What are VL insulators and what are they for?

Insulator Specifications

An electrical insulator is a product designed to fasten a wire, cable or bus to a supporting structure of a power line and prevent its breakdown to the ground. They come in many forms and are made from dielectric materials - porcelain, glass and polymers.

Since the electrical purpose of the insulators is to provide insulation of the conductor from the supporting structure, the main characteristics are:

- Dry discharge voltage is the voltage at which a spark discharge occurs on the surface in its dry state under normal environmental conditions.

- Wet voltage is the same, but in the rain, if its jets hit the insulator at an angle of 45 degrees. The rain force is 5 mm / min, the specific volumetric resistance of water is 9500-10500 Ohm * cm (at 20 ° C). Since water conducts electric current, the wet discharge voltage is always lower than the dry discharge voltage.

- Breakdown voltage is the voltage at which the breakdown of the insulator body occurs between the rod and the cap (for suspended products). The rod and cap are electrodes.

Design

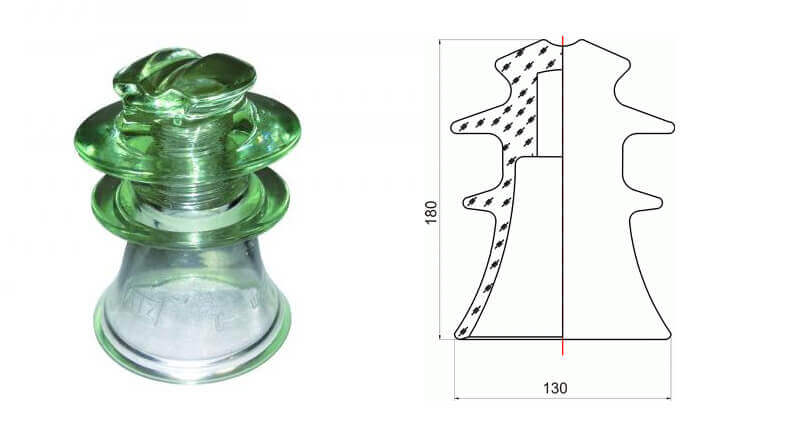

Structurally, all electrical insulators differ in the ways of fastening to the supporting structure and fastening the cable. The main objective of this product is to prevent electrical discharges, for this they are performed in the form of plates or rods with ribs. These ribs are needed so that the discharge develops at an angle to the field lines of force. In the figure below you see examples of typical products of different shapes and designs:

Material difference

To consider the classification of species and types of insulators, you first need to understand how they are distinguished. So, first of all, they are classified according to the material of manufacture:

- Porcelain.

- Glass.

- Polymer.

Porcelain can be called classics, such were used before even with outdoor wiring in houses. Usually they are white, but can be other colors. Such can be seen on various electrical installations. The advantage is that they withstand large compression loads, have good dielectric properties.

However, they beat and break. Hence the need to regularly check their integrity, and often for this you have to turn off the electrical system and wipe oil, dust and other contaminants from them. Also a problem is their heavy weight.

Glass, although they are afraid of shock, but to control their integrity, a visual inspection is enough, which can be done without disconnecting the voltage. Currently, in overhead power lines, as suspension insulators, they displace ceramics, including because they weigh less, and also cheaper in production.

Polymeric are used indoors, rarely on the street, as an exception. You can sometimes see support insulators made of polymers on a 10 kV overhead line or other medium-voltage voltages, but rarely, or on irresponsible lines. This is due to the fact that over time and under the influence of UV radiation, they age, the internal structure decays and their electrical and mechanical characteristics deteriorate.

However, for equipment that is available for regular maintenance and repair, they are often used. For example, it can be busbar insulators in transformer substations and distributors.

Types by design and purpose

By design, there are three main varieties of VL insulators:

- pin;

- suspended linear;

- basic and through passage.

Pins are linear insulators. Used in power lines up to 35 kV. Including on the lines of 0.4 kV. This type of execution is one-piece, it has a groove for securing the wires and holes for mounting on the yokes, hooks, pins.

Interesting: on overhead lines from 6 to 10 kV, single-element insulators are used, and on 20-35 - from two elements.

Overhead are used on high-voltage overhead lines with a voltage of 35 kV and more. They are of two types supporting (rod) and tension.

Stretch plate insulators work in tension and hold the line on a support, mounted at an angle. Structurally, they are made in the form of a porcelain or glass plate. In the lower part, a rod with an expanding hat usually protrudes. On top is a metal cover with a hole of a special shape, such that it can be used to fix the lower shaft. Thus, unification occurs and you can garland as many insulators as you need to achieve the desired rated breakdown voltages. Such a garland turns out flexible, it keeps power lines on a support.

Suspended rod insulators are installed on the intermediate supports. They are made in the form of a support rod, at its ends metal parts for fastening to the support and wires. They are installed vertically and the wire rests on them - this is the main difference from the previous ones. They also differ in that the tension insulators withstand more weight, so they can be used on supports located further from each other.

Interesting: in critical areas and to increase the reliability of installation of power lines, double garlands of tension insulators can be used.

Support and bushing insulators are already station, and not linear. This type is so called because it is used inside power plants and transformer substations. Made from polymers or porcelain. The supporting ones are used for attaching conductive busbars to grounded structures, for example, the transformer case or inside the input and distribution switchboards.

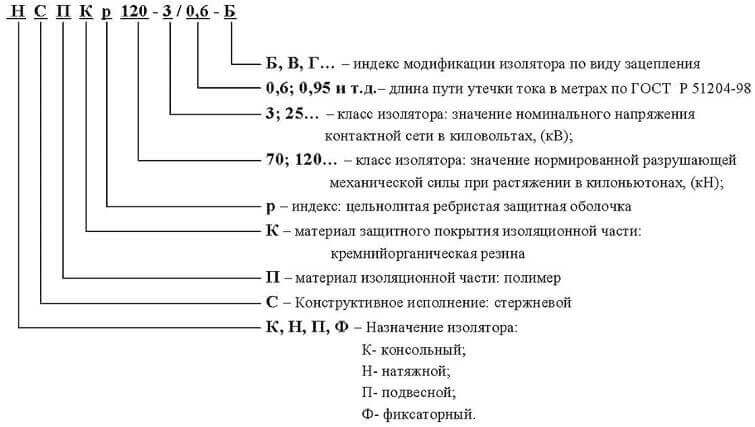

The marking of insulators of all varieties is similar, usually it contains information about the type of product and the rated voltage of the line, for example:

In order to pass a cable or bus through the wall, bushings are used. This type of product with a hollow body, in which the live part is located. To increase the insulating properties, it may additionally have an oil barrier or an oil pad. This type of insulator allows you to lay a line up to 110 kV. There are other types - without a current path inside, just a dielectric hollow cylinder with a hole that is worn on the cable.

This is where we end our article.Now you know what insulators are for overhead power lines and where each version is used!

Related materials: