Laying a film underfloor heating under the laminate and parquet board

Determined with the type of heater

We recently reviewed types of electric underfloor heating, where a little about the issue of using different heaters for tile and wooden flooring.

In the case of a wooden floor, it is not recommended to use heating mats and cable, for the following reasons:

- Electrical conductors can unevenly radiate heat, which adversely affects the wood flooring.

- Heated with an electric cable (or mat) consume more electricity, therefore, from the side of cost savings, laying a film warm floor under the laminate, again, wins.

- For infrared coating, the presence of a concrete screed is not mandatory, which can not be said about alternative options.

- The film thickness is less than a millimeter, which will save the height of the ceiling after installation. In the case of an electric conductor, due to the screed, the ceiling height can be reduced up to 10 cm.

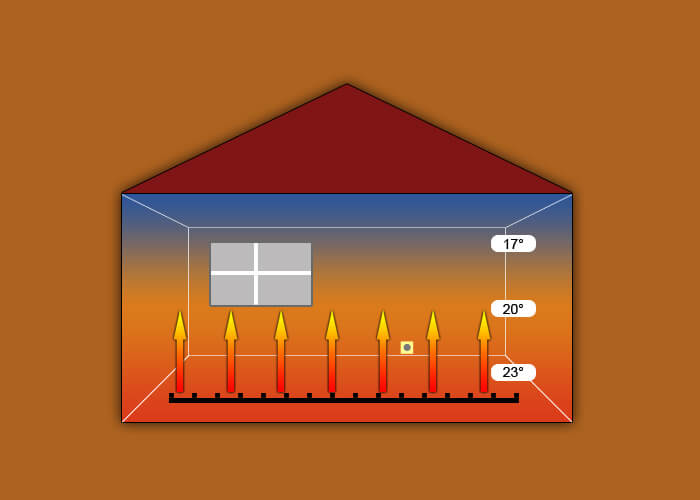

- Since the laminate has a low thermal conductivity, it is not recommended to use cable heating. This is due to the fact that the conductor first heats the screed, which transfers heat to the floor itself. As a result of such heat transfer, the efficiency is an order of magnitude lower than with infrared radiation, which immediately warms up all the objects in the room.

It is for these reasons that the installation of a film heat-insulated floor under a laminate and a parquet board is used.

We prepare all the necessary materials

At this stage, it is necessary to calculate the warm infrared floor under the laminate to determine the right amount of all materials. The calculation part is quite simple, you just need to calculate the usable area of the room and, taking into account the selected power of the heater, calculate its area.

So, in order to facilitate the perception of information, we present all the points:

- We determine the useful area of the room. It is necessary to lay the material at a distance of at least 15 cm from the wall, and it is forbidden to lay the film under heavy furniture and household appliances. Based on these requirements, we create a scheme and determine the usable area.

- Choose the power of the system. As a rule, for heating a warm floor, a coating with a power of 150 W / m is used2 (if there is no central heating) and 90 W / m2 if the house has a heating system. You can also select intermediate values based on your own conditions of use.

- We calculate the amount of film. To do this, multiply the useful area by the power that you have chosen. For example, for a room of 15 m2 without central heating, a warm floor with a power of 2250 W (15 * 150) will be required. We go to the store and buy a roll of a suitable size.

It is also additionally necessary to purchase a heater (penofol is best), foil tape and polyvinyl foam film (protects the surface of the heater from mechanical damage).

When all materials are counted and purchased, you can proceed to the installation process.

We carry out installation work

The technology for laying a film underfloor heating under a laminate consists of several stages:

- surface preparation;

- base insulation;

- flooring material;

- laminate finish.

We draw your attention to the fact that this technology is also used in the case of a parquet board, while installation is carried out according to a similar scheme!

Prepare the surface

At this stage, it is necessary to remove the old finish of the flooring, remove all debris and view the condition of the concrete screed. It is necessary that the surface is flat, without chips and cracks. Otherwise, you will have to fill in the rough screed, which will remove all defects.

