How to connect wires with a bolt - step by step instructions

Bolted connection is often used to connect wires in the home and in the workplace. For switching lived in a junction box, this is far from the most successful option due to the cumbersome connections, but in the absence of other options, you can use it. The photo below shows what the finished connection looks like:

It is especially convenient to use such a solution if there are no special sleeves and terminal blocks, with connection of aluminum with copper. How to make a bolted connection? Since no special tools are needed for this method, it will be easy and simple to execute. But, despite this, this technique also has its drawbacks: dimensions and a large amount of insulation. In order to ensure safety, a lot of insulating material is required.

To properly perform the bolted connection of two wires (aluminum and copper), you must have certain tools and materials. Namely:

- nut and bolt;

- metal washers (three pieces are enough);

- tightening tool - pliers or a wrench may be suitable for this;

- insulation tape (cotton).

As soon as everything you need is collected and prepared, you can begin to work:

- Prepare the wire. To do this, the ends are cleaned by five centimeters. Maybe more when connecting large cross-section wires or when using a large diameter bolt.

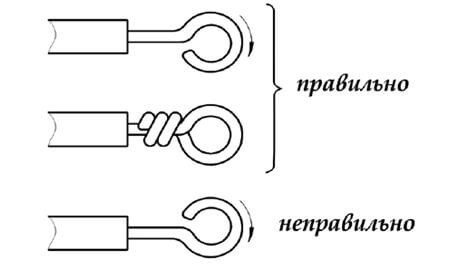

- At the end of the conductor you need to make a loop. Its diameter should correspond to the diameter that the bolt has (for example, 6 mm or 10 mm). But the exact diameter “by eye” will be extremely difficult to twist, so it is best to do this using a bolt as a mandrel.

- A metal washer is put on the bolt, and after it a loop from the first wire.

- Then put on the next washer and already on it the next loop. Thus, when connecting an aluminum and copper core between them, a washer is obtained from the washer and no direct contact is formed, which prevents the destruction of the conductors. When connecting two copper cores, you can do without a washer between them.

- After that, put on the third washer and tighten the nut.It is important that the hinges are bent towards the nut (clockwise), and the washers are wider than the area of the conductor in the loop so that when tightening the loops do not loosen or crush. Repeat the order of the elements: washer, loop, washer, loop and washer and nut.

- The bolted connection is completed by insulation of the conductive part with a wide insulating tape.

If you want to connect two wires that are made of different materials, then it is better to apply terminal blocks WAGO or bolt fastening. When repairing old electrical wiring, where the wire differs from each other in material, this will be the most optimal solution. If the bolted connection is made in accordance with GOST and in accordance with all norms and requirements, then no difficulties will arise. Also if it was decided replace wiring in the house, then you need to remember that twisting, according to the PUE, is prohibited, and instead of it it is better to use soldering (this is if the material of the products is the same). If the metal is different, then, as an option, a screw and bolt connection.

The video below demonstrates how to connect the wires with a bolt:

Now you know how to make a bolted connection of wires and when it is advisable to apply this method of switching current-carrying conductors. We hope the information provided was useful and interesting for you!

We also recommend reading: