Need a circuit to connect the pump to the float

Good afternoon! I will say right away - I'm not an electrician. I am engaged in water supply and heating. Now there is the following task. There is a three-phase pump. The brand is unknown and there is no way to find out. But the current in the phases was measured by ticks (59A). It is necessary to provide the following pump operation algorithm. When lowering the float in the storage tank, the contacts of the control circuit of the magnetic starter are closed. When the float is raised, these contacts open and the pump turns off. And so the cycle repeats in automatic mode. Everything seems to be clear. But there is one more condition. During a power outage, it is necessary that the pump itself does not turn on regardless of the position of the float. And further. What current does the coil consume in the magnetic starter? You must know this to select a control cable. Its length is about a kilometer. Therefore, I do not want to overpay for the cable. I ask the professional electricians to excuse me if my questions are trifling. Thank you in advance.

Our answer:

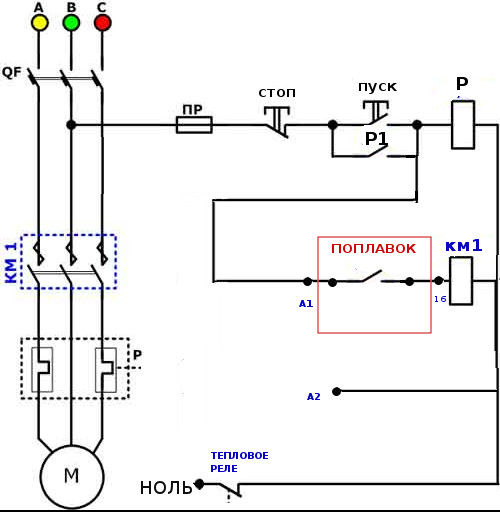

Hello. We recommend assembling the control box directly next to the pump motor. It will be easier to maintain. Wires to the level sensor, select two conductors of 1.5 mm each. With this cross section, the signal voltage will not drop significantly. The control circuit is one of the recommended ones with a float device and a limit switch.

The control circuits are powered by a voltage of 220 volts. There is a START / STOP button post, the pickup itself is made on the intermediate relay R. When the START button is pressed, relay P is drawn in, contact P1 closes the circuit, and the voltage is applied to the contacts of the float, and depending on its position, the KM1 starter works. When the voltage is turned off or the STOP button is pressed, the power to the relay stops and the circuit is disassembled.

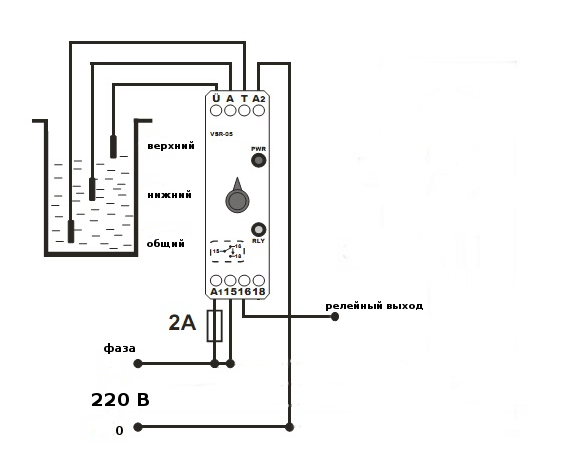

The disadvantage of this scheme is the weak point, the contacts of the limit switch, they have a limited operating time and poor reliability. We recommend that you upgrade this control circuit of the pump electronic control unit and the three-wire cable from the level sensor. Three stainless steel electrodes are immersed in the tank - common; lower; upper tank fill level. The control unit displays the status indicators of the device. Reaching the upper electrode, the circuit turns off the pump motor, dropping below the lower level of the electrode, the pump turns on. The depth of the electrodes is controlled by the hysteresis of the pump. That is, you can adjust the ratio of time between pump operation and downtime. Frequent activation of the pump reduces engine life.

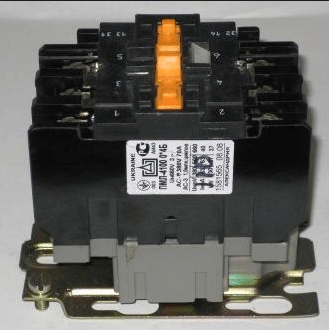

Relays USR-05 in the diagram mark the connection points of the relay. A1 phase from relay contacts R. A2 zero from the control box zero bus. 16 relay output to the pump motor starter control circuit. This scheme exceeds the previous one in reliability, the service life is much longer since there are no moving parts in the level sensor circuit. In the circuit it is possible to use KM1 as a starter -

PML 4100 starter on 63A.

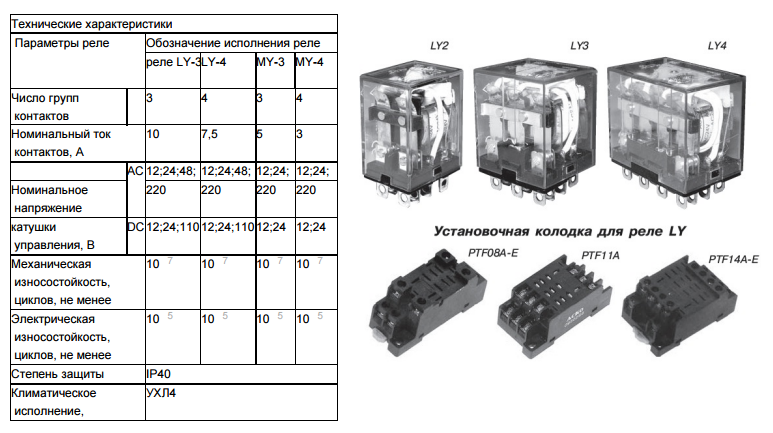

As an intermediate relay P - relay intermediate MY3, 3A AC-220V:

The disadvantages of the first scheme also include the lack of protection against the disappearance of one of the phases.

At the same time, the most expensive in the circuit burns out: an electric pump. To correct this situation, it is necessary to add two additional relays by connecting one end of the relay winding to phase A and phase C, respectively, and connect the second ends of the windings to "0". Normally open contacts (one from each relay) are connected in series and included in the gap of the relay coil “P”. Now, in the absence of any phase, pressing the “start” button will not lead to a voltage supply of one or two phases to the pump.

Instead of these relays, you can use the lack of phase relay, but there have been cases of its incorrect operation with a voltage difference on one of the phases, as a result of which the pump did not turn on.