It should immediately be noted that in rooms with high humidity (on an unheated loggia or in a bathhouse) it is strictly forbidden to lay the infrared coating. If the humidity is small, you also need to take care of high-quality waterproofing of the floor!

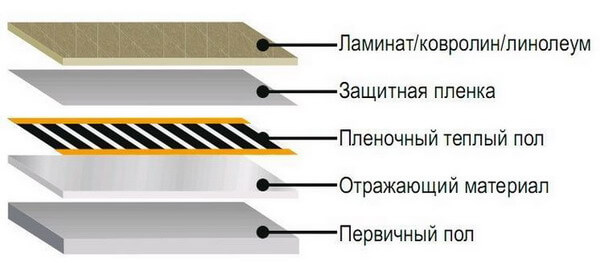

We make thermal insulation

In order for the heat to go up (to the room), and not down (to the lower floors or to the foundation), it is necessary to take care of high-quality insulation of the base under the film warm floor. For this, penofol is best used. The material is thin, so the ceiling height does not noticeably change after laying.

Since one of the sides of penofol is self-adhesive, difficulties in warming should not arise. The joints between the sheets must be sealed with foil tape.

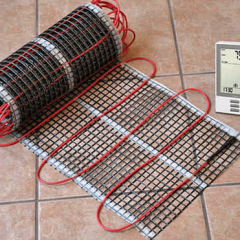

Lay the film

Now that the foundation is already completely ready, you can safely proceed to laying the film warm floor under the laminate with your own hands.

According to the scheme, you must spread the material on the surface. If you need to cut a specific piece, do it in appropriate places.

We note several requirements for laying an electric heated floor under the laminate:

- it is forbidden to lay overlap sheets, only butt to butt;

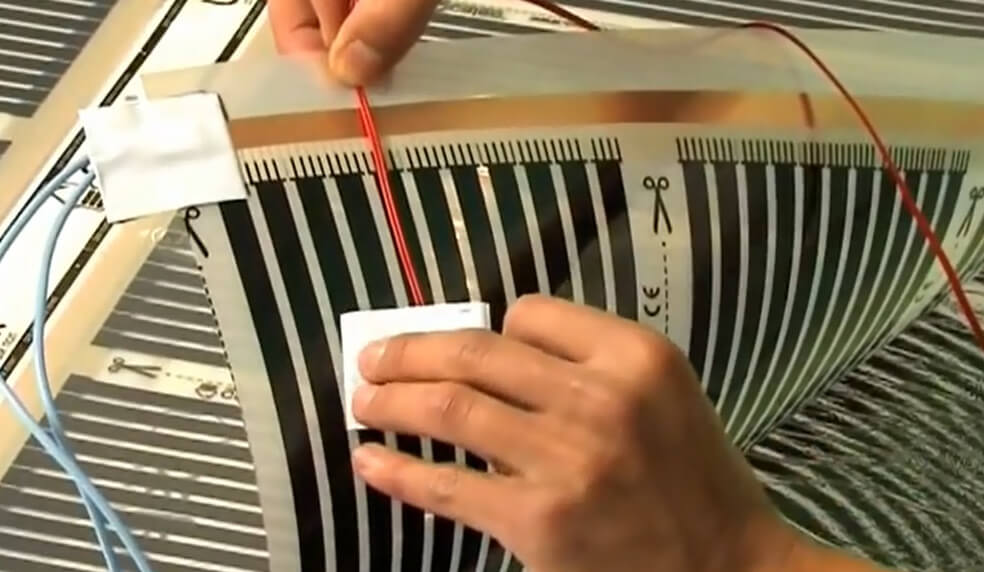

- the sheets should be placed so that the contacts are directed to the wall on which the thermostat is installed;

- the copper side should be down (adjacent to the base).

Next, install the thermostat in a suitable place. It is better to do this in a strob on the wall, next to sockets (for convenient connection to the network).

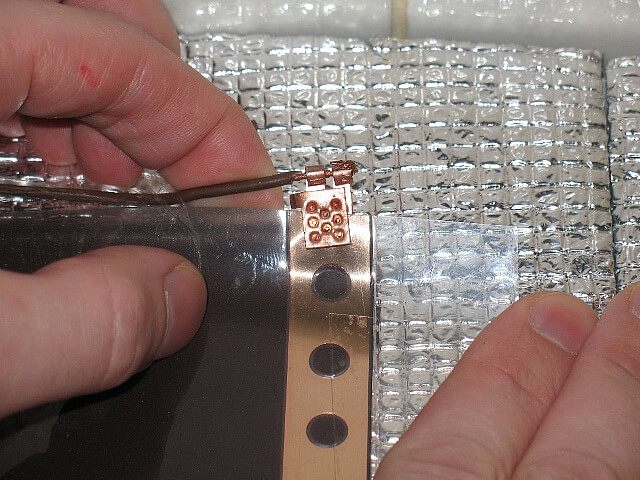

After that, the film is connected to the thermostat using contact wires, which are clamped with special clamps.

It should also be noted that all places of clamps and independent cuts of the material must be insulated with bitumen insulation!

From the thermostat you need to bring out the temperature sensor, which will be connected to the underside of the film coating. To do this, a special strobe is created at the base, with a length of not more than 30 cm. The sensor is placed in a protective corrugation and installed under the heater sheet. Be sure to put a layer of thermal insulation under the temperature sensor, otherwise a noticeable error may occur in the accuracy of the measurements, which will affect the efficiency of the system. You can connect a film underfloor heating under the laminate without a thermostat, but in this case, the energy consumption will increase, and the temperature control will be completely absent.

When all contacts are connected and insulated, you can proceed to the verification test. To do this, turn on the thermostat in the network and check that the entire surface is evenly heated. It is also recommended to check the coverage with a multimeter for the correspondence of the nameplate resistance with the real one (the value should not exceed the difference of 10%).

If everything is correct, you can lay a protective polyvinyl foam film on top of the warm floor and proceed to decorative surface finishing with a parquet board or laminate.

Also to your attention are visual video tutorials, where you can see the features of each of the stages of installation:

Useful tips from the masters

To simplify the process and make the electric underfloor heating the laminate more durable, we offer you some useful tips:

- Install the temperature sensor near a cold wall to adjust and control exactly the coldest point of the room.

- In no case do not fasten the heater sheets with nails or self-tapping screws, as this can cause a system failure. Use only foil tape.

- The infrared film is easily damaged by mechanical stress (if heavy furniture is pressed on it). Make sure that there is no heater under all heavy objects.

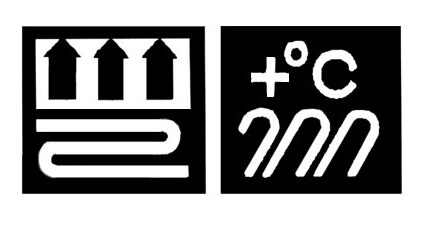

- Take the choice of laminate for a film underfloor heating seriously. Not everyone can function normally with a floor heating system. Those models that are designed for heating have a corresponding logo:

- Make sure that no other heaters are installed on the floor (e.g. oil heater) Otherwise, overheating of the film and its failure may occur.

- One piece of coverage should not be longer than 15 meters.

- Be sure to implement grounding a heater. To do this, glue the foil adhesive tape around the perimeter and diagonal, which connect the other end to the grounding contact.

- Do not lay film underfloor heating at sub-zero temperatures.

- Check your home wiring so that it can withstand the loads from this heating system. If it turns out that RCD, circuit breaker and the diameter of the wires is not suitable, replace all the elements with more powerful ones.

That's the whole technology of laying the film coating! As you can see, installation of an electric heated floor under the laminate is even possible for a person who does not have the appropriate experience. We hope that our step-by-step instructions with photos and video examples helped you to complete the installation work yourself!

Similar materials: