Frequent errors when heating concrete

What causes improper heating

Many do not understand that the wrong approach to concrete work leads in the future to extremely unpleasant consequences. Avoiding them is simple enough - you just need to decide on a high-quality method of heating concrete and clearly adhere to its technology.

To increase the speed of construction, many different methods of heating concrete are used. Among them, it is worth highlighting a heating wire, electrodes and others. These methods require the participation of experienced professionals and are distinguished by high labor costs.

The unskilled use of warm-up techniques leads to a host of errors. It should focus on the most popular. They are found in almost every second construction site. As a result, cracks appear on the structures, which subsequently leads to destruction. It is unlikely that anyone will be interested in such prospects in the future.

Common mistakes

Electrode heating of concrete

Electrode heating of the mixture is often accompanied by the following errors:

Error No. 1. The electrodes have a low contact area with concrete, due to their design features. As a result, warming up becomes poor quality. Also, air bubbles may appear between the electrodes and the mixture. They lead to boiling water, blocking the spread of thermal energy in concrete. It concentrates in one place, forming cavities.

Error No. 2. Inside the concrete is a reinforcing metal "skeleton". If the electrode touches it during immersion, this instantly leads to a short circuit. Thus, expensive equipment that may not be repairable fails. If there is nothing more to heat, then the technology of solidification of the mixture is disrupted.

Error No. 3. Increasing current density in the direct contact area of concrete and electrodes. This is fraught with a slowdown in the rate of hydration, local overheating and the formation of a porous structure. It is noteworthy, but outwardly it is impossible to detect the mistake made. You can learn about it in the future, when the structure begins to collapse ahead of time.

Concrete heating with heating cable

Errors occur when heating concrete with a heating cable:

Error No. 1. Few of the builders pay attention to the connection diagram of the heating elements. In particular, if none of them has an education in the field of electrical engineering. As for the integrity of the wires, this almost never happens. They are simply laid out on the surface. If the integrity is violated, then the heating cable cannot fulfill the role assigned to it. Or heating occurs only in certain places. Uneven heating leads to cracks and to the rapid destruction of the internal structure of concrete.

Error No. 2. When laying wires, you should pay attention to their insulation and proper location. Many people forget about this. The cable should have an optimal length - no more and no less than the laid. Otherwise, it is overrun, which leads to an increase in the duration of construction work.

The negative aspects of using a heating cable are as follows:

- Large capacities are needed to heat a significant amount of concrete. Often they are not at the place of work.

- It will take a lot of electrical calculations. It takes extra time and effort.

- A very limited number of specialists are able to properly lay the cable. Not all companies can afford to keep this on staff.

These errors are the most common when concreting and heating in the listed ways. Knowing about them in detail, it is better to try to avoid them. After all, it is better to do everything right right away than to spend money in the future on dismantling the old and installing a new design. Sometimes this requires the complete destruction of a building or object.

What heating method to give preference

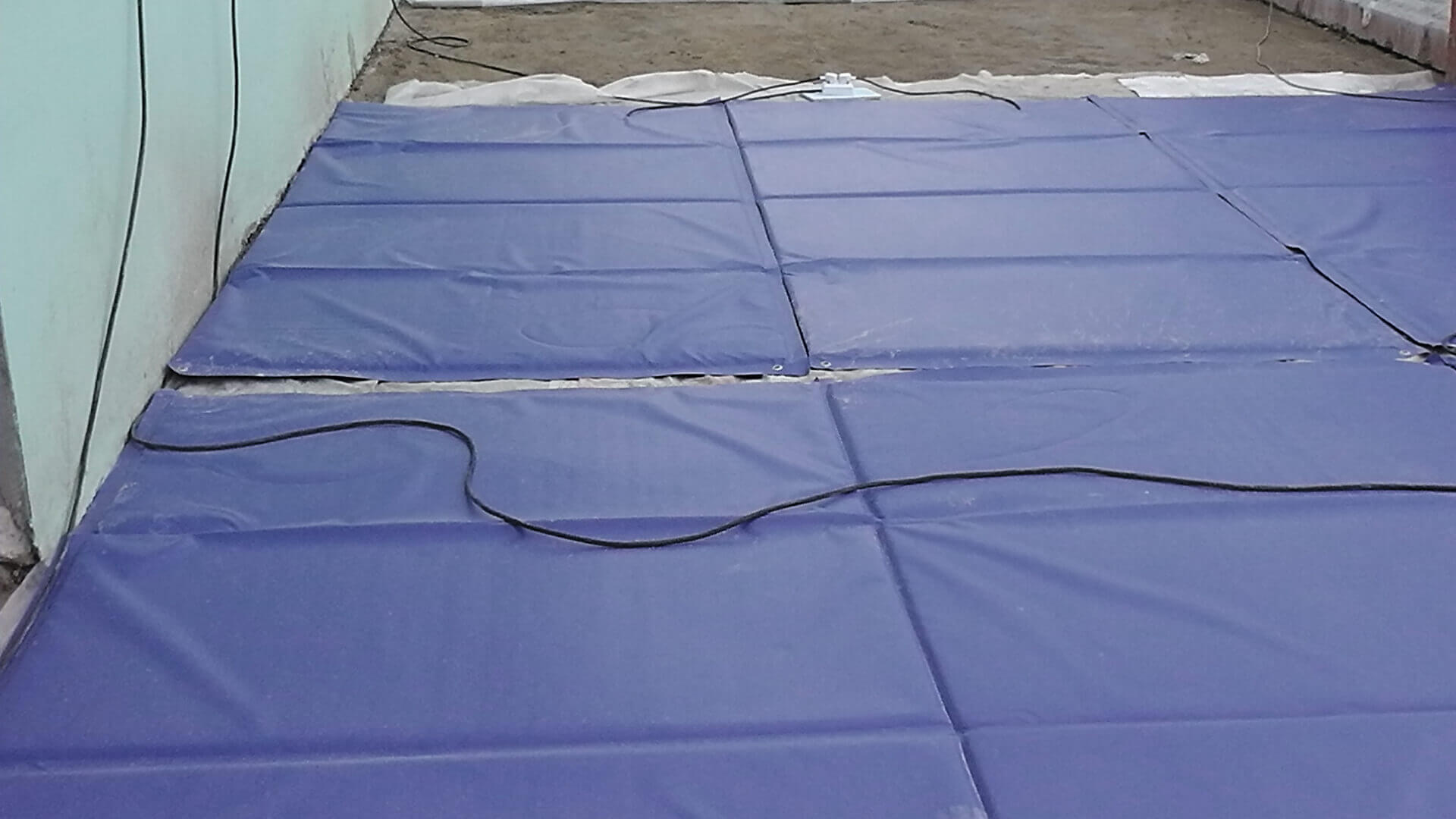

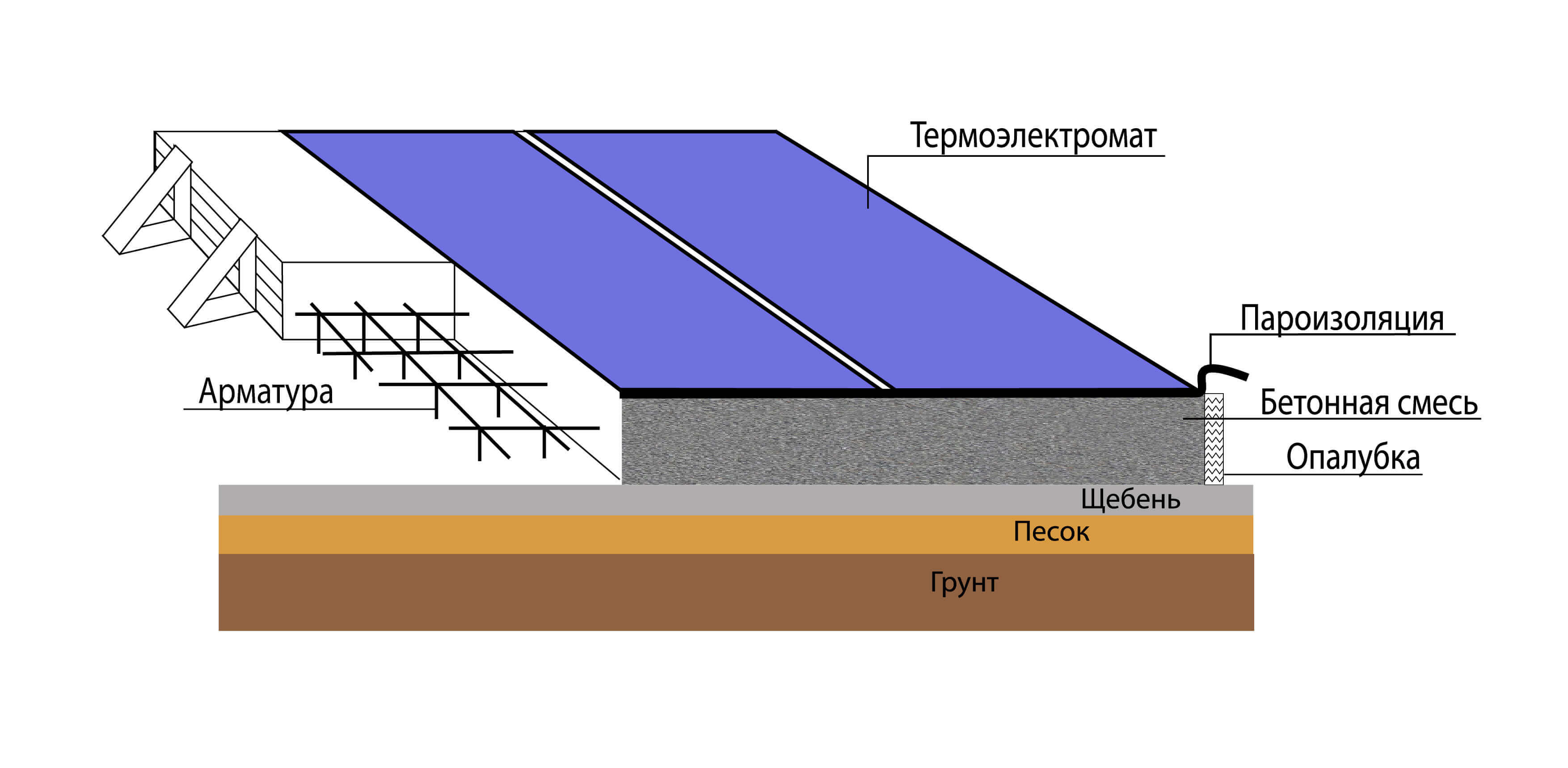

In the absence of electricians and experience in heating with electrodes, as well as with cable, you should pay attention to alternative methods. For example, cover the structure with an ordinary awning. During solidification, the mixture releases thermal energy. She will go for heating. But, the awning can be applied only when there is no frosty weather on the street. Another option is to use thermoelectromates.

Today they are available for sale, and have an optimal cost. They are laid on a concrete structure from above. They maintain the set temperature over the entire heated surface. The list of advantages of using thermoelectromates includes:

- Reducing the construction time of facilities. It will be possible much faster to move to a new stage of work, or to a new facility.

- Uniform distribution of thermal energy. Each centimeter of a thermomat emits heat in the same volume.

- Improving the quality of the design. It hardens as it should, regardless of weather conditions.

- Cost reduction. This is important, given the current economic situation and huge competition.

In the end, we recommend watching useful videos on the topic of the article: