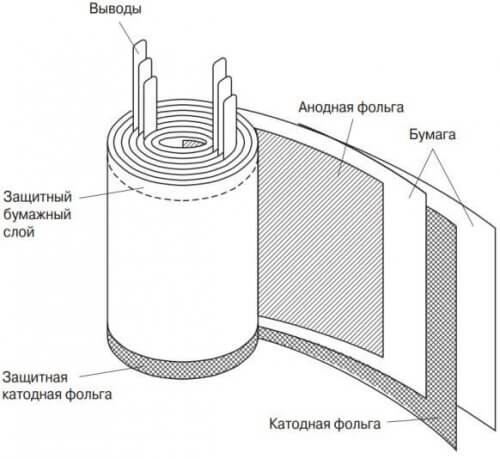

Dielectric strength is measured in kV / mm (kV / cm). This formula is valid for flat conductors (in the form of tapes or plates) with a uniform layer of insulation between them, as, for example, in a paper capacitor.

Short circuit in electrical apparatus and cables occur precisely because of the breakdown of insulation, at this moment arises electric arc. Therefore, dielectric strength is one of the most important characteristics of insulation. The requirements for the dielectric strength of the insulation of electrical equipment and electrical installations with a voltage of 1 - 750 kV are described in GOST 55195-2012 and GOST 55192-2012 (test methods for electric strength at the installation site).

Short circuit in electrical apparatus and cables occur precisely because of the breakdown of insulation, at this moment arises electric arc. Therefore, dielectric strength is one of the most important characteristics of insulation. The requirements for the dielectric strength of the insulation of electrical equipment and electrical installations with a voltage of 1 - 750 kV are described in GOST 55195-2012 and GOST 55192-2012 (test methods for electric strength at the installation site).

Types of Breakdown

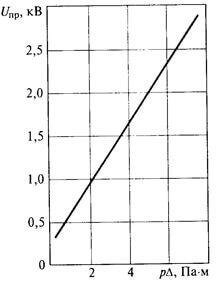

In homogeneous dielectrics, several types of breakdown are distinguished - electric and thermal. Also exists ionization breakdown, which is a consequence of the ionization of gas inclusions in a solid dielectric. The dielectric strength is largely dependent on field heterogeneity and the occurrence of gas ionization processes (intensity and nature) or other chemical changes in the material. This leads to the fact that the breakdown in the same material occurs at different voltages. Therefore, the breakdown voltage is determined by the average value according to the results of numerous tests. The dependence of the gas electric strength on the density (pressure) and the thickness of the gas layer is expressed by the Paschen law: Uetc= f (pA)

Gas and insulation

It would seem, how is ionization of gases and insulation of electrical equipment related? Gas and electricity are connected in the closest way, because it is an excellent dielectric.And therefore, a gas medium is used to isolate high-voltage equipment.

As dielectric used: air, nitrogen and gas. Elegaz is sulfur hexafluoride, the most promising material in terms of electrical insulation. For distribution and reception of high-voltage electricity, more than 100 kV (removal of power plants, reception of electricity in large cities, and so on), complete switchgears (GIS) are used.

The main area of application of SF6 gas is precisely the switchgear. Gas, in addition to being used as electrical insulation, can occur during operation of oil-filled cables (or cables with impregnated paper insulation). Since cyclic heating and cooling of the cable occurs as a result of the passage of voltage of different sizes.

The term “thermal degradation” is applicable to cables with impregnated paper insulation. The pyrolysis of cellulose produces hydrogen, methane, carbon dioxide and carbon monoxide. During aging of the insulation, the resulting gas formations (with increased voltage) cause an ionization breakdown of the insulation. Just because of ionization phenomena, power cables with insulation made of oil-soaked paper (with viscous impregnation) are used in power lines with voltages up to 35 kV and are less and less used in modern energy.

Reasons for the decrease in dielectric strength

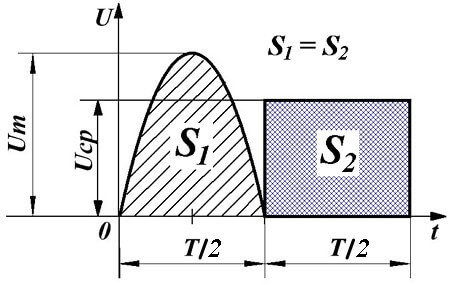

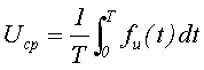

The most negative effect on the dielectric strength of an insulation is exerted by alternating voltage and temperature. With alternating voltage, that is, voltage that changes from time to time, for example, the power plant issues 220 kV to the line, due to a technical malfunction or scheduled repair, the voltage value is reduced to 110 kV, after the repair it becomes 220 kV again. This is an alternating voltage, that is, changing over a certain period of time. Alternating voltage is quite common. The average value of this voltage is determined using the graph:

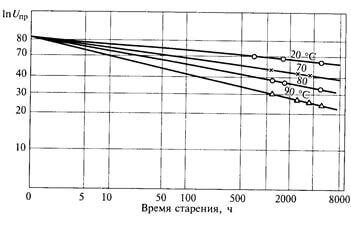

The heating temperature of the cable, due to the flow of electric current, significantly reduces the life of the conductor (the so-called aging of the insulation occurs). The dependence of the breakdown intensity at different temperatures is shown in the graph:

The heating temperature of the cable, due to the flow of electric current, significantly reduces the life of the conductor (the so-called aging of the insulation occurs). The dependence of the breakdown intensity at different temperatures is shown in the graph:

Electric strength of power cables

The most demanding electric strength industry is probably cable products. The main type of cables used in power engineering (designed for rated voltage up to 500 kV) are oil-filled paper-insulated cables.

Moreover, the higher the rated voltage for which they are designed, the higher the weight of the cable. Oil is used as impregnation degassed and low viscosity (MN-3, MN-4 and analogues). An increase in oil pressure leads to an increase in the dielectric strength of oil-paper insulation. Cables with a pressure of 10-15 atmospheres are used at high tension, the strength value reaches 15 kV / mm.

In recent years, oil-filled cables have been superseded by cross-linked polyethylene cables (SPE cables). They are lighter, easier to operate, and the service life is the same. In addition, SPEs are not so sensitive to temperature changes and do not need additional equipment, such as oil compensating tanks (to compensate for excess oil at different pressures). Cross-linked polyethylene cables are much easier to install, terminations and couplings are easier to maintain.

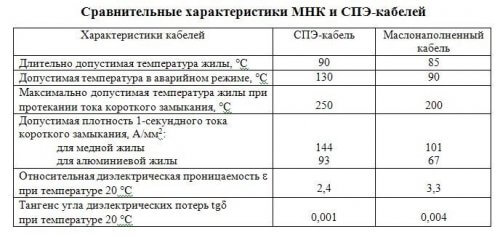

The whole world is developing SPE cables (XLPE cables), this has led to the fact that such conductors are already noticeably better in their parameters than oil-filled cables:

The only drawback of SPE is intensive aging, however, numerous studies of all world manufacturers slowed down this process. The so-called triings are no longer the causes of breakdown of insulation.The growth of energy consumption in the modern world stimulates the development of not only sources of electricity, but also cable products and switchgears. Studies on the electric strength of insulation are the main focus in power engineering.

The only drawback of SPE is intensive aging, however, numerous studies of all world manufacturers slowed down this process. The so-called triings are no longer the causes of breakdown of insulation.The growth of energy consumption in the modern world stimulates the development of not only sources of electricity, but also cable products and switchgears. Studies on the electric strength of insulation are the main focus in power engineering.

Related materials: