How to organize the grounding of cable trays

Metalwork cable trays

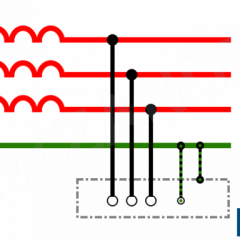

Although the trays are interconnected by means of bolts, due to which they have a continuous connection of the structure and some electrical conductivity, they must be connected with additional jumpers. Indeed, according to GOST 10434.82, the route can be considered grounded only with the use of jumpers.

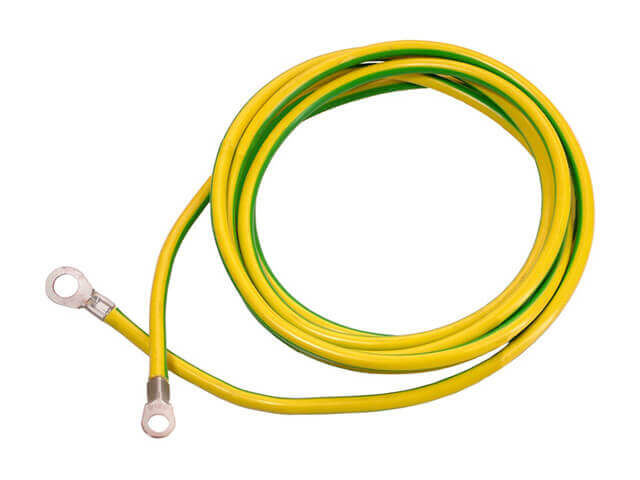

You also need to know which wire section to use in order to ground the cable management tray. If jumpers are used as conductors, they must have a cross section of 4 to 6 mm², and the insulation must have the correct color markingwhich consists of yellow and green.

If you independently make such jumpers, then you can use a flexible multicore wire of the brand PV-3. However, it should be remembered that such a wire should have a tip, basically it is installed using crimping.

It should also be noted that the bolts connecting the protective conductors cannot be used for other purposes, for example, for connecting the sides of the trays, or for attaching to supports. Some manufacturers put special washers that have teeth in the kit for the trays. Such washers provide increased contact reliability, and also cut off the likelihood of loosening clamping nuts or special tires.

The benefits of wire trays

If you compare this embodiment with other products, then the wire trays have a lot of positive features, here are some of them:

- installation is not too expensive;

- the products themselves are much cheaper from sheet products, as well as ladder types;

- cooling of the wire is much better than in designs with closed boxes;

- in order to ground the tray, you can use a fairly simple scheme;

- quite a bit of dust accumulates inside, many times less than in galvanized or metal structures;

- in terms of load, cable trays made of wire are not inferior to others, for example, sheet;

- for use there is no need to buy expensive additional accessories.

It will take very little effort to ground the cable tray, because it initially has excellent EMC performance.Products made from polyvinyl chloride are not able to provide high-quality interference suppression. Because of this phenomenon, metal cable trays manufactured by the DKS company began to be widely used by mobile operators.

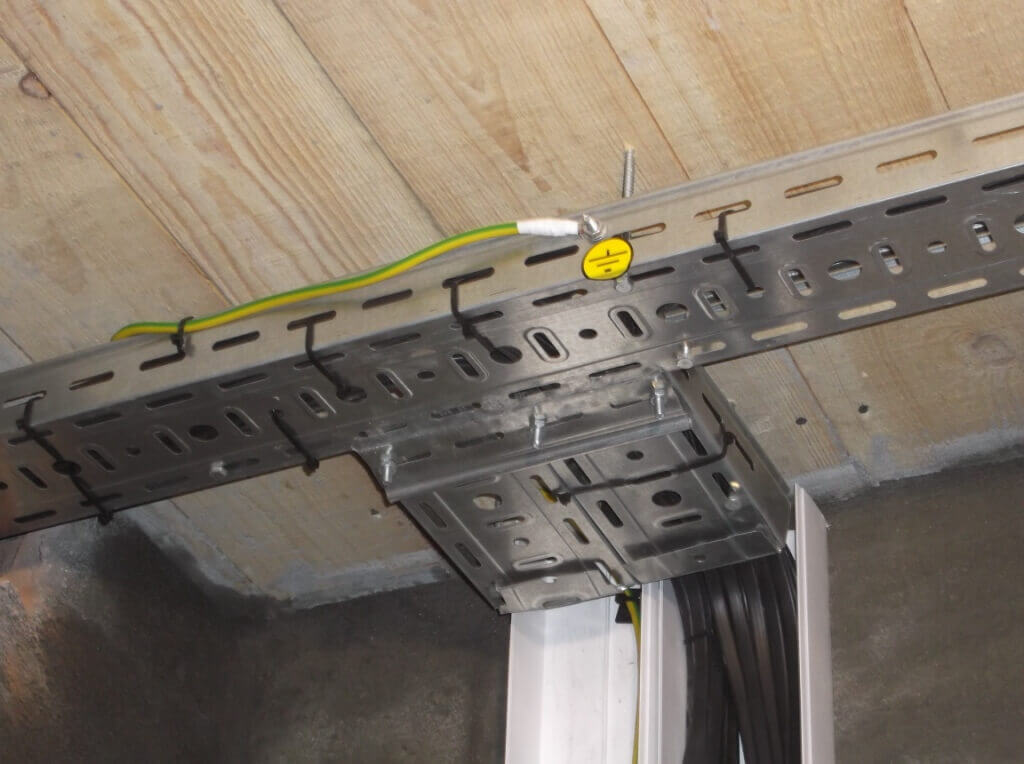

According to the PUE, it is necessary to ground all trays. The conductive supporting structure for the wires needs complete, comprehensive protection. And the work itself is carried out in full compliance with the standards that are in SNiP. For example, trays of the DKS brand are grounded at least at two points - at the beginning and end.

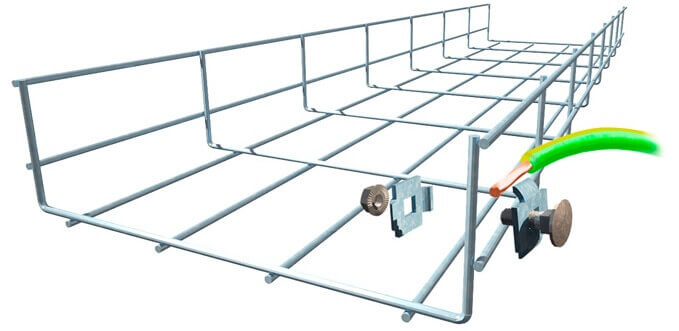

The wire channels for cable laying are conductive, therefore, they need to be connected to a potential equalization system. Unlike the joints that are available in tape and sheet channels, wire trays have less contact and therefore less conductivity. For this reason, a special terminal is used, due to which the desired resistance value is provided between the cable system and the ground bus.

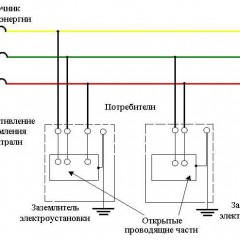

In order to ground the trays, it is necessary to use several special electrodes. They must have good contact with the ground and the conductor that connects the installation to ground. Exclusively for each object, you must separately select the ground point. It is at this point that the voltage of the electrical equipment will have a value of zero. Soils such as peat, clay and loam are ideal for grounding.

Removable Tray Lids

When installing the cable route, you must take into account that the covers of the trays are not part of this design, therefore they should not be grounded. For the reason that the removable cover with grounding initially has an excellent level of protection against electric shock. The products provided by DSK are mounted very simply and quickly. For installation, it is enough to choose the best method: by drilling holes in the wall, or using suspensions. On each of the surfaces of this design there are special contours and additional accessories. To fix the grounding wire, you can use a bolt brand M5.

It is necessary to properly and constructively approach this work, because thanks to this, you can be sure of protection against electric shock during a short circuit, which is immediately transmitted to the base case.

Connecting the wire to the structure

In order for the grounding to work properly, it is necessary to determine at what points to connect the wire to the structure. The rules on this issue are contained in the "Instructions for the design of grounding networks." Based on this document, it is necessary to connect sections of profiles, trays, cable runs and blocks, steel pipes, and ducts that serve as holders for laying wires and protecting against damage. All these elements must have a continuous electrical circuit. Grounding must also be attached to the trunk in at least two places. However, if the length of the highway is less than two meters, then you can connect to the integrated highway in only one place.

Despite the fact that these grounding rules apply to explosive areas, it is best to use them in all cases, and ground at two points. It should also be noted that not all explosive areas can be installed wire trays.

Additional features

If we talk about the process of grounding cable trays, some companies recommend that it be carried out at intervals of twenty meters. However, according to experts, grounding should be every ten meters. Such grounding is used when the structure is operated in adverse conditions.

For correct and reliable connection to the cable holder, it is recommended to use special, and sometimes reinforced, terminals. They are sold in almost all markets or construction hypermarkets. Installation is very simple.First, you need to attach the terminal to the side wall of the tray, then pass the cable through its hole. In the place where the wire is in contact with the hole, insulation must be removed in the terminal.

Now you know how to ground cable trays and what requirements you need to consider when organizing this kind of protection. We hope the information was useful and understandable to you!

Related materials: