Testing non-linear surge arresters

The importance of testing

Perhaps the main regulatory document that we use and which we most often encounter in the production of acceptance tests is the PUE. With regard to surge suppressors, it has a chapter 1.8, and specifically paragraph 1.8.3. It sets the standards and scope of tests for arresters and gate arresters.

In addition to acceptance tests, in accordance with the above documents, the following tests can be carried out:

- periodic;

- qualification;

- typical.

A qualification check of these devices is necessary in order to determine whether the enterprise is ready for production in this volume. This applies to the first industrial series or installation lot. An important step here is to check the explosion safety. During operation of the arrester due to the influence of various factors, one of which is an off-design mode of use, increased pressure may occur inside it. As a result, an explosion is possible, which entails damage to equipment that is installed nearby, as well as, most importantly, people working at the facility.

Let's take a closer look at the acceptance tests. As noted above, they are governed by Chapter 1.8 of the PUE, paragraph 1.8.3. If we reduce all the data from it, we get a convenient label:

Thus, for the arrester there is a technique for measuring the resistance and conductivity current. How to check these parameters will be considered below.

Conductivity current measurement

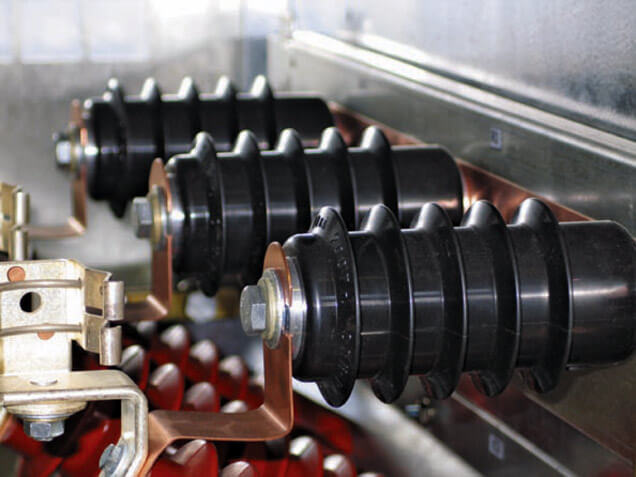

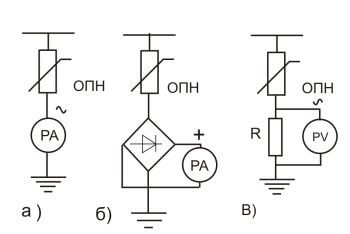

The picture shows various connection schemes for conducting arrester tests related to the measurement of conductivity current:

Basically, the standard value of the conductivity current is indicated by the manufacturer in the technical passport to the product. This value is taken on the basis of tests carried out at the enterprise and directly depends on the greatest long-term applied voltage.

Measurement of the current value is carried out by an ammeter or milliammeter. The laboratory power supply is connected to the conclusions of the assembled circuit. When the load is applied, current measurements are taken. The load shall be in accordance with the maximum permissible continuous voltage.

It should be noted that work should be carried out at a steady-state ambient temperature of 20 ± 15 ° C, on surge protectors that are cleaned and wiped dry, which must first be disconnected from the network.

Insulation resistance measurement

Based on the data presented in the above table, it is clear that when testing arrester up to 3 kV, it is necessary to use a megohmmeter with a voltage of 1000 V, if more than 3 kV, you need a megohmmeter at 2500 V. The measured resistance for an arrester up to 3 kV should be higher than 1000 mOhm, voltage from 3 to 35 kV - should be within the range recommended by the manufacturer, higher than 110 kV - should be at least 3000 mOhm, at the same time, the result should not differ by more than ± 30% from previously performed tests or values specified by the manufacturer.

About, how to use a megaohmmeter, we told in the corresponding article, which we strongly recommend that you read!

Remember that only an electric laboratory that has a certificate for this type of event can guarantee safe and quality work. At the end of the measurements, a protocol is drawn up to conduct the tests of the arrester. It indicates the name and type of the limiter, the values of measurements of the insulation resistance and conductivity current, weather conditions, as well as the instruments with which the measurements were made. A sample protocol is shown below:

Finally, we recommend that you familiarize yourself with the useful material provided on the video (the quality of the video is not very good, but still the information is clear):

That's all we wanted to tell you about the arrester test procedure. Now you know how the work is carried out and why you need to do it!

Interesting topic:

Hello! What does basic arrester resistance mean?