What are the undergrowths?

Production material

To begin with, let's look at what the undergrowths are made of and where each variety is used. So, today there are 2 main manufacturing materials:

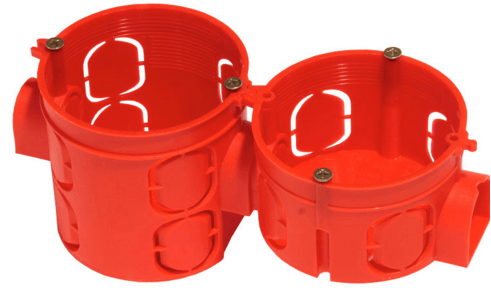

- Plastic. More popular, it can be non-combustible, due to which the undergrowth can be installed in a wooden wall (for example, in a lining or in a bar).

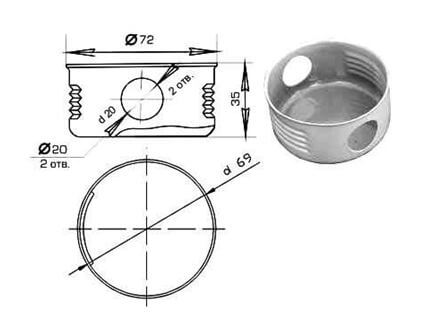

- Metal. Metal products are increasingly fading into the background. Previously, they were used to prevent the spread of flames, but due to the fact that the metal conducts electric current, for the sake of safety, this type of undergrowth loses its popularity.

- Wood. Wooden linings can be used for installation of open wiringwhen the outlet is installed directly on the wall. This type of performance also lost its popularity, but was previously used often.

Design Features

The next difference in the rosettes is a feature of the design itself. There are plastic glasses for installation in drywall, as well as concrete. The main difference between them is the presence of special presser feet, which in hollow walls (usually plaster) can reliably fix the glass. These struts are as follows:

Conventional plastic sockets are not different in design from iron ones and can be used not only for installation in concrete, but also for brick, aerated concrete, and also foam blocks. The fixation of such products is carried out by applying a layer of alabaster to the prepared hole.

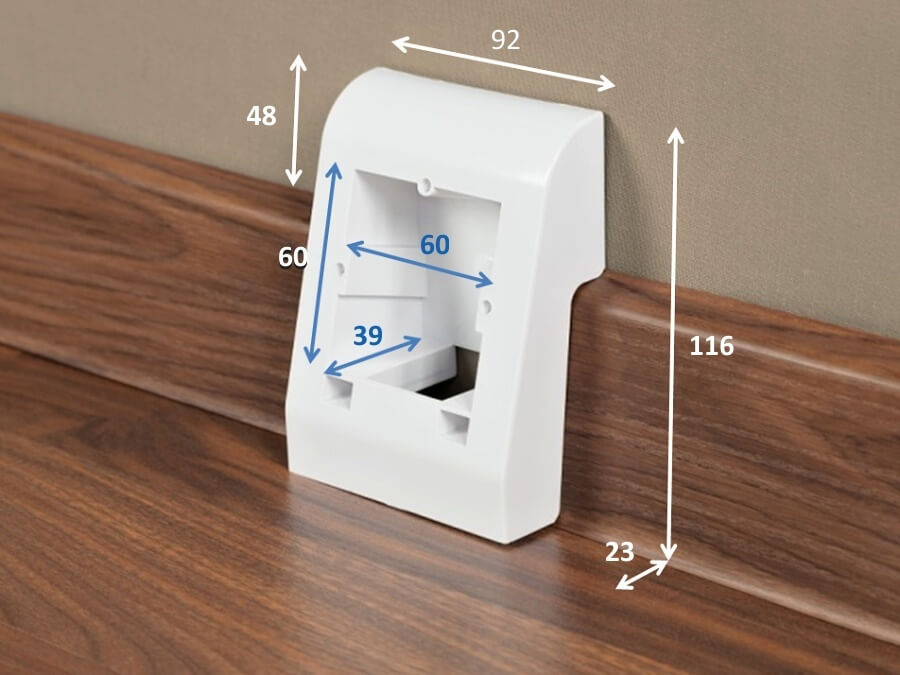

In addition, the sockets are open and hidden installation type. The former are most often used for mounting on the baseboard, if necessary baseboard wiring. Hidden undergrowths were discussed above (ordinary glass, with or without ears).

In the form of mounting boxes (I can also call them that) they are divided into round, square and oval. Most often they use a round type of execution, but sometimes it becomes necessary to use square products (they are a bit more capacious). Oval sockets are needed so that you can simultaneously plug in a double outlet (or 1, but with a light switch).

Here you should talk about composite structures that have connectors, thanks to which you can assemble up to 5 glasses in one structure, which is convenient if you decide install the outlet block in the wall. Photo of a block view of mounting boxes:

Well, the last difference between the products is the depth of the glass itself.There are narrow, standard and in-depth undergrowths. For different conditions, each individual type of housing is used. For example, deep boxes are used if it is decided to carry out electrical wiring without junction boxes. In this case, the glass itself will serve as a distribution box.

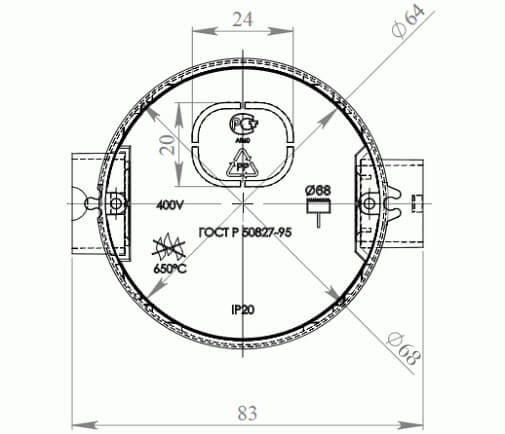

Typical sizes

Well, the last thing I would like to talk about is what are the sizes of undergrowths. The standard dimensions are 68 by 45 mm, but keep in mind that the inner diameter will be 65 mm and the depth 40. For narrow mounting boxes, the depth can be 25 mm, but the dimensions of recessed products can reach 80 mm. The diameter can also vary and not be 65, but 60 mm, which is in demand in some cases.

The dimensions of the square sockets differ, depending on the manufacturer. Most often they use a size of 70 * 70 mm, however, there may be 60 * 60, as shown in the photo below:

Finally, we recommend watching a useful video on the topic:

So we looked at what types and sizes of undergrowths are. As you can see, for your own conditions you can choose the right option from a wide range of products!

Similar materials:

Hello. I have such a question, in the video you say that you often work on a fine repair and therefore, in order not to spoil the wall finish, drill a hole in the size of the socket and fasten it to the screws, and how then you lead the wire to the outlet without spoiling the finish.

😂😂😂

Good afternoon! Advise the 32A power socket for the stove, which is part of a regular socket (for a 16A socket). To install a semi-deep power outlet for the stove! I don’t want to bomb the wall ...