How to protect cables and wires from UV

Detached buildings, cottages or buildings are connected using cable products. They can be laid underground, but it is costly. More often use an air connection. It should be borne in mind that not every cable can be used for outdoor use. They must be designed to operate in adverse conditions. For example, ultraviolet radiation adversely affects cable insulation. In this case, the damage does not occur immediately. It can be determined only after a few years. The insulation becomes brittle and crumbles. In some cases, it softens, resulting in current leaks and short circuits. In this article we will look at how to protect the cable from ultraviolet radiation, or as it is also called, from solar radiation.

Sun exposure to cable

Ultraviolet radiation acts gradually, it leads to a deterioration in the state of the integumentary insulating layer. Under the influence of sunlight, accelerated aging of the surface layer occurs. As a result, insulation changes its characteristics. Depending on the material, it becomes:

- Tough. When exposed to mechanical stress, it cracks and crumbles. This is especially noticeable on the insulation of the cable cores.

- May change color or become sticky and lose its insulating properties.

Moreover, these changes occur first only in the surface layer. Depending on the light intensity, ultraviolet changes the physico-chemical characteristics of the insulation. Cracks appear and leakage currentresulting in a breakdown. This is typical when exposed to solar radiation and ozone - the strongest oxidizing agent.

The figure below shows the result of its long-term effect on insulation.

Stable Conductor Brands

In order for the cable to serve for a long time, you need to know what cable products can be used and how to protect it from solar radiation. The industry produces several types of cable that can be used to connect consumers.

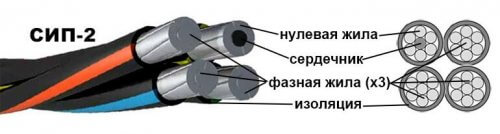

Entering into a private house or cottage from a support is in most cases carried out by air. To do this, use a self-supporting insulated wire (SIP).

The insulation is made of cross-linked polyethylene, which is not affected by ultraviolet. Current-carrying conductors are made of aluminum. Connection is made using a bolted connection.

The insulation is made of cross-linked polyethylene, which is not affected by ultraviolet. Current-carrying conductors are made of aluminum. Connection is made using a bolted connection.

Less commonly used for air connection cable VVSG. The cable has double insulation, which has UV protection.

The most common cable is used to connect a shed or bath. VVGng-LS. The connection of wires SIP with VVGNG-LS perform piercing clamps.

Cable protection

The action of ultraviolet radiation also affects the surface insulation of wires.

If it is necessary to connect a separate building, resort to additional protection:

- If the wiring is made along the wall of the building, then it must be mounted on the north side of the building. Be sure to cover with visors or gutters. They protect not only from sunlight, but also from falling from the roof of snow, icicles and rainwater.

- A cable is suspended between buildings on a steel cable, and for protection from solar radiation use a corrugation or a metal pipe.

In air, wires are placed in a pipe if there is a possibility of mechanical damage.

The industry produces gray corrugation, it is intended for indoor use, and is made of PVC, it is unstable to UV radiation. It can not be used. But there is a black PVC corrugation that is resistant to ultraviolet (check this fact in the product documentation from the manufacturer). There are other corrugations designed for outdoor use - from high and low pressure polyethylene and is selected depending on the purpose. Such pipes are painted black or red, but do not focus on the color. They are well resistant to external influences and can be operated in a wide temperature range from -400 up to +450C, and resistant to destructive solar radiation.

In order not to make a mistake with the choice, it is necessary to study the characteristics of the product. Before purchasing pipes, it is recommended to study the features of the corrugation. This can be done by reading the article on the site - https://our.electricianexp.com/en/vidy-i-razmery-gofry-dlya-kabelya.html.

Often used to connect the power supply of detached buildings metal hose. It protects cable products from exposure to light, precipitation in the form of snow sticking, icing and provides additional mechanical protection. But it is short-lived, susceptible to corrosion, therefore, when using it, this feature should be taken into account.

Insulation protection methods

Even if you lay the line in a corrugation or metal hose, then when using the VVGNG-LS cable to connect consumers outdoors, there is a problem with the inner insulation of the cores. It is less resistant to ultraviolet radiation and is destroyed in a short period of time. We are talking about the cut ends of the cable at the connection to the trunk SIP.

Therefore, a cut cable requires additional protection from sunlight. Sealed boxes are used for this. But they can not be used everywhere.

In addition, you can use shrink "gloves." The industry produces them in different diameters and configurations. The figure below shows the "gloves" for a voltage of 220/380 V.

Gloves can be replaced shrink tube with glue composition. It is put on each core and the end of the cable. In this case, take into account that the “glove” and the tubes should be black. They are able to reliably protect insulation. from exposure destructive radiation.

Extra UV protection

You can protect the insulation layer with tape. Cut wires are completely wrapped with electrical tape. Closing and the end of the outer insulation, which is in sunlight.

However, you should be aware that you can only use special, for example, 3M Scotch 780 or 3M Scotch 33, black electrical tape and provides protection from ultraviolet radiation. I note that not all black ribbons are resistant to ultraviolet.

Conclusion

Correctly choose cable products will help article - https://our.electricianexp.com/en/kabel-dlya-prokladki-na-ulice.html

And when connecting detached buildings, it is necessary to take into account operating conditions and characteristics of materials:

- SIP wires can be mounted without additional UV protection. The manufacturer guarantees long-term operation in the open air without damage to the insulation, since it has a steel core, then a supporting metal cable is not required. However, the industry produces SIP-4.It represents a pair system. The main difference is the absence of a supporting core and a neutral wire. If you use this type of wire, then it should be tied to a steel cable. The figure below shows SIP-4.

- The common cable VVGNG-LS, must be protected with a corrugation or metal sleeve so that it is not damaged by ultraviolet. To avoid breaks from sticking snow or icing, it is imperative to hang it from a bearing steel cable.

So we looked at how to protect the cable from ultraviolet radiation. We hope that the information provided helped you find the right protection option for your conditions!

Related materials: