What is a solid state relay and why is it needed?

Application area

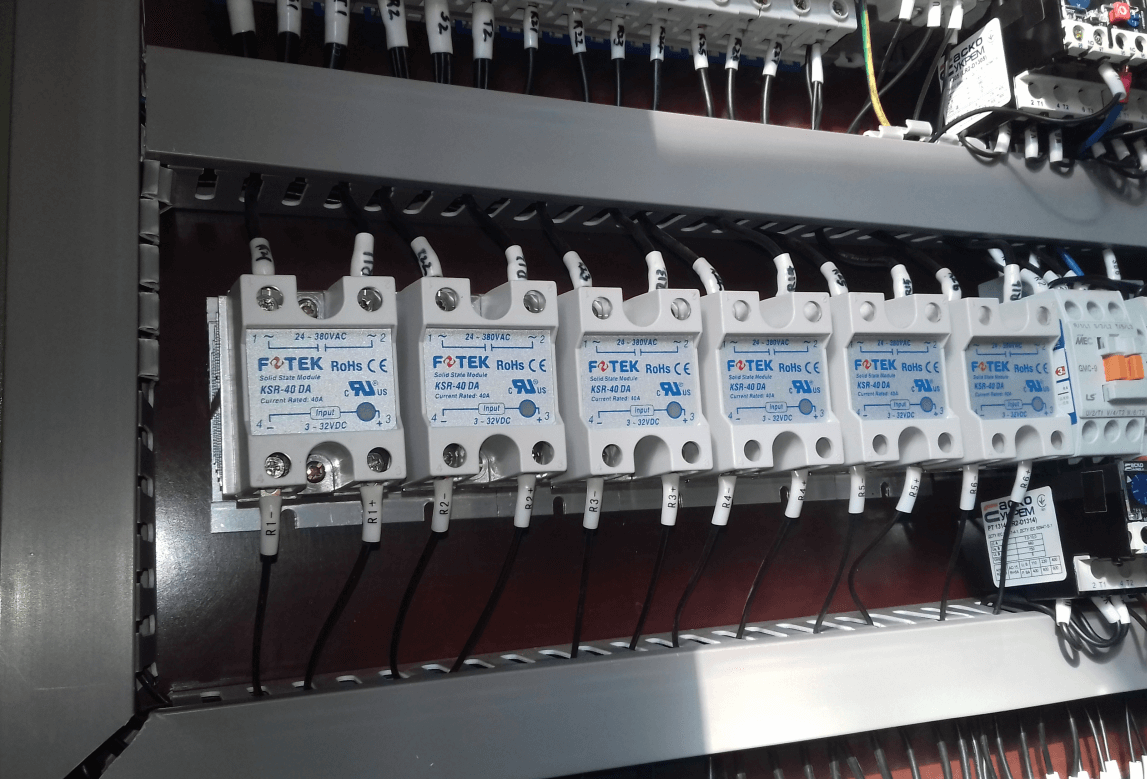

These devices are used in industrial automation, telemetry, mining and metallurgical mechanisms, the chemical industry, medical equipment, military electronics and other fields.

From the name "solid state" is meant the absence of any moving parts. Instead of a contact group, they are replaced by an electronic power switch. Due to this, this type of apparatus does not create an arc during switching. This property is very useful when used in the chemical industry, in places of severe gas contamination, as well as in those places where the abrasive dust content is high. Also, the reaction time to the incoming signal should be instantaneous, thousandths of a millisecond, the absence of hysteresis, a wide temperature range, noiseless switching.

Device Features

The absence of transients in the form of an arc and sparks increases the operating time by several times. If a normal contact, at best, is designed for 500 thousand switching operations, then the power electronic element does not have such data. Even at a higher cost, electronic relays are also more profitable to use from the point of view of economy, because to turn them on and off, you need to spend less energy compared to a traditional electromagnetic relay, and the powerful load is controlled directly by microcircuits.

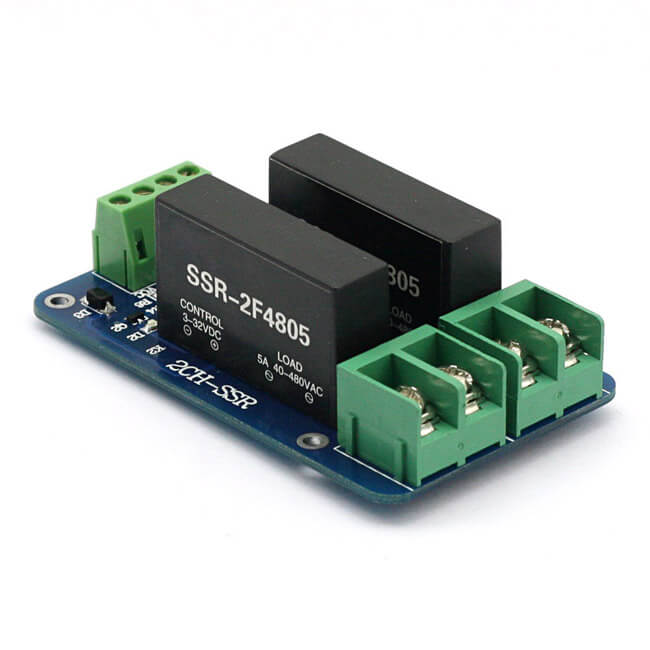

The nomenclature of product types is quite large: from miniature sizes to devices that control the motors of actuators. There is also a difference in the type of switching voltage, for direct and alternating. This must be considered when choosing a solid state relay.

Each device has its own weaknesses, and solid-state relays are no exception. The Achilles heel of electronic keys is the sensitivity to the load current, the excess of which electronic components are hard to survive, and when exceeded several times, they completely fail. Therefore, when selecting or replacing the device, you must responsibly approach the protection of the key with protective devices. You need to select the keys two or three times more current, from the switched load. In addition, it is important to equip the power circuit with fuse-links or fast special class B machines.

Design

A solid-state relay device is an electronic circuit board consisting of a power switch, an isolation element, and a control unit. As power elements can be used:

- for DC circuits: transistors, field effect transistors, MOSFET composite transistors or IGBT modules.

- to control alternating voltage circuits, triac switches or thyristor assemblies are installed.

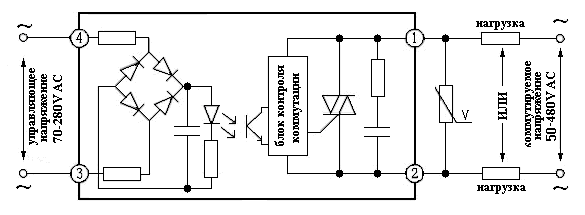

Optocouplers are installed as a decoupling element - this device consists of a light-emitting element and a photo receiver, separated by a transparent dielectric. The control unit is a voltage and current stabilization circuit for a light-emitting element in an optocoupler.

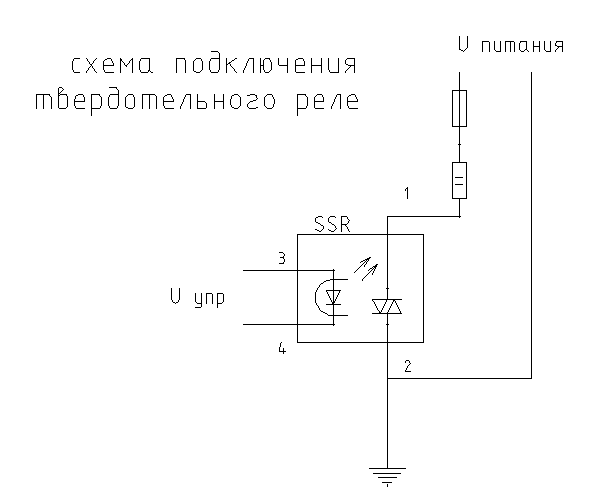

As can be seen from the circuit, the control inputs are numbered 3 and 4, and the output is terminals 1 and 2. In this circuit, the input signal can be from 70 volts to 280 alternating voltage, and the voltage at the load can reach 480 volts. It does not matter which contact the consumer is located before or after the relay.

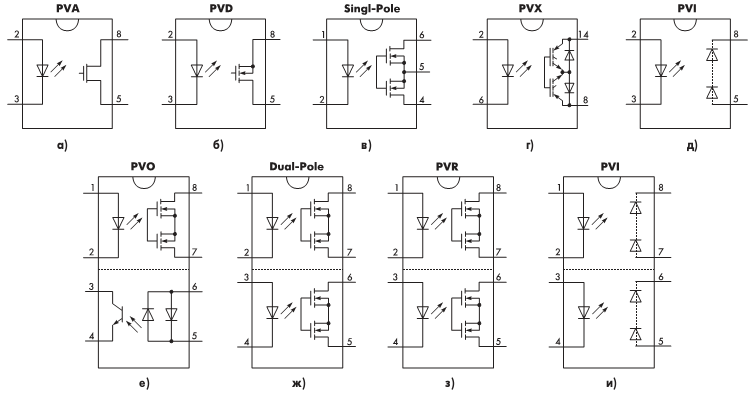

The symbol of the solid-state relay in the diagram may look like this (to enlarge, click on the picture):

As for the connection scheme, in it the device is installed after the load, connecting it to the ground. With this connection, in the event of a short circuit to ground, the relay is excluded from the current flow chain.

Finally, we recommend watching a video that clearly demonstrates how a solid-state relay works and what it consists of:

So we examined the purpose, scope and design of the solid-state relay. We hope the information provided was useful and understandable!

Surely you do not know: