Choose a screwdriver - what to look for?

Pay attention to the design

Typically, a screwdriver consists of three elements: a tip, a shaft and a handle. You can choose a solid tool, in which the shaft passes completely through the body. And you can choose a composite model with bits. This choice is considered more practical, since the set contains various nozzles. Depending on the design of the tool, you can change either one bit or a bar.

The choice of material of the handle should be careful, as it must be durable and comfortable. As a rule, a material such as plastic, wood or rubber is used for it. A screwdriver with a plastic handle is considered popular because it can be used under any circumstances and conditions, it is easy to clean from various kinds of contaminants. A convenient and good handle is considered the option with the presence of rubber inserts, since such a coating will not rub calluses.

You need to choose a rod from a high alloy strong steel that will be strong and resistant to corrosion. High strength tools provide such steels as chrome vanadium and chromium molybdenum. The sting of such a material is not afraid of the action of oils, moisture or other abrasive materials. The correct choice of the rod depends on its strength, length, shape and diameter. According to GOST, the strength of the rod should range between 47 and 52 HRC. If the strength of the rod is less than 47, it can bend, and if more than 52, crack.

The choice of the tip requires special attention and depends on which heads on the screw or the slots on the screw (it is advisable to choose a screw). A Phillips screwdriver is considered more popular than a flat head screwdriver. Also, the tip can be in the form of a six-pointed star.

A screwdriver with a magnetized bat is able to hold minor details on the tip, so it is indispensable when working with small fasteners. The color of the tip must be chosen not the same as the rod. In order for the sting (tip) to acquire greater strength, it is treated with a special tool (for example, oxidation) due to which the element becomes dark. A dark rough tip indicates that the tool has undergone an oxidized treatment. If there is no such treatment, then the sting will be glossy and will wear out quickly.

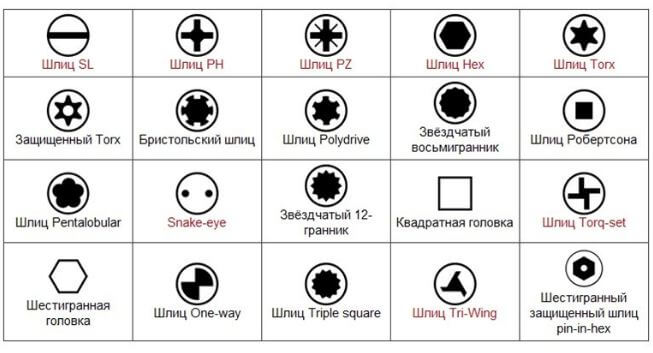

Varieties of tips

A screwdriver with a flat tip has the specified tip width, so selecting the right tool for the specific fixture is easy.The remaining digits indicate the size of the working part.

The choice of the working part, namely the sting, is a serious matter. After all, it must match the shape of the fastener. Each sting has its own designation and meets certain standards. The main and most demanded are such types of screwdrivers:

- Flat (SL). For the home - this is the necessary type of tip, since it can be used to fix door fittings or sockets with switches.

- Cross (RN). This is the most common type of device. If compared with the previous version, then such a screwdriver is better in contact with a self-tapping screw or screw, so that the force during screwing becomes greater.

- Crosswise with guides (PZ). The choice of this type is appropriate for the assembly of furniture or for the installation of a variety of structures. A slotted screwdriver PZ is used when there are four other minor recesses in the fastener, in addition to the main cross.

- Hex (HEX). The torque of such a tool will be ten times higher than the readings of a Phillips screwdriver. Such fasteners are used in automobiles, technical equipment and other elements.

- Star-shaped (TORX). It has a tip in the form of a six-pointed star. It is rarely used, since such compounds are in electronic and household appliances.

Application area

The choice of a screwdriver must be approached so that it is regularly used. This can be done correctly, provided that you know what type, in which area is popular. For example, with soured or sticky connection elements, you can use an impact screwdriver. Inside the handle of such a product there is a mechanism that, upon impact, is converted into rotational movement, thus displacing the fasteners a small distance and making the connection weaker.

It is advisable to choose a cordless screwdriver for those whose work involves the constant tightening of screws, as this will save the physical strength of the working person. This design combines the compact dimensions of a manual model and the productivity of a screwdriver. It is used for long-term work in the furniture and automotive industries. For example, install or remove a specific element in a car or assemble / disassemble furniture.

There is also a so-called tester screwdriver. The choice of such a specialized device is important for finding the phase in the electrical network. It is also called indicator, since there is an indicator in the handle of the device that lights up when you touch live parts with a tip.

There is also a dielectric screwdriver with which you can work under voltage. This type of construction is suitable for electricians.

For assembly work it is better to choose a torque model. It is used in those works where accuracy is important. To control the force of twisting, there is a special scale, as in the photo below:

If during work it often happens that you need to tighten the self-tapping screw in a hard-to-reach place, we recommend choosing a screwdriver with a flexible shaft. Its advantage is clearly shown in the photo:

We also recommend watching a video in which experts consider different versions of screwdrivers and express their opinion on how to choose the right model:

Now you know how to choose a screwdriver and which one is better for different jobs. We hope that the provided tips were useful for you and helped in choosing the right tool!

We also recommend reading: