Laying carbon fiber underfloor heating for tiles and laminate

Rod

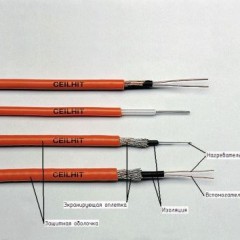

The carbon fiber rod floor is made in the form of a structure based on conductive rods made of composite material. The composition of the material includes an amorphous form of carbon, also contains graphite and silver. The photo shows a separate rod:

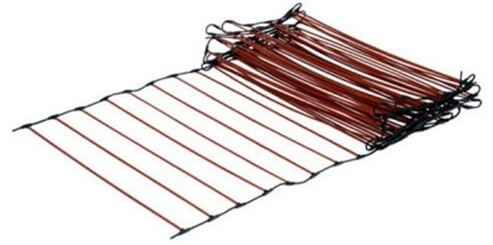

The rods of the infrared floor are connected in parallel. The connection is made by a copper stranded wire in a heat-resistant sheath. The assembled design has the form of a wire mat, which is spread on a prepared base for flooring.

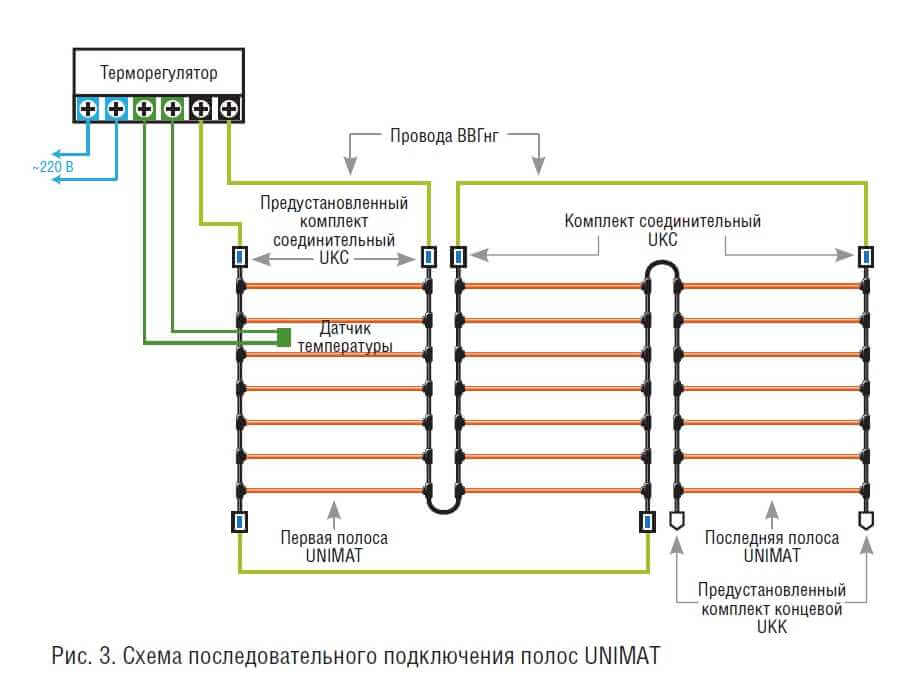

Connection diagram of elements:

Type of mat collected:

The carbon fiber underfloor heating in the rod version has a number of features that determine its advantages over other systems:

- lightness of heating elements, due to which heating does not load the building floors;

- high corrosion resistance, ensuring heating performance during the entire period of operation of the building;

- increased fire safety due to the use of non-combustible materials;

- the ability to use in rooms with high humidity;

- the ability to install almost any type of flooring;

- high reliability - if one or more rods fails (which is unlikely in itself), the system does not lose operability;

- a unique effect of self-regulation of the load, determined by the property of the used conductive material.

Self-regulation is that the carbon composite used increases the electrical resistance with increasing temperature, unlike metal conductors. This property prevents the heating elements from overheating even under conditions of poor heat dissipation (for example, when a section of the heated floor is covered by standing furniture).

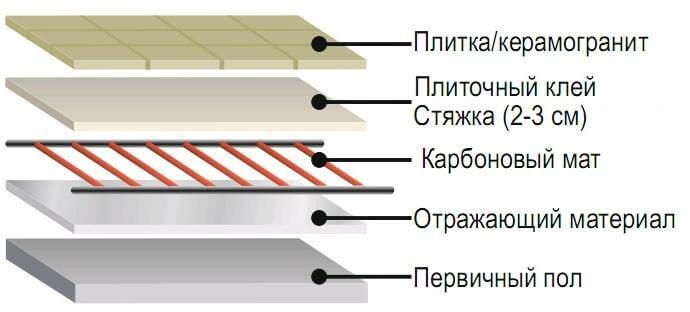

The only property of the rod system, which can conditionally be attributed to the disadvantages, is that this design must be placed in a thin screed or a layer of glue under the tile.

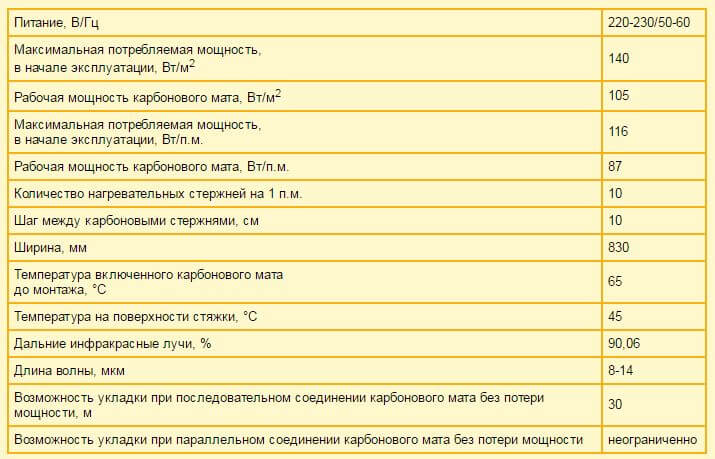

Technical characteristics of rod heating elements:

Installation of a rod infrared warm floor begins with laying a heat-insulating substrate on a previously prepared surface. As a substrate, a two-layer material is used, consisting of a layer of foamed insulation and a heat-reflecting lavsan film.This procedure will allow more rational use of electricity when heating a room. At the next stage, the mats are laid out, as shown in the photo below:

The system kit must contain instructions for connecting, according to which it is necessary to make all electrical connections. After performing these operations, it is the turn to fill the rods with a layer of screed or tile glue. It is advisable to limit the thickness of the screed to two to three centimeters. Electricity is produced after the layer of screed or glue is completely dried.

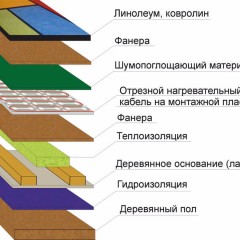

Laying scheme for tiles and laminate:

DIY assembly instructions for the infrared core floor are provided on the video:

In addition to the above-mentioned tiles, the installation of a rod heat-insulated floor can be carried out under the laminate, under linoleum, as well as under the board.

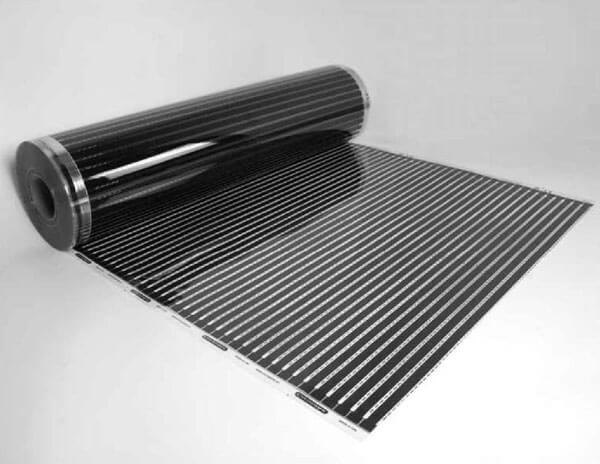

Film

The carbon-fiber film underfloor heating contains two layers of a dense heat-resistant polymer film, between which are carbon-graphite conductive tracks. Carbon conductive layer is applied using high technology nano-spraying. Tightly bonded layers of polyester prevent moisture from entering conductors and electrical contacts. The special composition of the polymer provides high mechanical strength of the structure. The melting temperature of the film is 120 ° C. The photo shows the appearance of the film version of the system warm floor:

Infrared carbon film has all the main advantages inherent in the rod analogue, but has some features:

- When laying a film floor, it is not filled with cement screed or tile adhesive, which limits its use for installation under tiles. In each case, the manufacturer's instructions should be followed.

- Installation of the film is faster and easier than the rods, if necessary, it can be removed just as quickly.

- The film thickness is less than the thickness of the core mat, which in some cases can play a decisive role in the choice of design.

In accordance with the recommendations of manufacturers, for heating a room it is enough to lay about 70% of its area with a warm floor. Having determined the coverage area, you need to calculate the footage of the material. To do this, you need to know what is the bandwidth of the selected heater. About, how to calculate the power of a warm floor, we told in a separate article.

Installation of a film heat-insulated floor quite simple. Before laying the film, a layer of a substrate reflecting heat is laid on a previously prepared smooth surface. The film is neatly laid on top. Further, in accordance with the attached instructions, the electrical contacts are connected. Then you can proceed to the flooring.

The installation instructions for the infrared carbon film are shown on the video:

The technical characteristics possessed by the rod and film infrared floor determine a wide range of its application. Such systems are used for heating living rooms, bathrooms, bathrooms. It is convenient to use this type of heating for loggias, winter gardens. The ability to quickly adjust the heating power and implement daily heating schedules of premises makes the integration of heating into the "smart home" system promising. Now you know what a carbon-fiber underfloor is, what types of systems are and how do you install heating elements with your own hands!

We also recommend reading: