How to ground a metal hose in accordance with the PUE

What causes the need for grounding

Grounding of electrical equipment, armored cables, as well as wiring laid in a metal hose creates the conditions for protection against electric shock in case of breakdown of the insulating sheath of current-carrying elements in them.

When the cable insulation resistance drops below normal, the metal hose will be exposed to water. leakage current, which on the grounding jumper will go to the ground. If a person touches it, another circuit is created, parallel to grounding, but since the resistance of the human body is much greater than that of the grounding bridge, an insignificant current value, safe for health and life, will pass through it. According to the PUE, when installing cable lines, the metal hose, which serves as a protection for wiring, must be grounded and it must be done in accordance with the requirements of regulatory documents (PUE p. 1.7.76, see Chapter 1.7).

How to ground a metal sleeve

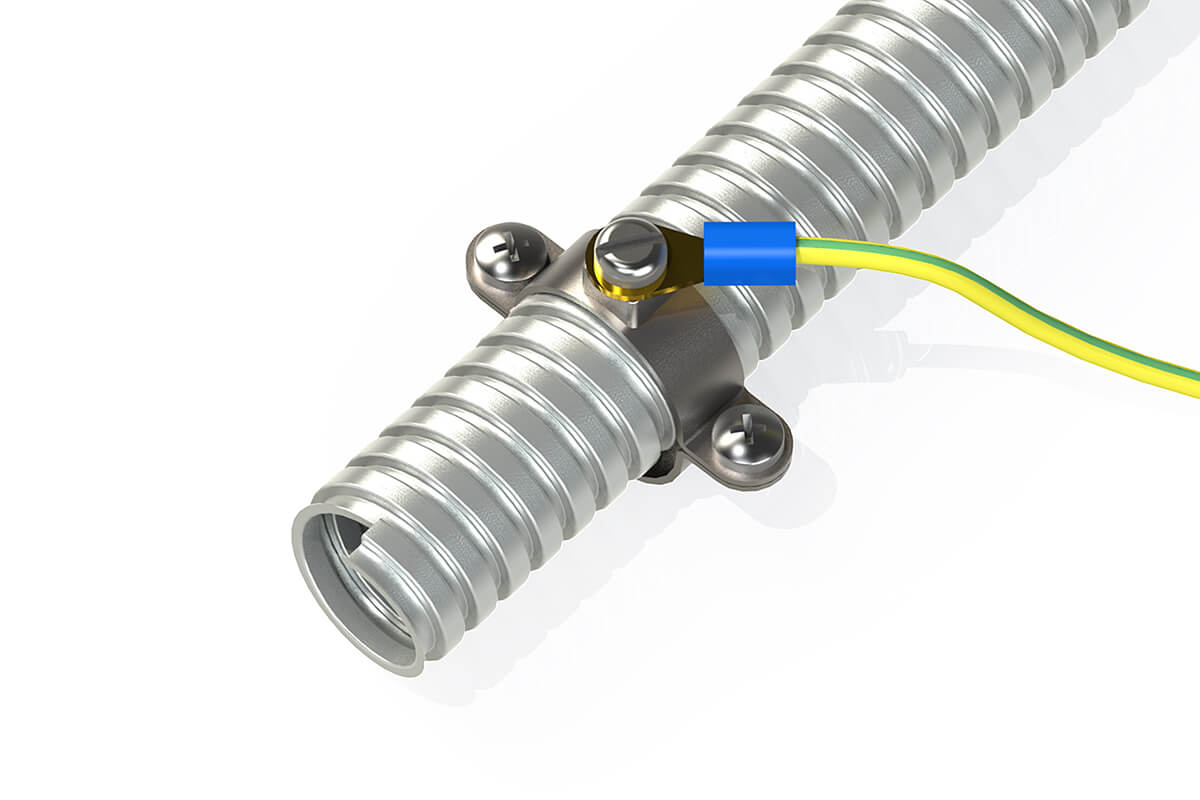

Before proceeding to the consideration of grounding technology, it should be noted that the grounding of the cable line is superimposed on both sides, at the beginning and at the end of the line. You can fix the grounding jumpers on the surface of the metal hose in two ways: using soldering or with a metal clamp.

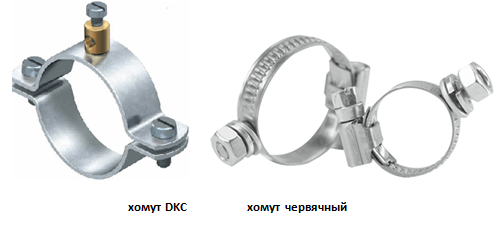

Soldering of grounding conductors to ensure reliable and durable contact is usually used by specialized electrical organizations. Since this method is not always available, in particular, when wiring is done with your own hands, it is worth resorting to tightly wrapping clamps. Some of the most common patterns are shown in the photo:

The overlays of these devices are pre-cleaned to a metallic sheen. The threaded fasteners at the jumper connections must be tightened tightly, after which it is recommended to apply a layer of lubricant. For this purpose, lithol can be used. In order to ensure guaranteed electrical safety during operation, it is necessary to periodically monitor the reliability of the point of attachment of the conductor to the metal hose, as well as its condition for breakage.

Grounding conductors can be made of steel, copper and aluminum.Their minimum cross-sections should correspond to the following values: copper - 4 mm2, aluminum - 6 mm2 (PUE p. 1.7.126). The diameter of the steel wire for indoor installation is 5 mm, and outdoor diameter is 6 mm. The ends of the conductors must be pressed into the lugs. Bare conductors made of aluminum, without PVC insulation, are not allowed to be used as jumpers.

What to use as an earthing switch

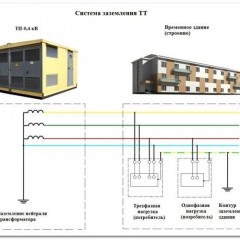

The free ends of the jumpers connected to the metal hose must be grounded, that is, connected to the ground loop, which can be used as natural groundingand artificial. If the situation allows, the most common option for connecting reinforced concrete structures and foundations of buildings to the reinforcement as an artificial grounding conductor according to the PUE (paragraph 1.7.109) is allowed. Connection to underground steel pipelines is not forbidden, but only if they do not serve to transport combustible substances or natural gas to casing pipes of drilled wells. It is allowed to connect cables laid underground to the metal sheaths, exceptions are products with aluminum current-carrying conductors (PUE p. 1.7.109). If there are no such connection options, it is necessary to equip an artificial grounding device. As the simplest device, you can use a metal conductor inserted vertically into the ground.

A more complex, and therefore reliable option, is the installation of an grounding circuit, consisting of a group of such conductors interconnected by horizontal jumpers.

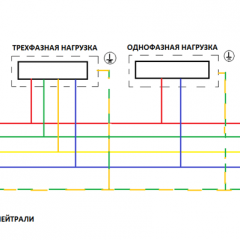

The issue of arranging an earthing switch is relevant for electrical networks with an earthing system TN-C and TN-C-S. For power supply systems using the principle of TN-S, which has not yet found wide application, the task is greatly simplified. As a grounding device, a bus connected to the protective neutral conductor PE is used.

That's all I wanted to tell you about how to make the grounding of the metal hose according to the PUE. We hope that the information provided and photo examples were useful to you!

It will be interesting to read: