Why do you need to re-ground the VLI?

Repeated grounding of VLI is a deliberate connection of the neutral wire to the grounding device in electrical installations up to 1 kV, which may be in electrical communication with the grounding device of the power source. VLI is an overhead line on supports made of reinforced concrete or wood with self-supporting insulated wires (SIP) Below we will tell readers of the our.electricianexp website how to properly re-ground overhead power lines and what it is for.

Types of supports

Wooden

Wooden poles are currently used in a limited way, mainly in sparsely populated areas. They have advantages such as low manufacturing cost and ease of installation, light weight, high resistance to stress. In addition, wood is a good dielectric, which increases the safety of operation. The disadvantages of wooden supports include the need to select logs for one overhead line with the same diameters to ensure the same load distribution, high susceptibility to mechanical damage and rapid wear of wood during operation. To eliminate the negative environmental impact and reduce rotting processes, wooden supports are impregnated or coated with special compounds.

They make supports of coniferous wood. The diameter of the logs and the length is selected according to the class of support. The classification of the supports is made in this way, a log of a certain diameter of the upper end and a certain length should have an appropriate weight or volume. Wooden poles can be class L, M or S

Supports for overhead lines up to 1 kV must have a diameter of at least 14 cm. The height of the supports is from 6 to 13 meters. Depending on the class of wood and its cubic capacity, supports can weigh from 180 to 350 kg.

Reinforced concrete

Reinforced concrete supports are more durable and stable than wooden ones. The term of their wear is significantly longer than that of wooden poles, so they are most common in the construction of overhead lines of different voltage levels.

Reinforced concrete supports are made of reinforced concrete, before manufacturing they are calculated depending on what role the support will play in the overhead line. The requirements for load distribution are established by GOST I PUE.

Reinforced concrete supports are classified in the following order:

- special - designed for certain conditions: climatic, when crossing over obstacles, at intersections of overhead lines and others;

- end - are installed at the end of the overhead line;

- angular - use on overhead lines;

- anchor - carry out the tension of wires in straight sections;

- intermediate - support, but do not pull the wires.

Reinforced concrete supports are used in all overhead lines - both with ordinary wires and with self-supporting insulated wires.

The photo below shows the appearance of a reinforced concrete support.

The following reinforced concrete structures are used:

- CB 105;

- CV 110;

- CB 95;

- CV 85.

In order to carry out secondary grounding of the PEN conductor, reinforcement is welded on both sides of the support. This is done to fulfill the requirements of the EMP (clause 2.4.40, see Chapter 2.4): "The PEN conductor should be connected to the reinforcement of reinforced concrete struts and struts."

Re-Grounding Purpose

Re-grounding the VLI is necessary in order to ensure normal electrical safety during the operation of the VL. According to clause 2.4.38 of the PUE “Grounding devices must be made on the overhead poles for re-grounding, protection against lightning overvoltages, grounding of electrical equipment installed on the overhead poles. The resistance of the grounding device shall not exceed 30 Ohms. "

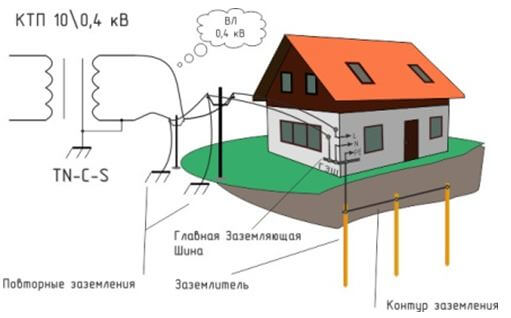

If a transformer substation with dead earthed neutral, in order to ensure the required electrical safety, it is necessary to create an electrical connection with grounding throughout the system. For supports, the ground wire is re-grounded - this ensures reliable connection of the PEN conductor with the grounding device. The scheme is as follows:

The PUE indicates that re-grounding the VLI means immersion in the ground of a PEN or PE conductor in an overhead electric line with insulated wires.

Important! The re-grounding circuit is carried out on the backwater without an input device or an input shield (VSC). It attaches to the introductory machine or to the joint circuit breaker.

The protective and working neutral wires are connected at the top of the reinforced concrete pillar (reinforced concrete pillar) to the reinforcement outlet. If there is a strut post, then it is necessary to attach to it, and not just to the main one.

The photo below shows how to re-ground the VLI of the main conductor using piercing clamp on a checkpoint, without a tap. It is necessary to carry out this on every third support of the overhead line and on the pole that leads to the residential building.

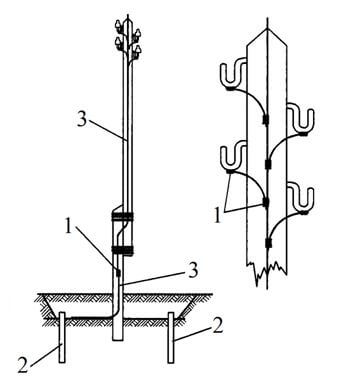

On supports during installation, an earthing descent of wire or rolled steel can be made. It may also be absent. The figure below shows the construction of a support with grounding descent.

- 1 - welding spot;

- 2 - grounding conductors;

- 3 - descent.

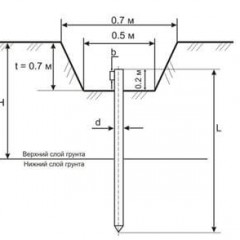

As a rule, it is made of metal wire. All this is attached to the pin electrode, which is driven into the ground. If the wire is larger in diameter than 6 mm, then it is desirable that it be made of galvanized metal, and if less than 6 mm - of ferrous metal with an applied anti-corrosion agent.

According to the rules of electrical installations, if the PEN conductors were re-earthed on a wooden structure, then all the pins and hooks of the metal support must be fully earthed. If a repeated grounding circuit is not organized on a wooden or reinforced concrete pillar, then nothing needs to be done (PUE 2.4.41).

Electrical equipment made of metal, which is located on supports, must be earthed by individual wires. These are equipment such as HV panels, lightning protection or high voltage protection. In the case of a transformer with a grounded neutral, the resistance of the secondary ground electrode must be 30 Ohms or less.

Please note! For private housing, the re-protection of PEN conductors of VLI does not exempt from the installation of a special grounding circuit. About, how to make grounding in the house with your own hands, we told in the corresponding article!

Useful Tips

If it is necessary to re-ground the VLI from a transformer substation to a residential building at a distance of 800 m, it should be performed in the following places:

- on overhead poles, which are located near the transformer substation and near the house;

- on anchor poles of overhead lines;

- on a support with a distance of 100 meters from the main support, having grounding.

We also recommend that you watch a video that shows how to re-ground, or rather, drive the pins into the ground without any problems:

Useful on the topic: