Characteristics of the PPV wire

Labeling Explanation

All brands of wires, as well as cables and cords, are marked in a set of corresponding alphanumeric characters. The cable product labeling system is made in accordance with the following description:

I II III IV V — VI

- The material of which the live part is made, if the letter A is indicated at position I, the core is made of aluminum. In the absence of an alphabetic symbol, the core is made of copper.

- A symbol consisting of two letters, the first of which will be necessarily P, which means a wire, the second will indicate its type. In this case, it’s flat.

- Literal designation of the shell material. B - polyvinyl chloride (PVC).

- Indicates the number of cores.

- Cross section

- Maximum allowable voltage.

Labeling example: PPV 2x4-380 - flat wire, two-core, core section 4 mm2, network voltage 380 volts.

Design and scope

For the installation of electrical wiring of lighting networks and power systems, PPV wire is most widely used. It is suitable for operation in networks with alternating voltage up to 450 volts and a frequency of up to 400 hertz. In DC electric systems, PPV can be operated with an operating voltage of up to 1000 volts.

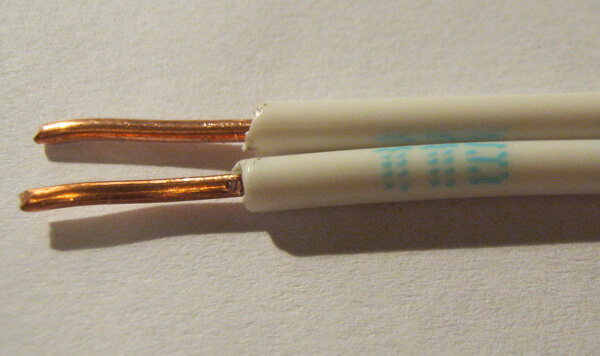

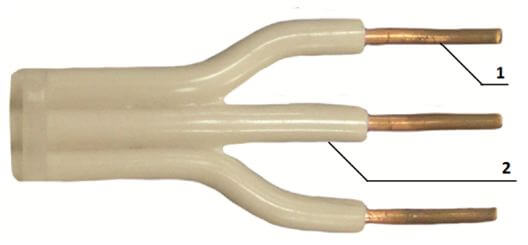

PPV wire is a technical product, the basis of which is two or three conductive conductors, with a cross section of 1.5 to 4 mm, made of copper. Seamless copper wires (1) are laid in one plane and covered with a polyvinyl chloride (PVC) sheath (2). The color of the shell is not regulated by the requirements of regulatory documents, therefore, coloring can be done at the discretion of the manufacturer.

Appearance of the conductor:

The properties of the polyvinyl chloride sheath determine the purpose of its use for stationary and non-flexible laying, with the recommended placement in the cavity of pipes and channels of building structures or on trays.

Specifications

The main characteristic of a wire is its ability to hold a current load without time limits. The table of the sections of the PPV and their compliance with the current load:

| Core section (mm2) | Two-core | Three-core |

| 1,5 | 18 Amp | 15 Amp |

| 2,5 | 25 Amp | 21 Amp |

| 4 | 32 amperes | 27 Amp |

During operation of the wiring, special attention is paid to the current load on the wire, it is strictly forbidden to exceed the permissible current.The PVC sheath does not support the combustion process, however, when exposed to high temperatures, it loses its electrical insulating properties, which can cause its destruction and shorting of current-carrying conductors. The temperature of heating the cable when receiving a load should not exceed 700C. Based on the current characteristics, in accordance with the data in the section table, the permissible maximum current load on a PPV wire for lighting networks where a two-wire version is used is 32 Amperes. In power networks for a three-wire conductor, the effective current value should not exceed 27 Amps.

In accordance with the requirements of electrical safety, insulation resistance at ambient temperature within 200C, must be at least 1 megohm.

It should be noted such technical characteristics of PPV as the ability to operate without restrictions at low temperatures, reaching -500C, and one hundred percent environmental humidity. However, it should be borne in mind that work on laying the wire can be carried out at a temperature not lower than -150C. During installation, the radius of bending should be maintained, which should not exceed 10 diameters.

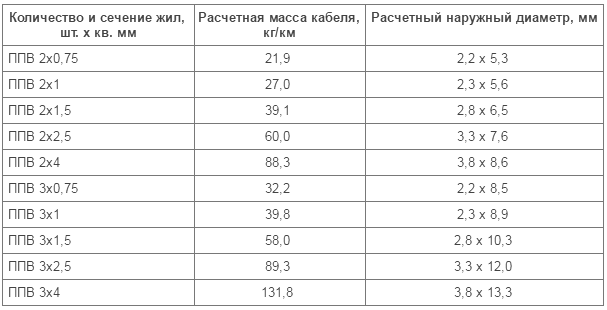

As for the estimated mass and outer diameter, the values are provided in the table:

The service life of the PPV wire, at which all technical specifications are preserved, is 15 years, subject to the conditions of use. The manufacturer of the products provides a 2-year warranty.

You can learn more about this brand of conductor from the video:

So we examined the technical characteristics of the PPV wire, as well as its scope and cross-section. We hope the information provided was useful and interesting for you!

We also recommend reading: